Titanium seamless tubes have a strength-to-weight ratio that beats steel, aluminum, and copper. These tubes are made without welds or joints and offer exceptional structural integrity while staying lightweight. The absence of welds and joints means these tubes are less prone to leaks compared to welded versions.

These tubes work great in harsh environments because they resist corrosion well, especially when exposed to seawater and biochemical agents. Chemical processing heat exchangers often use Grade 2 titanium seamless tubes. Grade 5 versions provide even more strength for tougher applications. The tubes can handle heavy loads without becoming too bulky. This makes them perfect when you need to cut weight but can’t compromise on strength and stability. Chinese manufacturers produce about 20% of their total titanium output as pipes. This helps suppliers meet the growing needs of many industries.

No Welds, No Weak Points: Structural Integrity of Seamless Tubes

The way tubes are made plays a huge role in determining how strong a piping system will be. Seamless titanium tubes stand at the top of engineering reliability. They eliminate the biggest problem found in welded pipes – the weld seam. This vital difference changes everything from pressure ratings to how well these tubes perform in critical situations.

Stress Concentration in Welded Joints

Welded titanium pipes have a built-in design flaw: stress concentration points along the weld seam. These spots become the system’s weak link and substantially reduce what it can handle. The ASME B31.3 Process Piping Code backs this up. It rates welded tubes 15 percent lower in working pressure than similar seamless tubes. Some studies show even lower ratings, with welded tubes working at just 80 percent of what seamless tubes can handle.

Making welded titanium tubes starts with rolling titanium strips or coils into tube shapes. These are joined using high-frequency welding. This creates seams inside and out where:

- The strip and weld area don’t match up perfectly

- Small gaps form on both sides of the weld

- Weak spots develop that won’t work in critical uses

These structural issues become a real headache when tubes face dynamic forces, temperature changes, or corrosive environments. The weld area might corrode faster, and cracks can spread, which could lead to a complete rupture under pressure.

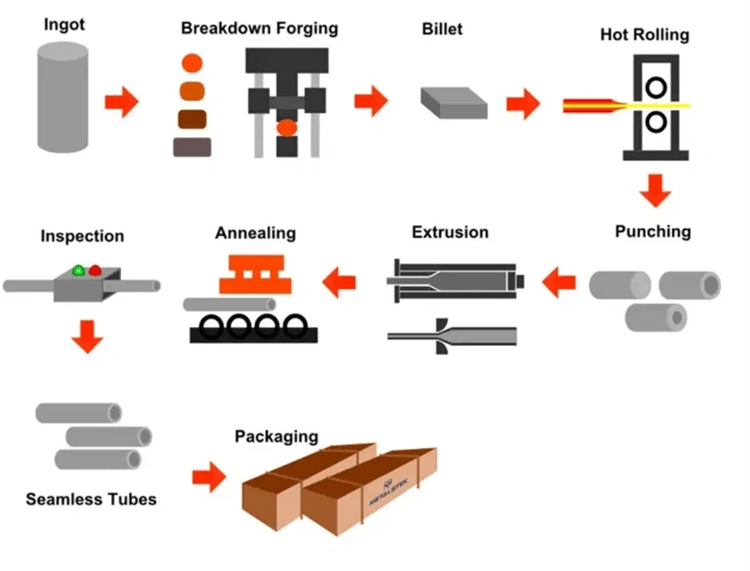

Uniform Grain Structure in Seamless Tubes

Seamless titanium tubes, on the other hand, offer excellent structural performance because they’re made as one piece. The manufacturing process heats and extrudes solid titanium billets to create a solid structure with no joints. This gives several advantages in terms of metal properties:

The inside of properly made seamless titanium tubes shows tiny primary alpha grains stretched along the tube’s length. This grain pattern adds to the tube’s strength. The structure keeps some of this helpful directional quality even after heat treatment.

Hot extrusion’s high temperatures and shaping lead to an even, refined grain structure throughout. This means strength, yield point, and flexibility stay consistent across the whole tube.

These tubes also have smoother insides than welded ones. This helps liquids flow better and cuts down on buildup inside the tube. These benefits matter a lot in chemical processing, high-pressure hydraulic systems, or marine environments.

With no stress concentration points, seamless titanium tubes work great when you need:

- Higher pressure handling

- Better resistance to bending and impacts

- More reliability when parts get tired

- Improved performance with temperature changes

The solid structure of seamless titanium tubes makes them the smart choice when failure isn’t an option.

Superior Corrosion Resistance in Harsh Environments

Titanium seamless tubes stand out because of their strong resistance to corrosion in industrial use. These tubes work so well in harsh environments thanks to titanium’s chemical makeup and the fact that they don’t have weak spots you’d typically find in welded tubes.

Oxide Layer Formation in Grade 2 Titanium

Titanium seamless tubes resist corrosion because they form a stable oxide film on their surface. When heated to high temperatures, titanium alloys create a protective barrier that shields the base metal from corrosive materials. This natural oxide layer works better than stainless steel and holds up well where pitting and crevice corrosion are common.

Grade 2 titanium, which manufacturers often use for seamless tubes, creates an effective oxide layer. The metal changes between 600°C and 1200°C to form rutile (TiO2). This happens in two steps:

- The oxide layer grows in a straight line with an activation energy of 53 kJ/mol

- After that, it grows in a curve with an activation energy of 155 kJ/mol

Temperature affects how thick and good this oxide layer becomes. Tests show that heating and cooling at 600°C creates oxide layers 1.26 μm thick (4 cycles) and 2.12 μm thick (12 cycles). At 700°C, the layers get much thicker – 5.17 μm and 9.45 μm.

Titanium handles oxidizing substances well, but it struggles with reducing acids that can break down its protective oxide film. Despite that, adding heavy metal salts helps prevent corrosion in these situations.

Seamless Tubes in Marine and Chemical Applications

Seamless titanium tubes work even better against corrosion because they have a uniform structure. They don’t have welded joints that could create weak spots or stress points, so the protection stays consistent across the whole surface, which matters in tough environments.

Grade 2 titanium seamless tubes show amazing corrosion resistance in marine environments:

- They never crack from stress in seawater

- They resist crevice corrosion below 80°C, whatever the pH level

- They handle flowing seawater well, even at speeds up to 40 m/sec

- Nothing happens to them from any kind of microbiological corrosion

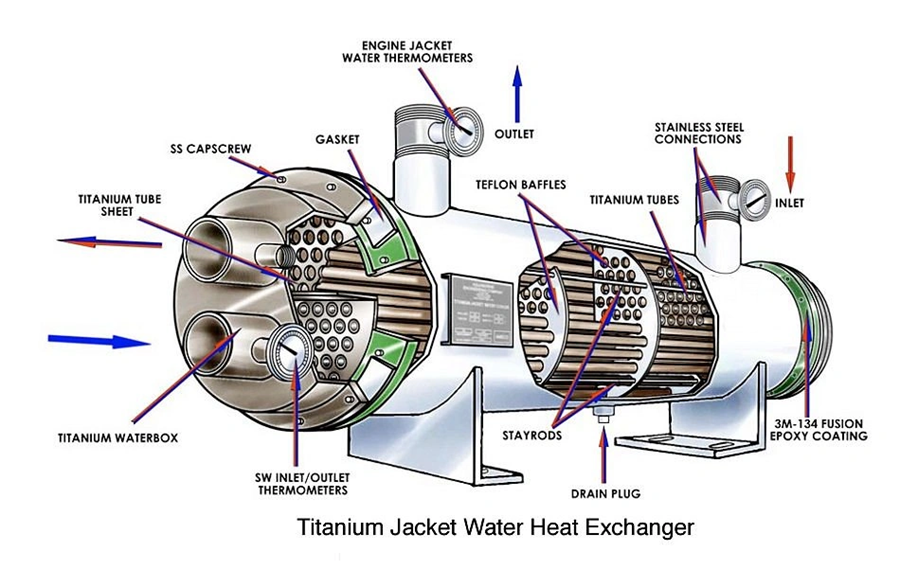

These features make seamless titanium tubes perfect for seawater-cooled heat exchangers, pressure vessel piping, and marine equipment. Titanium keeps its strength in seawater just as well as in air, with similar fatigue limits and crack growth rates in both environments.

These tubes work just as impressively in chemical processing. They don’t pit, crack, or corrode under stress, which makes them perfect for handling harsh chemicals in manufacturing. Grade 2 titanium seamless tubes work especially well with:

- Seawater and brines

- Inorganic salts

- Moist chlorine gas

- Oxidizing acids

- Organic compounds and acids

Then, suppliers have created special products for industries where regular materials would break down faster. Grade 7 titanium (with 0.15% palladium) and Grade 12 titanium (with 0.3% Mo and 0.8% Ni) seamless tubes give even better protection in the toughest chemical processing environments.

The natural corrosion resistance from oxide formation and the lack of vulnerable welded joints make titanium seamless tubes the best engineering solution for harsh environments where material strength matters.

Weight-to-Strength Ratio: Why Seamless Titanium Wins

Engineers choose titanium seamless tubes because of their amazing weight-to-strength ratio. This quality is vital in applications where materials need to perform at their best while staying lightweight. The benefits become even more obvious when you compare seamless tubes with welded ones in different materials.

Comparison with Welded Steel and Copper Pipes

Titanium seamless tubes work better in structural applications and outperform traditional materials by a lot. The strength-to-weight ratio of titanium beats steel, aluminum, and copper. This creates real advantages in many industries:

- Reduced mass with equivalent strength: Titanium weighs 45% less than similar steel tube alloys but stays just as strong

- Better load capacity: Seamless titanium pipes can hold heavy weights without getting too bulky

- Lower installation costs: The high strength-to-weight ratio cuts down transportation and installation expenses while needing less support

Seamless titanium tubes work even better because they don’t have welds. They spread forces evenly throughout their structure, unlike welded pipes. Welded titanium pipes can’t match what seamless ones can do in high-stress applications, even though they’re made from the same material.

This difference matters a lot in marine environments, aerospace systems, and chemical processing. Suppliers of titanium seamless tubes often point this out when selling to critical infrastructure projects where weight reduction and reliability can’t be compromised.

Grade 5 Titanium Seamless Tube Performance Metrics

Grade 5 titanium (Ti-6Al-4V) seamless tubes are the best-performing titanium alloys out there. They make up more than 50% of all titanium used worldwide. These tubes show impressive numbers that explain why they’re so popular in high-performance uses:

The tensile strength goes from 895 to 1000 MPa, which beats many steel alloys while weighing less. Yield strength stays between 828 to 924 MPa, so the tubes keep their shape even under heavy loads. This makes them perfect when you need precise measurements under stress.

Grade 5 titanium tubes shine when it comes to fatigue resistance. Their endurance limit reaches about 50% of their ultimate tensile strength. That’s why you see them so much in aerospace parts and high-performance mechanical systems.

These tubes work great in temperatures from -210°C to 400°C. You can use them in all kinds of extreme conditions. Yes, it is this mix of being lightweight and handling temperature changes that makes seamless titanium tubes perfect for heat exchangers and pressure-critical systems.

Thermal and Pressure Tolerance in Seamless Tubes

Titanium seamless tubes are crucial for industries with extreme operating conditions because of their exceptional heat resistance and pressure handling abilities. These outstanding properties come from titanium’s unique molecular structure and the precision that goes into seamless manufacturing.

High Melting Point of Titanium Alloys

Titanium’s resistance to heat stress starts with its incredibly high melting point. Pure titanium melts at around 1725°C (3135°F), which is a big deal as it means that it outperforms common industrial metals. Grade 5 titanium (Ti-6Al-4V) seamless tubes show impressive thermal stability with melting points ranging from 1878°C to 1933°C. This makes them reliable performers in high-temperature environments.

These tubes work well across a wide temperature range. CP Grade 2 titanium tubes perform reliably up to 425°C. Grade 5 titanium seamless tubes stay structurally sound at temperatures up to 427°C (800°F). Their remarkable heat resistance makes them perfect for chemical processing plants, refineries, and high-pressure steam systems.

The tubes develop a protective oxide layer at high temperatures that boosts their heat resistance. This oxide forms in a specific way as titanium changes into rutile (TiO₂), which adds more protection against heat damage.

Pressure Ratings in Heat Exchanger Systems

Titanium seamless tubes handle pressure better than welded ones because they have uniform strength throughout their structure with no weak points. Manufacturers create these tubes with specific pressure ratings based on size:

- 1/4″ diameter tubes with 0.035″ wall thickness withstand pressures up to 4,800 psig

- 3/8″ diameter tubes with 0.065″ wall thickness handle 6,100 psig

- 1″ diameter tubes with 0.120″ wall thickness tolerate 4,300 psig

Grade 5 titanium seamless tubes shine in ultra-high-pressure applications. This explains why they’re common in natural gas processing, where pressures often go above 5,000 psi. Heat exchanger systems benefit from titanium’s mix of heat stability and pressure resistance. The tubes keep performing well through temperature changes from -196°C to 600°C.

Suppliers often point out how these tubes can handle tough conditions in heat exchangers, condensers, and high-pressure hydraulic systems. Their superior resistance to temperature cycling and pressure creates an engineering solution that lasts longer than standard materials in harsh environments.

Ease of Fabrication and Long-Term Cost Efficiency

Titanium seamless tubes are more than just another material choice – they’re a smart business investment. The upfront costs might be higher than other options, but the long-term financial rewards make up for this premium through longer service life and less maintenance.

Reduced Maintenance in Seamless Systems

Seamless titanium tubing systems prove extremely durable and last 20-40 years. These systems last longer because they don’t have welds that could crack or need fixing. Titanium’s complete corrosion resistance means engineers can design thinner-walled tubing that performs well and costs less.

The cost benefits become clear when you look at titanium’s entire life cycle instead of just the purchase price. Companies that use titanium seamless tubes spend much less money over time compared to those using standard materials. More facilities now choose seamless titanium despite higher upfront costs. They know its durability, reliability, and low maintenance needs create real value as time goes on.

Weld Inspection and Repair Costs in Welded Pipes

Welded titanium pipes require strict inspection, which adds significant costs throughout their life. The usual procedures include:

- Ultrasonic testing to find internal defects

- Penetrant testing to spot surface cracks and flaws

- Radiographic examinations to check weld quality

Each welded joint needs detailed documentation that covers joint ID, base material type, filler metal details, fit-up records, and inspection results. Repairs on welded sections require extra testing and certification, which creates ongoing maintenance work that seamless systems don’t need.

The inspection tools themselves cost a lot of money. Traditional X-ray film methods require supplies, processing chemicals, and storage space. Modern inspection systems need special equipment that costs thousands of dollars. These continuing expenses make welded titanium pipe systems much more expensive to own and operate.

Availability from Seamless Titanium Tube Suppliers

Today’s seamless titanium tube suppliers offer many product options in different grades and sizes. Titanium Processing Center keeps large stocks of both seamless and welded tubes in various specifications. Other suppliers stock pure titanium (grades 1-4) and alloy versions with aluminum and vanadium.

The titanium industry has plenty of extra production capacity to ensure materials are ready for new uses without supply issues. This manufacturing strength enables seamless titanium tube suppliers to meet the special requirements of the petroleum, chemical processing, marine, and aerospace industries quickly.

Conclusion

Titanium seamless tubes are the ultimate engineering solution when performance is critical. These tubes solve a big problem – they eliminate the weak point that all welded pipes share: the weld seam. This design provides unmatched structural integrity throughout their lifespan. The tubes’ uniform composition and grain structure ensure consistent mechanical properties, making them substantially more reliable under pressure, heat cycling, and dynamic forces.

On top of that, these tubes excel at resisting corrosion thanks to their protective oxide layer, especially in Grade 2 and Grade 5 variants. This natural barrier protects the base metal from harsh substances, which makes these tubes perfect for marine environments, chemical processing plants, and other tough conditions where regular materials would deteriorate faster.

The tubes’ impressive strength-to-weight ratio sets them apart from other options. Grade 5 titanium tubes deliver tensile strength between 895 and 1000 MPa while weighing 45% less than similar steel alloys. This lighter weight means lower installation costs, reduced structural support needs, and better system efficiency overall.

These tubes offer vital thermal stability benefits, too. They maintain their structural integrity at temperatures up to 427°C while handling pressures over 5,000 psi in certain setups. This combination makes them perfect for heat exchangers, condensers, and high-pressure hydraulic systems in extreme conditions.

The original cost might be higher, but titanium seamless tubes are budget-friendly in the long run. They last longer, need minimal maintenance, and don’t require expensive weld inspections. Most systems using these tubes work reliably for 20-40 years without the ongoing costs you’d see with welded alternatives.

Engineers choose titanium seamless tubes over welded pipes because failure isn’t an option in critical applications. The seamless construction creates superior components that outperform welded alternatives in virtually every important performance metric for industrial applications.

Key Takeaways

Understanding the engineering advantages of titanium seamless tubes reveals why they consistently outperform welded alternatives in critical industrial applications.

• Seamless tubes eliminate weld seams, providing 15-20% higher pressure ratings and superior structural integrity without stress concentration points.

• Titanium’s protective oxide layer delivers exceptional corrosion resistance, enabling 20-40 year service life in harsh marine and chemical environments.

• Grade 5 titanium seamless tubes offer 895-1000 MPa tensile strength while being 45% lighter than steel, optimizing weight-to-strength performance.

• These tubes withstand temperatures up to 427°C and pressures exceeding 5,000 psi, making them ideal for extreme operating conditions.

• Despite higher upfront costs, seamless tubes eliminate expensive weld inspections and repairs, delivering superior long-term cost efficiency.

The absence of welded joints fundamentally transforms performance capabilities, making seamless titanium tubes the definitive choice for applications where material failure is not an option.

FAQs

Q1. What are the main advantages of titanium seamless tubes over welded pipes? Titanium seamless tubes offer superior structural integrity, higher pressure ratings, and better corrosion resistance compared to welded pipes. They eliminate weak points at weld seams, provide uniform strength throughout, and can withstand harsh environments for 20-40 years without significant maintenance.

Q2. How do titanium seamless tubes perform in high-pressure and high-temperature conditions? Titanium seamless tubes excel in extreme conditions, maintaining structural integrity at temperatures up to 427°C (800°F) and pressures exceeding 5,000 psi in certain configurations. This makes them ideal for heat exchangers, chemical processing facilities, and high-pressure hydraulic systems.

Q3. Are titanium seamless tubes cost-effective despite their higher initial price? Yes, titanium seamless tubes offer long-term cost efficiency. While the upfront cost is higher, they provide extended service life, minimal maintenance requirements, and eliminate expensive weld inspection and repair costs associated with welded pipes, resulting in lower total ownership costs over time.

Q4. How does the strength-to-weight ratio of titanium seamless tubes compare to other materials? Titanium seamless tubes, particularly Grade 5 (Ti-6Al-4V), offer an exceptional strength-to-weight ratio. They provide tensile strength ranging from 895 to 1000 MPa while being 45% lighter than comparable steel alloys, making them ideal for applications requiring high strength and low weight.

Q5. What industries benefit most from using titanium seamless tubes? Industries that benefit most from titanium seamless tubes include aerospace, marine engineering, chemical processing, oil and gas, and power generation. These sectors value the tubes’ corrosion resistance, high strength-to-weight ratio, and ability to withstand extreme temperatures and pressures in critical applications.