Selective laser sintering brings both advantages and disadvantages to modern manufacturing projects. This revolutionary 3D printing technology has transformed the industry. It offers the quickest way to create prototypes and small-volume batches with remarkable precision. SLS proves to be the best choice for many prototyping and low-volume production needs because it’s faster and more reliable than FDM and SLA.

Let’s examine what selective laser sintering is. The technology uses powder bed fusion 3D printing that works with plastics. A laser sinters material without needing support structures because the powder provides enough support. The process excels at creating objects with complex geometries while delivering superior strength and stiffness. The technology also lets you stack models tightly inside the build volume – something other 3D methods can’t achieve.

SLS shows impressive capabilities but comes with its share of limitations. The printers need a large upfront investment, usually between $15,000 and $18,000. The process creates strong, reliable prints using Nylon powder (PA-12), yet produces some waste when the powder heats up before laser exposure. SLS needs specialized laser technology, making it more expensive than SLA and FDM options.

This piece reveals the hidden pros and cons of selective laser sintering that affect manufacturing success. From creating highly detailed features as small as 0.75 mm to evaluating affordability for different production volumes, these factors matter greatly when you’re thinking about using this powerful manufacturing technology.

What is Selective Laser Sintering and How It Works

Carl Deckard, a mechanical engineering student at the University of Texas at Austin, created selective laser sintering in the late 1980s. He wanted to solve a design problem by making prototypes without traditional manufacturing delays. His state-of-the-art solution has become one of today’s most reliable additive manufacturing technologies.

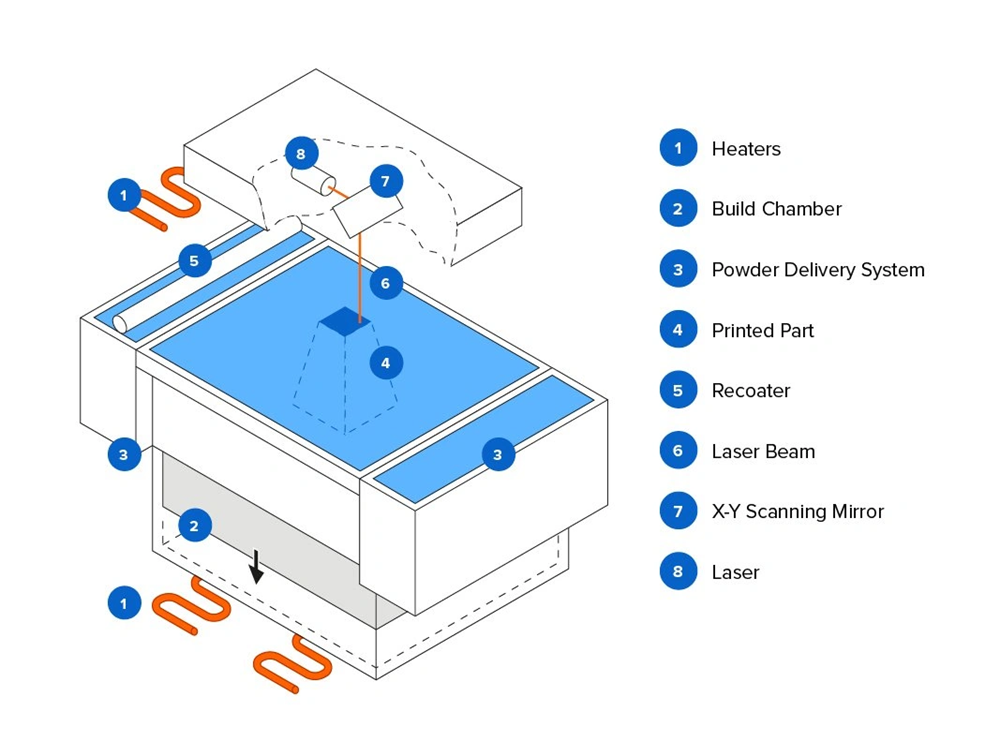

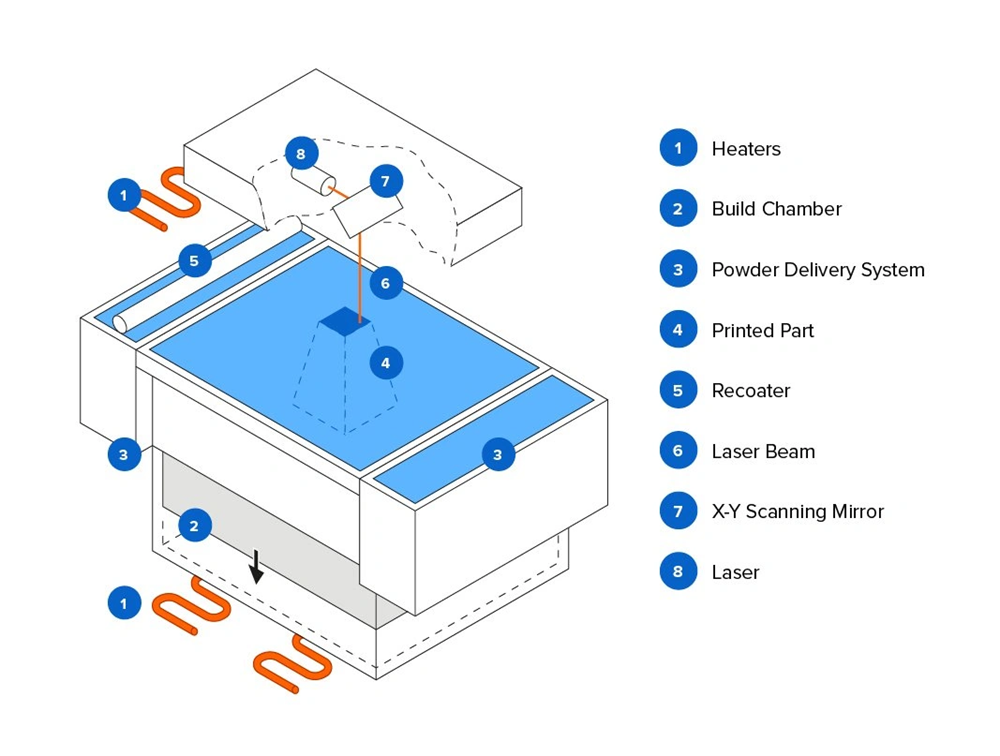

Selective laser sintering process overview

Selective laser sintering (SLS) uses advanced powder bed fusion technology. A powerful laser fuses powdered materials to create solid three-dimensional objects from digital designs. The laser heats the powder just below or exactly at its melting point. This makes particles bond mechanically instead of melting completely. The process works great, especially when you have complex geometries, because it doesn’t need support structures. The unsintered powder naturally supports the part during printing.

The SLS workflow follows a simple sequence. A 3D CAD model serves as the blueprint. The design converts into a printable format with thin, horizontal cross-sections. The laser traces each cross-section during printing. Layer by layer, the complete structure takes shape.

Powder sintering using a CO2 laser

CO2 lasers are the preferred choice in most SLS systems over alternatives like diode lasers. These lasers operate at a 10.6 micrometers wavelength in the mid-infrared spectrum. They give excellent absorption characteristics for thermoplastic powders of all types, including PA12, PA11, and TPU. The optimal wavelength helps melt and fuse powder particles better. This results in denser parts with improved mechanical properties.

The laser’s precise control will give a quality finished product. CO2 laser’s Gaussian energy distribution delivers consistent energy across the sintering area. This allows finer focus and uniform sintering. The precision helps minimize warping and thermal distortions that could affect the part’s integrity.

Layer-by-layer fusion in a heated chamber

SLS happens in a controlled environment. The build chamber needs preheating to a temperature just below the plastic’s melting point before printing starts. Preheating makes laser sintering more energy-efficient. It also reduces thermal stress that could warp the final part.

The layer-by-layer building process follows these steps:

- A thin polymer powder layer spreads across the build platform (0.1 to 0.15 mm thick)

- The laser sinters powder based on the current cross-section

- The build platform lowers after each layer

- Fresh powder covers the previous layer

- This continues until the object forms completely

The chamber needs several hours to cool before part removal. Gradual cooling helps achieve the best mechanical properties without deformation. The finished parts emerge from surrounding unsintered powder, which can be recycled for future prints.

Temperature control requires incredible precision. The heating process uses up to 5 kW of power. All three stages – preheating, melting, and cooling – need temperature control within 2°C. This strict control ensures parts maintain their quality and dimensional accuracy.

Advantages of Selective Laser Sintering in Manufacturing

SLS technology gives manufacturers many competitive advantages compared to traditional manufacturing methods. These benefits range from flexible design options to faster production, which makes SLS popular for prototyping and small-scale production.

Support-free printing for complex geometries

SLS stands out because it creates complex geometries without needing extra support structures. The unsintered powder acts as natural support during printing. Engineers can freely design hollow spaces, overhanging features, and thin walls without worrying about removing supports. This lets designers create intricate internal parts, curved channels, and enclosed spaces that would cost too much with traditional manufacturing. Engineers don’t need to redesign parts around support removal limits, which leads to better performance-driven designs.

High mechanical strength and isotropy

Parts made with SLS have excellent mechanical properties and strong layer adhesion. This creates isotropic components with consistent tensile strength, hardness, and elongation across x, y, and z axes. These uniform properties make SLS parts great replacements for injection-molded components in prototypes and small production runs. The parts are durable with high impact strength, medium flexibility, and good resistance to environmental factors.

Efficient batch production with nesting

SLS streamlines production by making the most of build volume. Parts can be arranged close together with minimal spacing. This process, called “nesting,” works like a 3D game of Tetris to pack more parts into the powder bed. Nesting software arranges parts in seconds. Operators can place parts manually for better control or let automation fill the remaining space. This helps manufacturers make more parts at once, which cuts down time and costs.

Material reuse and reduced waste

SLS shines in sustainability with its recycling features. Manufacturers can recycle up to 80% of unused powder, which reduces waste and material cost. This recycling cuts landfill waste by 50-80%. It’s better for the environment too – recycling creates only 3.1 kg CO₂/kg compared to 10.5 kg CO₂/kg for new powder. The cost savings are clear – recycled nylon costs USD 30.00-50.00/kg while new material costs USD 70.00-100.00/kg.

Fast turnaround for functional prototypes

SLS is one of the quickest additive manufacturing methods for making durable prototypes and end-use parts. The laser scans and materials need minimal exposure time to fuse. High-powered lasers can complete full-volume prints within 24 hours. Engineers can prototype parts early without tooling or lengthy setup. This means they can test and modify designs in just a few days.

Disadvantages That Are Often Missed in SLS Discussions

SLS technology has several drawbacks that affect its industrial applications, though many technical discussions rarely mention them. These limitations can affect production quality and costs in ways you might not expect.

Shrinkage and warping during cooling

Cooling creates one of the biggest challenges in SLS manufacturing. Parts shrink between 3% to 3.5% as they cool from their sintering temperature. This change in size creates internal stresses that pull the lower layers upward and cause warping, especially when you have large flat surfaces. You need to let the build chamber cool to less than 30°C before removing parts. Taking them out too early when temperatures exceed 45°C makes the warping much worse.

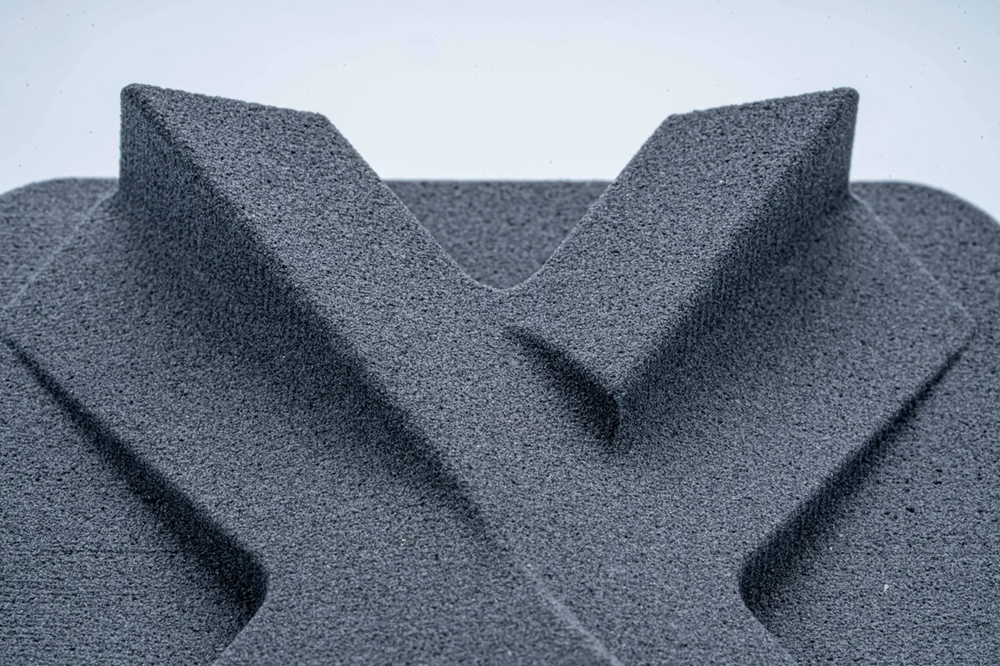

Surface roughness and porosity limitations

SLS parts are nowhere near as smooth as parts made by other manufacturing methods. While injection-molded parts have surface roughness values between 0.012–0.025 μm for high glossy finishes, SLS parts measure between 5–25 μm. Rough surfaces happen because powder grains don’t melt fully, sintering necks form, and dry powder grains press into layers that have already cured. The parts also end up with about 30% internal porosity, which affects how well they resist water and their mechanical properties.

Material constraints: mostly nylon-based

Nylon-based polymers dominate the material options, which limits what you can make. PA12 (Nylon 12), the most common material, costs about $50-60 per kilogram. The powder quality gets worse with each print cycle, so you must mix used powder with about 50% fresh powder. You lose around €2300 worth of material for every 10 kg of printed parts through this degradation.

Post-processing time and labor intensity

Hidden costs lurk in SLS production’s post-processing needs. Parts need long cooling periods—often half as long as the print time for a full build. You must then extract powder, recover materials, and blast the parts with media. These labor-heavy steps add time and cost to production.

Powder safety and environmental concerns

PA12 powder requires careful handling to protect both people and the environment. Tiny particles float in the air during handling and can cause breathing problems. The power consumption runs up to 5 kW, which raises sustainability concerns, even though SLS uses less energy than some other manufacturing methods. Safe operation demands proper ventilation systems and protective gear, including FFP2 masks for certain materials.

Material and Design Considerations for SLS Success

SLS production success depends on smart design choices and the right material picks. Getting the best results means you need to think over both technical limits and how materials behave in the selective laser sintering process.

Designing for powder drainage and removal

Powder evacuation plays a key role in SLS design. Unsintered powder stays trapped inside hollow parts without proper escape routes. Designers need to add at least two escape holes per hollow area that measure 3.5mm in diameter. Bigger holes aid better powder removal, so multiple openings near edges or on opposite sides give you a full picture. Parts that need assembly should have a 0.5-0.6mm gap between components to avoid friction. Hollow designs cut weight and costs but need smart planning for powder removal.

Shrinkage compensation in CAD models

Thermal shrinkage creates a major challenge in SLS production. Designers usually scale up dimensions by 3-3.5% before printing to fix this issue. Simple uniform scaling doesn’t work well because shrinkage varies across the part. Better compensation methods look at every layer and hatch length instead of using one scale factor. This technique showed dimensional accuracy gains of 55-62% compared to what manufacturers suggest. Flat surfaces tend to warp easily, so adding ribs makes parts stiffer and alleviates warping.

Choosing between PA12, PA11, and TPU

Your material choice shapes how parts perform and look. PA12 (Nylon 12) comes from petroleum and resists chemicals, oils, fuels, and water really well. It handles cracks better and stays stable in cold temperatures, which makes it perfect for mechanical parts like gears. PA11, made from castor oil, gives you better impact resistance and stretches more, so it works great for hinges and snap-fit parts. When you need flexibility, TPU (Thermoplastic Polyurethane) combines rubber-like stretch with tough durability and wear resistance. Picking the right material becomes crucial to get the mechanical properties you want in specific thermal and chemical conditions.

Cost and Scalability Factors in SLS Adoption

Money plays a key role in how fast manufacturers adopt SLS technology. Companies need to understand the economics to make smart decisions about adding this powerful technology to their production lines.

Original machine investment vs long-term ROI

The cost of SLS equipment creates a major barrier for many businesses. Entry-level SLS systems cost around USD 50,000, while industrial-grade systems can cost more than USD 500,000. The market has more options available now, with benchtop industrial printers starting at just under USD 30,000. Complete ecosystems that have powder management stations cost about USD 60,000.

The high original investment pays off in the long run. The printing costs with some SLS systems are 4 to 10 times lower than what service providers charge. One case study showed that after 71 build cycles (8,520 parts), the total cost of an SLS printer and powder became cheaper than ordering parts from outside vendors.

Cost per part in low vs high volume runs

Production volume has a big impact on part costs in SLS manufacturing. Machine costs dominate in low volume production. Material costs become the biggest factor when volumes increase.

SLS can print many parts at once in batch production. This brings the cost per part down to as low as USD 7.00. A typical part costs about USD 1.41, which breaks down into material (USD 0.71), equipment cost over time (USD 0.36), and labor (USD 0.34).

The numbers show that SLS works well economically for runs up to 6,000-14,000 units, depending on the system. Assembly production has a lower threshold – one study found SLS stays economical for up to 42 units.

Comparison with FDM and SLA cost structures

Each 3D printing technology comes with its cost profile:

| Cost Factor | SLS | FDM | SLA |

|---|---|---|---|

| Material Costs | USD 50-120/kg | USD 20-50/kg | USD 100-300/liter |

| Machine Costs | USD 50,000-500,000+ | USD 200-5,000 | USD 3,000-200,000 |

| Labor Costs | USD 20-50/hour | USD 15-30/hour | USD 20-50/hour |

SLS has a unique economic advantage because it lets you reuse up to 80% of unused powder. This feature cuts down on waste and material costs over time, which helps balance out the higher upfront investment.

Conclusion

Selective laser sintering has reshaped the landscape of additive manufacturing with capabilities that leave traditional methods behind. Engineers and manufacturers can now create complex shapes without support structures, which opens up new design possibilities. SLS also produces isotropic parts that work just like injection-molded components, with strength that’s equal in all directions.

SLS technology brings its share of challenges that need careful attention. Production planning and costs take a hit from surface finish issues, limited material choices, and the need for post-processing work. Large, flat surfaces often warp while cooling, which creates problems when exact measurements matter.

Money talks when it comes to adopting SLS in manufacturing. This method works best economically for batches between 6,000-14,000 units, depending on how complex the parts are. The high startup costs become less of an issue over time since you can recycle unused materials.

Your success with SLS boils down to smart design and picking the right materials. Part quality and performance depend on creating good powder flow paths, accounting for shrinkage, and choosing the right material from options like PA12, PA11, or TPU. Companies should weigh these technical aspects along with the costs before jumping into SLS.

The technology keeps getting better as more affordable systems hit the market. Small businesses that couldn’t afford SLS before can now get their hands on this powerful manufacturing tool. SLS shines brightest when making complex, low-volume parts that would cost too much or be impossible to make with regular manufacturing methods.

Key Takeaways

Understanding the true advantages and limitations of SLS technology is crucial for making informed manufacturing decisions that impact both production quality and long-term profitability.

• SLS enables complex geometries without support structures, allowing complete design freedom for hollow spaces and intricate internal features impossible with traditional manufacturing.

• Parts exhibit 3-3.5% shrinkage during cooling and require strategic powder evacuation holes (minimum 3.5mm diameter) for successful hollow designs.

• Cost-effectiveness peaks at 6,000-14,000 unit production runs, with material recyclability (up to 80%) offsetting higher initial equipment investments of $50,000-$500,000.

• Surface roughness (5-25 μm) and 30% internal porosity limit applications requiring smooth finishes or water-tight components compared to injection molding.

• Material selection between PA12, PA11, and TPU directly impacts mechanical properties, with PA12 offering chemical resistance and PA11 providing superior impact resistance for specific applications.

The technology’s unique combination of design freedom, mechanical strength, and batch production efficiency makes it particularly valuable for complex, low-volume manufacturing where traditional methods prove technically impossible or economically unfeasible.

FAQs

Q1. What are the main advantages of Selective Laser Sintering (SLS)? SLS offers several benefits, including the ability to create complex geometries without support structures, high mechanical strength and isotropy in printed parts, efficient batch production through nesting, and the ability to reuse up to 80% of unused powder, reducing waste and costs.

Q2. What are some limitations of SLS technology? Some key limitations of SLS include shrinkage and warping during cooling, surface roughness and porosity in finished parts, limited material options (mostly nylon-based), time-consuming post-processing, and potential safety concerns when handling fine powder materials.

Q3. How does SLS compare to other 3D printing technologies in terms of cost? SLS typically has higher initial equipment costs ($50,000-$500,000+) compared to FDM or SLA. However, it can be cost-effective for production runs of 6,000-14,000 units due to its ability to nest multiple parts and recycle unused powder. Material costs for SLS fall between FDM and SLA.

Q4. What design considerations are important for successful SLS printing? Key design considerations include incorporating powder drainage holes (minimum 3.5mm diameter) for hollow parts, compensating for 3-3.5% shrinkage in CAD models, and choosing appropriate materials (PA12, PA11, or TPU) based on desired mechanical properties and application requirements.

Q5. For what types of manufacturing projects is SLS most suitable? SLS is particularly well-suited for producing complex, low-volume parts where traditional manufacturing methods are technically impossible or economically unfeasible. It excels in creating functional prototypes and end-use parts with consistent mechanical properties, making it valuable for industries requiring customized or intricate components.