Ti-6Al-4V, also known as Grade 5, stands out as the premier Titanium Alloy Grade for 3D printing.

- Engineers value its exceptional strength-to-weight ratio and impressive corrosion resistance.

- Manufacturers rely on its compatibility with advanced additive manufacturing systems.

Grade 5 sets the benchmark for high-performance parts in aerospace, medical, and industrial applications.

Key Takeaways

- Ti-6Al-4V (Grade 5) is the best titanium alloy for 3D printing due to its high strength, corrosion resistance, and good printability.

- This alloy suits many industries like aerospace, medical, automotive, and marine because it makes strong, lightweight, and durable parts.

- Different 3D printing methods like SLM, EBM, and DED work well with Grade 5, each offering unique benefits and requiring proper post-processing.

- Choosing the right titanium grade depends on the application’s needs, including strength, ductility, corrosion resistance, and cost.

- Following standards and certifications ensures safe, reliable parts, especially for critical uses like medical implants and aerospace components.

Why Ti-6Al-4V (Grade 5) Is the Leading Titanium Alloy Grade

Key Properties of Ti-6Al-4V (Grade 5)

Ti-6Al-4V (Grade 5) delivers a unique combination of mechanical strength, ductility, and corrosion resistance, making it the most popular Titanium Alloy Grade for additive manufacturing. Its mechanical properties, especially when produced by 3D printing, are impressive and well-documented:

| Property | Printed in Z-direction | Printed in X/Y-direction |

|---|---|---|

| Tensile Strength | 1070 MPa | 1070 MPa |

| Yield Strength | 1020 MPa | 1000 MPa |

| Elongation | 14 % | 13 % |

These values reflect the typical performance of 3D-printed Ti-6Al-4V after stress relief at 800°C. The alloy consistently achieves tensile strengths above 1000 MPa and maintains elongation values suitable for demanding engineering applications.

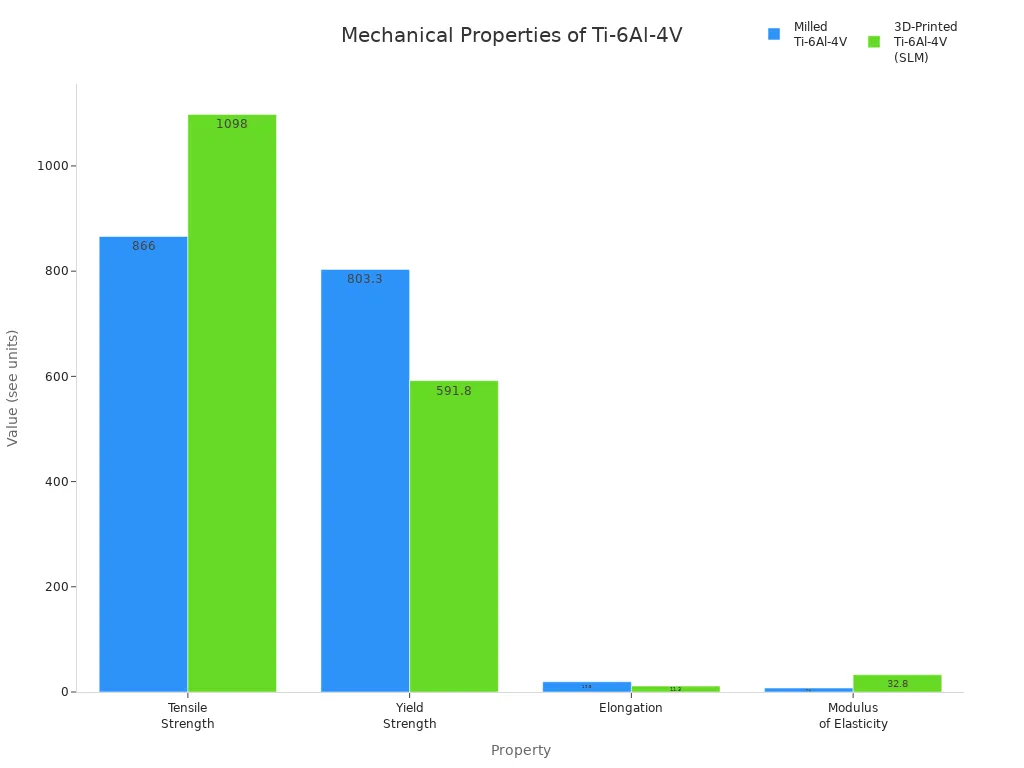

Comparing milled and 3D-printed samples, selective laser melting (SLM) technology can yield up to 26% higher tensile strength, though with slightly reduced elongation. The following chart visually compares key mechanical properties:

Corrosion resistance is another critical property. Microstructural studies show that the martensitic α’ phase formed during additive manufacturing creates a more uniform and protective titanium oxide film. Post-processing, such as heat treatment or ultrasonic shot peening, further enhances corrosion resistance, making the alloy suitable for harsh environments.

Advantages for 3D Printing Applications

Ti-6Al-4V (Grade 5) offers several advantages that set it apart from other Titanium Alloy Grades in additive manufacturing:

- High strength-to-weight ratio enables lightweight yet robust parts, ideal for aerospace and automotive sectors.

- Excellent corrosion resistance ensures durability in marine, chemical, and biomedical environments.

- High temperature resistance allows use in turbine blades and combustion chambers.

- Good biocompatibility supports medical and dental implants.

- Manufacturing flexibility enables the creation of complex geometries, such as lattice structures and internal cooling channels.

- Mature and widely used alloy status provides a wealth of data, established supply chains, and proven performance across industries.

| Advantage/Feature | Description |

|---|---|

| High strength-to-weight ratio | Exceptional tensile strength (>1000 MPa) with low density. |

| Excellent corrosion resistance | Maintains properties in seawater and chemicals. |

| High temperature resistance | Suitable for high-heat components. |

| Good biocompatibility | Safe for biomedical use. |

| Manufacturing flexibility | Supports complex 3D-printed designs. |

| Mature and widely used alloy | Outperforms other Titanium Alloy Grades in strength and design freedom. |

Additive manufacturing processes such as electron beam melting (EBM), selective laser melting (SLM), and directed energy deposition (DED) all support Ti-6Al-4V. These methods allow for rapid prototyping and cost-effective production. Post-processing steps like annealing, hot isostatic pressing, and machining further improve fatigue life and surface finish, ensuring that printed parts meet strict industry standards.

Note: Surface finish and fatigue performance depend on the chosen 3D printing process and post-processing. Machining and polishing can significantly enhance the durability of as-built parts.

Typical Use Cases

Ti-6Al-4V (Grade 5) finds application across a wide range of industries due to its balanced properties and printability:

- Aerospace: Airframe components, engine parts, landing gear, and turbine blades benefit from the alloy’s strength, thermal stability, and weight reduction.

- Medical: Orthopedic and dental implants, prosthetics, and surgical instruments leverage its biocompatibility and ability to support porous, osseointegrative structures.

- Automotive and Motorsports: Performance parts such as brake calipers, connecting rods, and exhaust systems use the alloy for weight savings and durability.

- Energy: Turbine components and power generation equipment require the alloy’s strength and corrosion resistance.

- Sports and Recreation: High-performance bicycle frames, golf club heads, and tennis rackets utilize the alloy for lightweight strength.

- Marine and Chemical Processing: Heat exchangers, piping, and subsea systems rely on the alloy’s resistance to corrosion.

- Industrial: Valves, fittings, and chemical processing equipment benefit from the alloy’s mechanical and chemical stability.

Case studies highlight the versatility of this Titanium Alloy Grade. For example, multilayer materials produced with xBeam 3D printing combine Ti-6Al-4V with ceramic reinforcements for advanced ballistic protection. In another study, selective laser melting followed by laser remelting improved both tensile strength and corrosion resistance, demonstrating the alloy’s adaptability to high-performance requirements.

Comparing Titanium Alloy Grades for 3D Printing

Ti-6Al-4V (Grade 5) vs. Ti-6Al-4V ELI (Grade 23)

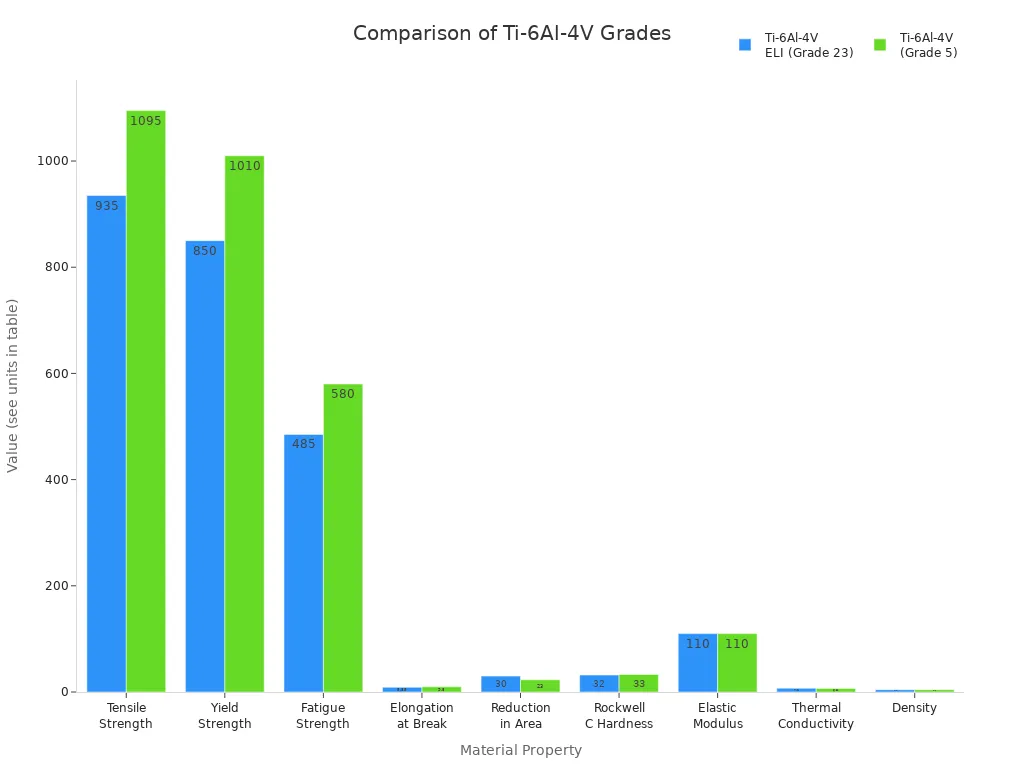

Engineers often compare Ti-6Al-4V (Grade 5) and Ti-6Al-4V ELI (Grade 23) when selecting a Titanium Alloy Grade for additive manufacturing. Both alloys share a similar base composition, but Grade 23 contains significantly lower levels of interstitial elements such as oxygen, nitrogen, and hydrogen. This reduction enhances ductility, formability, and impact resistance. Grade 23 also includes palladium, which improves corrosion resistance and biocompatibility, making it ideal for medical implants.

| Property | Ti-6Al-4V ELI (Grade 23) | Ti-6Al-4V (Grade 5) |

|---|---|---|

| Tensile Strength (MPa) | 930 to 940 | 1000 to 1190 |

| Yield Strength (MPa) | 850 to 870 | 910 to 1110 |

| Fatigue Strength (MPa) | 470 to 500 | 530 to 630 |

| Elongation at Break (%) | 6.7 to 11 | 8.6 to 11 |

| Reduction in Area (%) | 30 | 21 to 25 |

| Rockwell C Hardness | 32 | 33 |

| Elastic Modulus (GPa) | 110 | 110 |

| Thermal Conductivity (W/m-K) | 7.1 | 6.8 |

| Density (g/cm³) | 4.4 | 4.4 |

Grade 5 provides higher tensile and yield strengths, which suit aerospace and structural applications. Grade 23, with its improved ductility and toughness, excels in medical and demanding aerospace parts where biocompatibility and reliability are critical. Lower interstitials in Grade 23 also reduce residual stresses and distortion during 3D printing, resulting in more reliable parts.

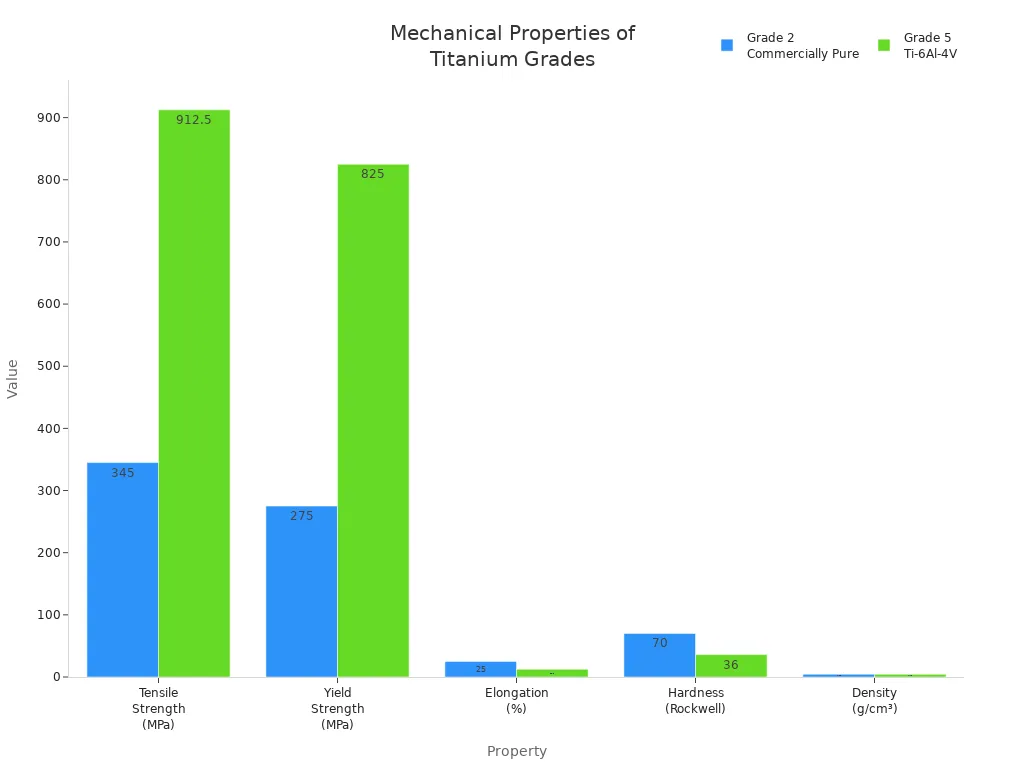

Commercially Pure Titanium Alloy Grades (Grade 1, Grade 2)

Commercially pure titanium grades, such as Grade 1 and Grade 2, offer excellent corrosion resistance and biocompatibility. These grades contain minimal alloying elements, resulting in lower strength but higher ductility compared to alloyed grades.

| Property | Grade 2 (CP Titanium) | Grade 5 (Ti-6Al-4V) |

|---|---|---|

| Tensile Strength | ~345 MPa | ~895 – 930 MPa |

| Yield Strength | ~275 MPa | ~825 MPa |

| Elongation | 20% – 30% | 10% – 15% |

| Hardness | Rockwell B 70 | Rockwell C 36 |

| Corrosion Resistance | Excellent | Very good |

| Weldability | Excellent | Good |

| Machinability | Good | Difficult |

| Density | 4.51 g/cm³ | 4.43 g/cm³ |

Grade 1, the purest Titanium Alloy Grade, offers the best ductility and corrosion resistance, making it suitable for heat exchangers, marine components, and medical implants. Grade 2 balances strength and formability, often used in aircraft components and chemical processing equipment. These grades are easier to weld and machine, but their lower strength limits their use in high-performance applications.

Other Titanium Alloy Grades in Additive Manufacturing

Several alternative titanium alloys serve specialized roles in additive manufacturing. Ti-3Al-2.5V (Grade 9) provides moderate strength and excellent weldability, making it popular for hydraulic tubing and sports equipment. Ti-6Al-2Sn-4Zr-2Mo offers enhanced high-temperature strength and oxidation resistance, which benefits jet engine and turbine blade production. Beta titanium alloys deliver high strength and improved ductility, supporting fasteners and landing gear.

| Titanium Alloy Grade | Unique Properties | Typical Applications |

|---|---|---|

| Ti-6Al-4V (Grade 5) | High strength, toughness, corrosion resistance, fatigue resistance, biocompatibility | Aircraft frames, medical implants, racing components |

| Ti-3Al-2.5V (Grade 9) | Highly formable, moderate strength, seawater resistance | Hydraulic tubing, marine, sports equipment |

| Ti-6Al-2Sn-4Zr-2Mo | High-temperature strength, oxidation resistance | Jet engines, turbine blades, aerospace structures |

| Beta Titanium Alloys | High strength, excellent cold formability, improved ductility | Fasteners, landing gear, sporting goods |

| Pure Titanium (Grades 1-4) | Superior biocompatibility, corrosion resistance | Chemical processing, medical implants, desalination |

Each Titanium Alloy Grade brings unique advantages, but Ti-6Al-4V remains the industry benchmark due to its balance of strength, processability, and extensive qualification data.

Titanium Alloy Grade Performance in 3D Printing Technologies

Powder Bed Fusion (SLM, DMLS)

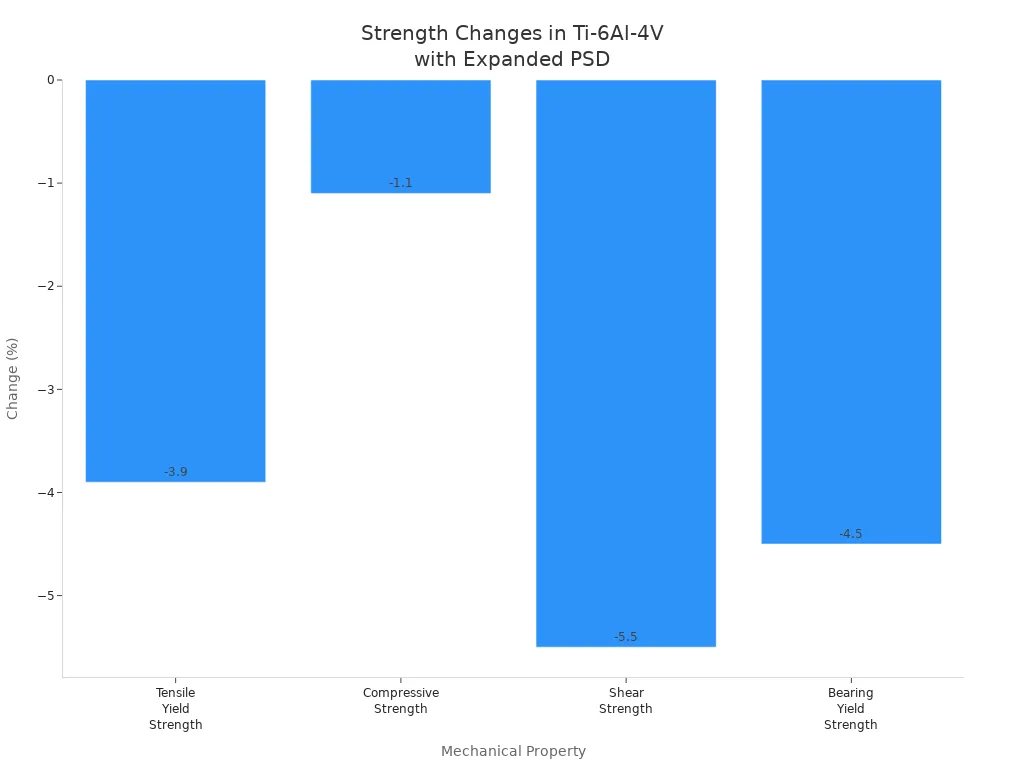

Ti-6Al-4V (Grade 5) demonstrates excellent compatibility with powder bed fusion technologies, including selective laser melting (SLM) and direct metal laser sintering (DMLS). These methods, both part of laser powder bed fusion (LPBF), allow manufacturers to produce high-precision components for aerospace and medical applications. Studies show that even when using powders with a wider particle size distribution, the mechanical properties of Ti-6Al-4V remain within industry standards. For example, tensile yield strength decreases by only 3.9%, and compressive strength drops by 1.1%. These minor reductions do not compromise the alloy’s suitability for demanding applications.

| Mechanical Property | Change with Expanded PSD (15–75 μm) | Notes on Typical Values and Standards Met |

|---|---|---|

| Tensile Yield Strength | Decreased by 3.9% | Meets MMPDS standards despite minor reduction |

| Compressive Strength | Decreased by 1.1% | Consistent with high-performance requirements |

| Shear Strength | Decreased by 5.5% | Slight reduction attributed to microstructural changes |

| Bearing Yield Strength | Decreased by 4.5% | Within acceptable limits for aerospace applications |

| Elongation | Slight increase | Improved ductility linked to oxygen content and grain size |

The alloy’s high strength, corrosion resistance, and performance at elevated temperatures make it a preferred Titanium Alloy Grade for powder bed fusion.

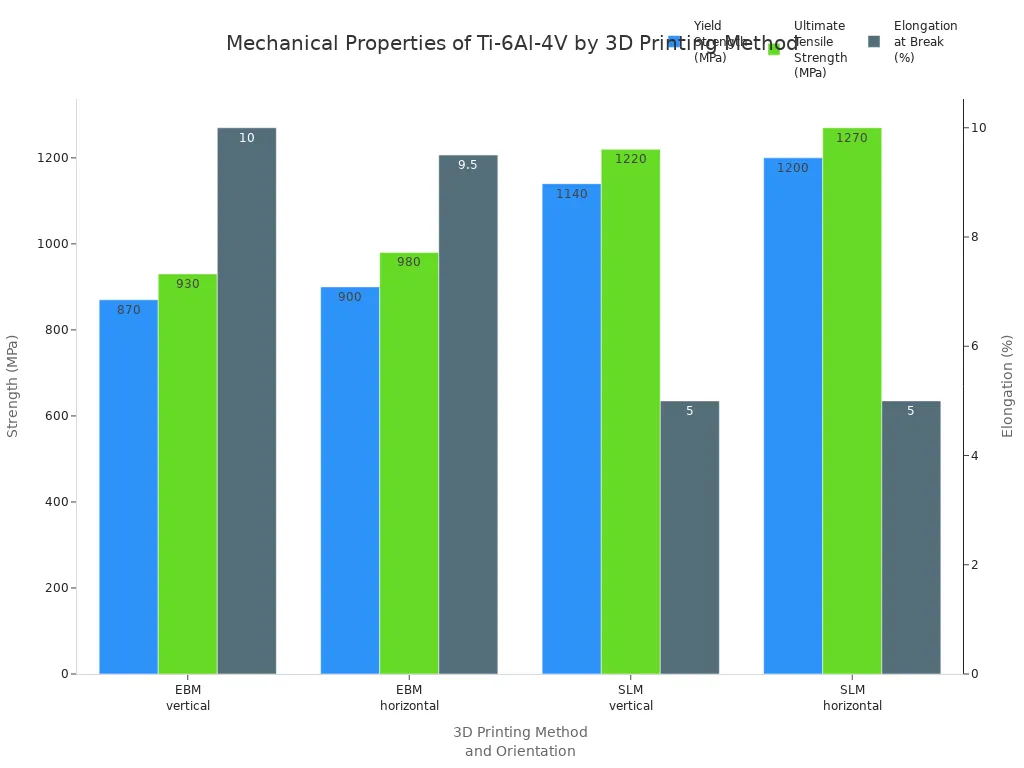

Electron Beam Melting (EBM)

Electron Beam Melting (EBM) produces Ti-6Al-4V parts with a stable α + β microstructure. This structure results in higher yield strength and uniform elongation compared to SLM, which forms a martensitic structure with higher tensile strength but lower ductility. EBM parts also show improved corrosion resistance in simulated body fluids, making them suitable for biomedical implants. However, EBM-printed parts often have higher surface irregularities, which can affect fatigue life and require additional post-processing.

| 3D Printing Technology | Recommended Ti-6Al-4V Powder | Advantages | Limitations |

|---|---|---|---|

| Electron Beam Melting (EBM) | Plasma-atomized powder (45-105µm) | Low residual stress in parts, spherical morphology improves flowability and printability | Limited material availability, higher surface irregularities compared to SLM |

Tip: EBM offers low residual stress and excellent mechanical properties, but surface finish and size limitations may require careful consideration for critical applications.

Directed Energy Deposition (DED)

Directed Energy Deposition (DED) uses Ti-6Al-4V for large, complex, and high-performance components. The process relies on precise control of laser power, scanning speed, and powder feed rate to achieve optimal microstructure and mechanical properties. DED-printed Ti-6Al-4V parts typically have slightly lower tensile strength than those produced by powder bed fusion, but they offer superior thermal stability at temperatures up to 800°C. The alloy’s chemical composition ensures stability during rapid cooling, and its fine, uniform grains enhance fatigue resistance. Challenges include powder contamination, porosity, and hydrogen-induced defects, which require strict process control.

| Method | Yield Strength (MPa) | Ultimate Tensile Strength (MPa) | Elongation at Break (%) |

|---|---|---|---|

| EBM (vertical) | ~870 | ~930 | ~10 |

| SLM (vertical) | ~1140 | ~1220 | ~5 |

| EBM (horizontal) | ~900 | ~980 | ~9.5 |

| SLM (horizontal) | ~1200 | ~1270 | ~5 |

DED remains a strong choice for producing large-scale parts where a balance of strength, ductility, and thermal stability is required.

Choosing the Right Titanium Alloy Grade by Application

Aerospace and Defense Applications

Aerospace and defense sectors demand materials that perform under extreme conditions. Engineers select Titanium Alloy Grades based on specific requirements:

- High specific strength

- High thermal strength

- Good low-temperature performance

- Strong corrosion resistance

Titanium alloys must also withstand ultra-high and ultra-low temperatures, high vacuum, and corrosive environments. The quality of titanium alloy powder, including particle size and purity, directly impacts the final component’s reliability. Additive manufacturing enables design flexibility and significant weight reduction, which are critical for aerospace structures and propulsion systems.

| Aerospace Application | Performance Feature | Relevant Standards |

|---|---|---|

| Airframe Components | High strength, lightweight | AMS 4911 |

| Engine Components | Maintains strength at elevated temperatures | AMS 4911, AMS 4928 |

| Fasteners and Structural | Strength-to-weight ratio, durability | AMS 4928 |

| Military Aerospace | Reliability under stress and heat | MILT 9046 & 9047 |

Ti-6Al-4V (Grade 5) remains the workhorse Titanium Alloy Grade in this field. It offers a balance of strength, corrosion resistance, and heat tolerance. Manufacturers use it in jet engines, airframes, landing gear, and fasteners. Its consistent performance supports next-generation aerospace platforms, including supersonic aircraft and UAVs.

Medical and Dental Applications

Medical and dental industries require Titanium Alloy Grades that ensure patient safety and long-term reliability. Ti-6Al-4V (Grade 5) and its ELI variant are widely used for implants and prosthetics due to their biocompatibility, strength, and corrosion resistance. However, the bioinert surface of titanium can limit biological response, so surface modifications—such as coatings or micro-porosity—are often applied to enhance osseointegration.

Regulatory standards, including ISO 10993 and FDA guidance, require both the alloy and the validated 3D printing process to meet strict biocompatibility criteria. The final implant’s safety depends on chemical composition, printing parameters, and post-processing steps like sterilization and surface finishing. Only when all these factors align can a Titanium Alloy Grade be considered suitable for permanent medical use.

Tip: The Extra Low Interstitial (ELI) variant of Ti-6Al-4V provides improved ductility and fracture toughness, making it ideal for demanding medical applications.

Industrial and Automotive Applications

Industrial and automotive sectors value Titanium Alloy Grades for their mechanical strength, corrosion resistance, and ductility. Ti-6Al-4V (Grade 5) is the most common choice for high-performance parts such as suspension components, exhaust systems, and marine equipment. Additive manufacturing allows for topology optimization, reducing weight and material waste. This process can lower the buy-to-fly ratio from 25:1 to as low as 3:1, making production more efficient.

| Property | Grade 5 (Ti-6Al-4V) | Grade 23 (Ti-6Al-4V ELI) |

|---|---|---|

| Strength | Higher | Slightly Lower |

| Ductility | Lower | Higher |

| Corrosion Resistance | High | Slightly Higher |

| Applications | Aerospace, automotive, marine, chemical, sports equipment | Medical, dental, cryogenic |

| Cost | Generally Lower | Generally Higher |

Grade 5 titanium offers higher tensile and shear strength than alternatives like Grade 9, making it suitable for demanding environments. Grade 9, with better formability, is chosen when manufacturing efficiency and cost are priorities.

Practical Considerations for Selecting a Titanium Alloy Grade

Mechanical Properties and Performance Requirements

Selecting the right Titanium Alloy Grade for 3D printing starts with understanding the mechanical properties needed for the application. Engineers prioritize several key characteristics:

- High strength-to-weight ratio supports lightweight yet durable parts.

- Excellent corrosion resistance ensures longevity in harsh environments.

- Biocompatibility is essential for medical implants and devices.

- Fatigue resistance and toughness help parts withstand repeated stress.

- High-temperature performance maintains stability under heat.

- Particle size distribution of the powder affects both printability and final part quality.

- Weldability and fracture toughness may be critical for certain designs.

Ti-6Al-4V (Grade 5) and its ELI variant (Grade 23) meet these requirements for aerospace, medical, and automotive sectors. Their natural oxide layer protects against corrosion, while their mechanical integrity remains strong at elevated temperatures.

Cost, Availability, and Supply Chain Factors

Cost and supply chain stability play a major role in material selection. Titanium Alloy Grade 5, widely used in aerospace and medical fields, commands a higher price due to its specialized applications and complex supply chain. Commercially pure grades, such as Grade 1 and Grade 2, offer lower costs and greater availability but provide less strength.

| Titanium Grade/Type | Cost Range (per pound) | Availability | Supply Chain Stability Factors |

|---|---|---|---|

| Commercially Pure Titanium (Grades 1 & 2) | $6 – $10 | Widely available, lower strength | Stable supply, lower demand intensity |

| Titanium 6-4 Alloy (Grade 5) | $15 – $30 | Specialized applications | Higher cost, complex supply chain, affected by geopolitical factors |

| Titanium Scrap | $2 – $6 | Cost-effective recycled material | Recycling improves stability, but purity varies |

Recycling titanium scrap helps stabilize prices and supply. Additive manufacturing reduces waste and improves material efficiency. However, geopolitical tensions and export restrictions from major producers can cause price fluctuations. Manufacturers often work with certified suppliers and plan long-term procurement to reduce risks.

Certification, Standards, and Regulatory Compliance

Critical industries require strict adherence to certification and regulatory standards when using any Titanium Alloy Grade. Compliance involves several steps:

- Follow industry-specific standards for aerospace, medical, and automotive sectors.

- Use approved materials and validate properties through mechanical, chemical, and microstructural testing.

- Control printing parameters and validate post-processing steps.

- Ensure equipment and personnel meet certification requirements.

- Maintain detailed documentation for audits and regulatory reviews.

- Engage with regulatory bodies early for guidance and pre-market approvals.

- Use third-party testing and certification to verify compliance.

- Conduct prototyping and rigorous testing before full-scale production.

For aerospace, standards like ISO/ASTM 52941 and ASTM F3302 govern powder bed fusion processes and finished part properties. Medical applications require compliance with national and international standards for material quality, biocompatibility, and sterilization. Quality assurance programs and traceability support ongoing compliance and product safety.

Ti-6Al-4V (Grade 5) continues to lead as the preferred Titanium Alloy Grade for most 3D printing projects, balancing strength, durability, and versatility. Experts advise matching the alloy grade and printing technology to each application for optimal results. The table below summarizes these recommendations:

| Titanium Alloy Grade | Recommended 3D Printing Application/Technology | Key Properties and Uses |

|---|---|---|

| Ti-6Al-4V (TC4) | SLM, general additive manufacturing | High strength, toughness, fatigue resistance |

| Ti-6Al-4V ELI | Medical implants, cryogenic | Improved ductility, biocompatibility |

| CP Titanium (Grades 1 & 2) | Corrosion-resistant, marine, chemical | Excellent corrosion resistance, ductility |

Material experts and suppliers help ensure the right Titanium Alloy Grade and process for every project.

FAQ

What makes Ti-6Al-4V (Grade 5) the top choice for 3D printing?

Ti-6Al-4V (Grade 5) offers high strength, corrosion resistance, and excellent printability. Engineers select this alloy for demanding aerospace, medical, and industrial parts. Its mechanical properties outperform most other titanium grades in additive manufacturing.

Can other titanium grades be used in 3D printing?

Yes. Manufacturers use grades like Ti-6Al-4V ELI (Grade 23), Grade 1, and Grade 2 for specific needs. Grade 23 suits medical implants. Grades 1 and 2 provide superior ductility and corrosion resistance for chemical and marine applications.

How does post-processing affect 3D-printed titanium parts?

Post-processing steps, such as heat treatment or machining, improve surface finish, fatigue life, and mechanical properties. These steps help parts meet industry standards and extend service life.

Is 3D-printed titanium safe for medical implants?

Regulatory bodies require strict testing and certification for medical implants. Ti-6Al-4V ELI (Grade 23) meets biocompatibility standards. Proper post-processing and validation ensure patient safety.

What factors influence the cost of 3D-printed titanium parts?

Material grade, powder quality, printing technology, and post-processing steps all impact cost. Ti-6Al-4V (Grade 5) costs more than commercially pure grades. Supply chain stability and recycling practices also affect pricing.