A wide and growing range of materials finds use in 3D printing, from common plastics to advanced metals and composites. Understanding material properties is key to successful 3D printing. The global 3D printing materials market was USD 1.53 billion in 2018, growing to an estimated USD 2,796.4 million in 2024. This market continues its rapid expansion, demonstrating significant future potential.

| Metric | Details |

|---|---|

| Market Size in 2025 (Value) | USD 3.88 Billion |

| Market Forecast in 2030 (Value) | USD 10.02 Billion |

| Growth Rate (CAGR) | 20.9% (2025-2030) |

| Forecast Period | 2025–2030 |

Key Takeaways

- Many materials work in 3D printing, from plastics to metals. Understanding these materials helps with good 3D printing.

- Plastic filaments are common for 3D printing. They include easy-to-use types like PLA and strong types like Nylon.

- Resins make very detailed 3D prints. They are good for models and parts needing smooth surfaces.

- Metal powders allow for strong, complex parts. These metals are used in planes and medical tools.

- Composite materials mix different things to make stronger parts. Carbon fiber composites are very strong and light.

- New materials like ceramics and concrete are changing building. Bioprinting uses hydrogels to make living tissues.

- Nanomaterials, like graphene, make 3D printed parts better. They improve strength and how well parts conduct electricity.

- Choosing the right material is important. It helps make sure the 3D printed part works well and saves money.

Plastic Filaments for 3D Printing

Plastic filaments represent the most common material type in 3D printing, particularly for Fused Deposition Modeling (FDM) technology. These materials offer versatility and accessibility for a wide range of applications.

Common Thermoplastics

Common thermoplastics are popular for their ease of use and affordability, making them ideal for many prototyping and consumer-level projects.

Polylactic Acid (PLA)

Polylactic Acid (PLA) is a biodegradable thermoplastic derived from renewable resources like corn starch or sugarcane. It is one of the easiest materials to print, known for its low warping and lack of strong odors during printing. However, PLA is relatively brittle and does not withstand high temperatures or prolonged outdoor exposure well.

Acrylonitrile Butadiene Styrene (ABS)

Acrylonitrile Butadiene Styrene (ABS) is a robust thermoplastic, widely recognized for its durability, impact resistance, and heat resistance. It requires a heated print bed to prevent warping and often produces fumes, necessitating good ventilation. ABS finds extensive use in functional prototypes and end-use parts.

Polyethylene Terephthalate Glycol (PETG)

Polyethylene Terephthalate Glycol (PETG) combines the best properties of PLA and ABS. It offers excellent durability, good impact resistance, and UV resistance, making it suitable for outdoor applications. PETG is also relatively easy to print, exhibiting less warping than ABS. Thermoplastics like ABS and polycarbonate are widely utilized in 3D printing for creating parts across numerous industries, including aerospace, medical, automotive, and electronics. They are particularly crucial, and sometimes the only viable option, for producing finished goods.

Engineering-Grade Filaments

Engineering-grade filaments offer enhanced mechanical properties, making them suitable for more demanding applications where strength, durability, and heat resistance are critical.

Nylon (PA) for 3D Printing

Nylon (Polyamide, PA) is a highly durable and flexible material with excellent wear and impact resistance. It absorbs moisture, which requires careful storage and drying before printing. Nylon is often chosen for gears, hinges, and other functional parts requiring resilience.

Polycarbonate (PC) for 3D Printing

Polycarbonate (PC) is an exceptionally strong and rigid material with high heat resistance. It is challenging to print due to its high melting point and tendency to warp, but it produces parts with superior mechanical properties. PC is ideal for components requiring high strength and durability.

High Impact Polystyrene (HIPS)

High Impact Polystyrene (HIPS) shares many properties with ABS, including durability and impact resistance. It often serves as a support material for ABS prints because users can dissolve it in limonene, leaving the main print intact.

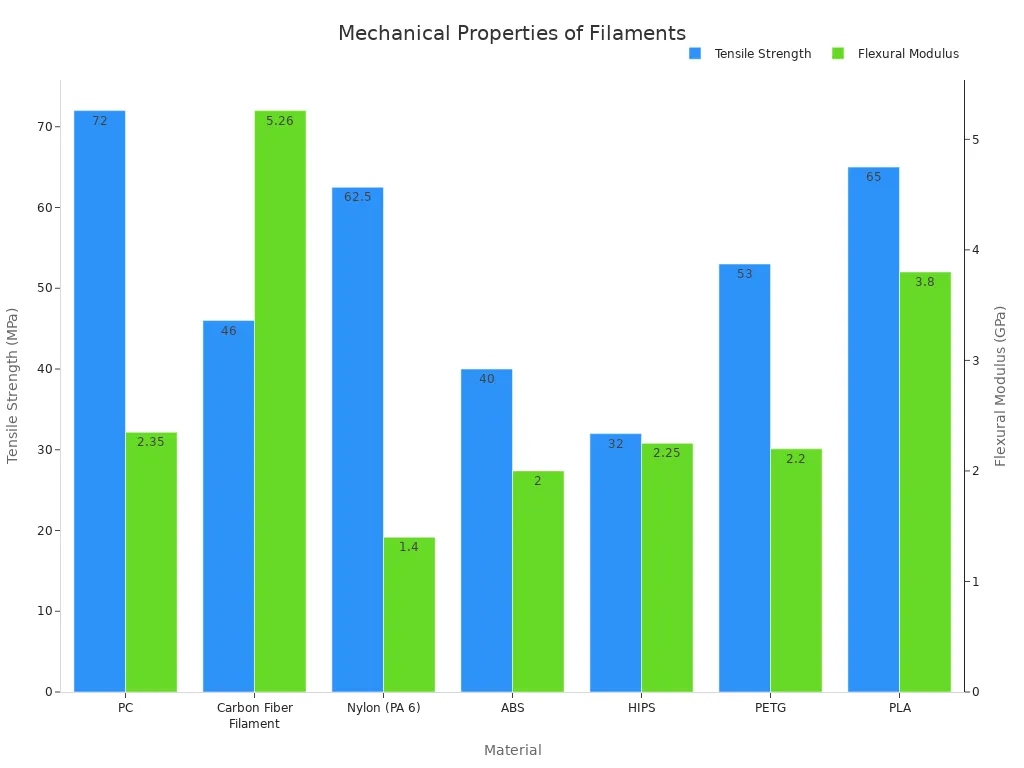

Engineering-grade filaments like Nylon and PC are distinguished from common thermoplastics by their superior mechanical properties, including enhanced durability, wear resistance, impact resistance, and heat resistance. For instance, Polycarbonate (PC) is noted for its high strength and durability, along with a high glass transition temperature of 150°C, making it suitable for high-temperature applications. Nylon (PA 6) is recognized for its excellent durability, wear resistance, and impact resistance. While common thermoplastics like ABS offer good durability and impact resistance, and PETG is highly durable, engineering-grade materials often provide a more robust combination of these properties, or excel significantly in specific areas like high-temperature performance or stiffness, as seen with Carbon Fiber filament’s high flexural modulus.

| Material Type | Material | Tensile Strength (MPa) | Flexural Modulus (GPa) | Other Differentiating Properties |

|---|---|---|---|---|

| Engineering-Grade | PC | 72 | 2.2 – 2.5 | High strength, durability, high glass transition temperature (150°C) |

| Carbon Fiber Filament | 46 | 5.26 | Enhanced mechanical properties, better dimensional stability, more brittle | |

| Nylon (PA 6) | 40 – 85 | 0.8 – 2 | Excellent durability, wear resistance, impact resistance | |

| Common Thermoplastics | ABS | 40 | 1.6 – 2.4 | Durable, high impact resistance, good wear resistance |

| HIPS | 32 | 1.5 – 3 | Durable, flexible, strong | |

| PETG | 53 | 2.2 | Highly durable, UV-resistant | |

| PLA | 65 | 3.8 | Brittle, cracks easily, cannot withstand long-term outdoor exposure |

Engineering-grade filaments find extensive use in various industrial applications:

- PEI (Polyetherimide) / ULTEM™: Used in aviation, automotive, electronic, and medical sectors for parts requiring high heat and chemical resistance. Specific applications include electric and lighting systems (headlamps, ignition/engine elements, electric switches, frames, bulb sockets), and medical devices (disposable/multiple-use devices, probe casings, monitors).

- PEEK (Polyetheretherketone): Applied in the medical sector (dental instruments, endoscopes, dialysers), automotive (bearings, piston parts, pumps, valves, insulation), and aviation (replacing metal elements in engines, external structure components for corrosion resistance, corrugated tubes for cable/fiber optic protection).

- PEKK (Polyetherketoneketone): Utilized in automotive and chemical sectors for structural elements (gear wheels, sleeves, bearings, shafts, ball valve sealing). Also used in medicine (dental instruments, medical implants) and for food contact items (kitchen utensils) due to its sterilizability. It replaces steel in some applications, such as elements for belt oil skimmers.

- PA-CF (Carbon Fiber Reinforced Polyamide) & PA-GF (Glass Fiber Reinforced Polyamide): Primarily used in the aviation sector for parts of unmanned planes and as material for production tools, often replacing metal elements due to their thermal resistance, hardness, and durability.

Flexible and Specialty Filaments

Flexible and specialty filaments expand the capabilities of 3D printing, allowing for unique functional and aesthetic properties.

Thermoplastic Polyurethane (TPU)

Thermoplastic Polyurethane (TPU) is a highly flexible, rubber-like material known for its elasticity and abrasion resistance. It is ideal for creating parts that require bending, stretching, or impact absorption.

Wood-Filled Filaments

Wood-filled filaments combine plastic (often PLA) with wood fibers, giving prints a wood-like appearance, texture, and even scent. These filaments are popular for aesthetic models, decorative items, and artistic projects.

Conductive Filaments

Conductive filaments incorporate conductive particles, such as carbon black or graphene, into a plastic base. These materials allow for the printing of electrically conductive traces, enabling the creation of basic electronic circuits or touch sensors.

Flexible and specialty filaments possess unique properties that enable specific applications:

| Filament Type | Unique Property | Specific Application |

|---|---|---|

| Flexible (e.g., TPU) | Rubber-like characteristics | Producing rubber-like objects |

| Metallic (infused with metal powders) | Metallic finish | Prints with a metallic appearance |

| Conductive | Electrical conductivity | Prototyping electronic circuits |

| Biodegradable | Eco-friendly composition | Environmentally conscious projects |

These materials find diverse use cases in both consumer and industrial settings:

- Industrial: Functional prototyping and fit testing (e.g., phone cases, seals), custom tooling with ductile elements (handles, gripper parts), end-use parts with rubber-like properties (softer contact points on production lines to avoid damaging goods), custom tooling in the automotive industry (e.g., for vehicle panels and wheels to reduce damage during assembly), spare parts for product packaging lines (e.g., directing beer bottles on a conveyor belt).

- Consumer: Functional prototyping and fit testing (e.g., phone cases), product and industrial design (e.g., bike handles).

- Industrial (Medical & Healthcare): Customized prosthetic limbs, custom orthotics, patient-specific surgical guides.

- Industrial (Automotive & Aerospace): Flexible engine seals (withstanding extreme temperatures and pressures), aerospace gaskets (maintaining pressure integrity).

- Consumer: Customized shoe soles, durable and personalized phone cases, custom-fit sports braces and supports, articulated figures, interactive art installations.

Resins for Detailed 3D Printing

Resins offer exceptional detail and smooth surface finishes, making them ideal for applications requiring high precision and aesthetic quality. Stereolithography (SLA) and Digital Light Processing (DLP) technologies primarily utilize these liquid photopolymer materials.

Standard and Clear Resins

Standard and clear resins provide excellent resolution and surface quality for a wide range of prototyping and visual model applications.

General Purpose Resins

General purpose resins, often available in black, white, or grey, produce high-stiffness, high-resolution prints. They offer a smooth, injection molding-like finish and capture fine features with high detail. Users find these resins excellent for prototypes and models, providing a matte, opaque appearance. They also serve as a good base for painting or other finishing processes. Standard resins are ideal for rapid prototyping and visual models, producing parts with smooth surfaces and high detail. They are perfect for presentation models or fit-checking prototypes where aesthetics and surface finish are prioritized over mechanical strength. They are commonly used in prototyping for creating early-stage designs, visual models, fit testing, and concept verification due to their balance of cost and precision.

Transparent Resins

Transparent resins allow for the creation of parts with optical clarity. They produce fine features and high detail with a smooth surface finish. Users can post-process these resins to achieve near optical transparency. Clear resin is suitable for transparent applications such as fluidics, mold making, optics, and lighting. It also works well for any parts requiring translucency. High Clear Resin can produce excellent transparent objects like prototypes, gifts, or jewelry.

Functional Resins

Functional resins offer enhanced mechanical and thermal properties, extending the utility of resin 3D printing beyond basic prototyping to demanding engineering applications.

Flexible Resins

Flexible resins exhibit elasticity and flexibility. They can bend and stretch without breaking, mimicking rubber-like characteristics. This makes them suitable for producing rubber-like objects, seals, gaskets, and other components requiring pliability and impact absorption.

Tough and Engineering Resins

Tough and engineering resins provide superior mechanical properties compared to standard resins. They offer enhanced strength, impact resistance, and fatigue resistance. These resins often possess a good balance of flexibility and rigidity. Engineering resins are crucial for functional prototypes, tooling, and production parts in general manufacturing, where dimensional stability ensures proper fit and functionality. The automotive sector uses them for engine components and heat shields, while the aerospace industry benefits from their robust properties for lightweight yet strong parts.

Castable Resins

Castable resins are specifically designed for investment casting processes. They burn out cleanly without leaving ash or residue, making them ideal for creating patterns for jewelry, dental prosthetics, and other intricate metal parts. These resins simplify the casting workflow, offering high detail and accuracy for complex geometries.

Metal Powders in 3D Printing

Metal powders have revolutionized manufacturing, enabling the creation of complex, high-performance parts. These materials are crucial for various additive manufacturing processes, including Selective Laser Melting (SLM) and Electron Beam Melting (EBM).

Common Metal Alloys

Common metal alloys offer robust solutions for industrial applications. They provide strength, durability, and specific functional properties.

Stainless Steel for 3D Printing

Stainless steel powders produce strong, corrosion-resistant parts. Manufacturers use them for tooling, medical instruments, and automotive components.

Aluminum Alloys for 3D Printing

Aluminum alloys are lightweight and possess excellent strength-to-weight ratios. They find applications in aerospace and automotive industries where weight reduction is critical.

Titanium Alloys for 3D Printing

Titanium alloys are known for their exceptional strength, biocompatibility, and corrosion resistance. The medical and aerospace sectors frequently use them for implants and high-performance components.

These common metal alloys are vital across several industrial sectors:

- Aerospace industry: It utilizes 3D printed metal for lightweight components, engine parts (fuel nozzles, turbine blades), and satellite structures.

- Automotive sector: It employs metal 3D printing for rapid prototyping, custom tooling (jigs, fixtures, molds), and performance parts for high-end vehicles.

- Medical and dental industries: It leverages the technology for custom implants (hip, knee, spinal), specialized surgical instruments, and dental prostheses (crowns, bridges).

- Industrial and manufacturing: It applies metal 3D printing for on-demand spare parts, custom tooling with complex cooling channels, and optimized heat exchangers.

- Energy sector: It benefits from metal 3D printing for optimized turbine components, custom oil and gas equipment (valves, pumps), and specialized nuclear industry parts.

Precious and High-Performance Metals

Precious and high-performance metals extend the capabilities of additive manufacturing to highly specialized and demanding fields.

Gold and Silver for 3D Printing

Gold and silver powders enable the creation of intricate designs for jewelry and luxury goods. This technology offers significant design freedom and customization. Jewelers use it for low-batch, high-end applications, saving time compared to hand carving. Material Jetting with highly conductive silver or gold inks also allows 3D printing of electronic devices like antennas and PCB prototypes.

Nickel-Based Superalloys

Nickel-based superalloys offer exceptional strength and heat resistance, even at extreme temperatures. The aerospace and energy sectors rely on them for turbine components and other critical parts.

Using these materials in 3D Printing provides several advantages. Engineers can tailor performance by selecting specific alloys for optimal thermal conductivity, strength, or corrosion resistance. This strategic material placement reduces overall component weight, crucial for aerospace fuel efficiency. The process also consolidates parts, combining multiple components into a single unit, eliminating assembly needs. For industries like jewelry, watchmaking, and dental, this technology offers unparalleled customization and design freedom. It allows for rapid prototyping and significantly reduces lead times. Furthermore, it minimizes waste, using only the necessary material, which leads to cost savings, especially for expensive high-performance alloys. This approach also lowers manufacturing costs compared to traditional methods by reducing material waste and staffing needs through increased automation.

Composite Materials for 3D Printing

Composite materials combine two or more distinct materials to create a new material with enhanced properties. In 3D printing, these materials offer superior strength, stiffness, and other functional characteristics compared to single-component materials. They significantly expand the capabilities of additive manufacturing.

Fiber-Reinforced Composites

Fiber-reinforced composites integrate high-strength fibers into a polymer matrix. This combination dramatically improves the mechanical performance of 3D printed parts.

Carbon Fiber Composites

Carbon fiber composites incorporate carbon fibers into a polymer base. These materials offer an exceptional strength-to-weight ratio, making them ideal for structural applications. They possess excellent tensile strength, resisting significant pulling forces without breaking. Carbon fiber composites also show good fatigue resistance, maintaining integrity under repeated stress cycles. Their low thermal expansion ensures stable dimensions across varying temperatures. Some types are electrically conductive and corrosion resistant. For example, a core-shell TLCP-polyamide composite achieved a 50% improvement in tensile strength and a 300% higher tensile modulus compared to its counterparts. These composites find use in aerospace for lightweight load-bearing structures and in sporting goods for frames and protective gear. They are also crucial for brackets and mounts in drones and under-the-hood components in automotive applications.

Glass Fiber Composites

Glass fiber composites use glass fibers within a polymer matrix. They provide a good balance of mechanical properties at a lower cost than carbon fiber. Glass fiber composites offer good strength and stiffness. They are excellent electrical insulators and show good chemical resistance. These materials also possess high impact strength, absorbing significant energy without fracturing. They provide good thermal insulation and are transparent to radio frequencies. A BF/PLA/PLA-g-STMAH composite system demonstrated a more than twofold increase in both tensile strength and Young’s modulus. Applications include industrial tooling, medical and orthotics, and molds for short-run manufacturing.

Other Composite Materials

Beyond fiber reinforcement, other composite materials bring unique properties to 3D printing, enabling specialized applications.

Ceramic Composites

Ceramic composites combine ceramic particles or fibers within a matrix. These materials offer extremely high temperature resistance, operating at temperatures exceeding 1000°C. They exhibit high hardness and wear resistance, along with excellent strength and stiffness at elevated temperatures. Ceramic composites are also highly resistant to corrosion and oxidation. Technical ceramics, for instance, are used in advanced manufacturing for components requiring extreme heat and wear resistance.

Metal Matrix Composites

Metal matrix composites (MMCs) embed reinforcing materials, such as ceramic particles or fibers, into a metallic matrix. These composites provide enhanced strength and stiffness, especially at elevated temperatures, surpassing unreinforced metals. They also show improved wear resistance and often possess higher thermal conductivity. MMCs find applications in aerospace and automotive industries for components needing superior performance under demanding conditions. For example, they are used in structural components for next-generation electric vehicles and in advanced robotics for actuators.

Advanced and Emerging Materials in 3D Printing

Advanced and emerging materials push the boundaries of additive manufacturing. They enable new applications across various industries. These materials offer unique properties, from extreme heat resistance to biocompatibility.

Ceramics and Concrete

Ceramics and concrete are transforming construction and high-performance component manufacturing.

Technical Ceramics

Technical ceramics offer exceptional properties for demanding environments. 3D printing allows for the creation of materials with complex porous structures. These structures exhibit good mechanical properties. They also show great potential for thermal insulation, although creating structural composites with good insulating properties remains challenging. Porous structures are characterized by low relative density and a large specific surface area. Producing high-density ceramic pieces without flaws remains a challenge. Accelerating the production process of ceramic 3D printing is still a difficulty. However, 3D printing enables direct manufacturing of intricate ceramic products tailored to design requirements. It allows for quick and accurate creation of complex product structures, overcoming limitations of traditional molding. This facilitates the full utilization of ceramics’ excellent properties, such as high strength, low density, corrosion resistance, and electrical insulation, in fields like automotive, aerospace, electronics, and medicine.

Concrete for Large-Scale 3D Printing

Concrete 3D printing is revolutionizing construction. Researchers have developed materials like TES-3DPC with 30% HC-PCMs. This material maintains mechanical integrity with a compressive strength of 48.1 MPa and an elastic modulus of 29.4 GPa. It also improves thermal comfort, reducing internal temperature fluctuations by 6.8 °C and the overheating degree from 3.3 °C·h to 1.12 °C·h. Its specific heat capacity increases by 45.43% to 1.82 J/g·°C. Another example, RCP-2-0-1 (20% cement replaced by RCP), shows an anisotropic compressive strength of 55.9 MPa and an anisotropic flexural strength of 12.49 MPa. This optimal mixture demonstrates impressive heat resistance, with an 11.7% compressive strength increase at 300 °C.

| Material Composition | Property | Value | Notes |

|---|---|---|---|

| TES-3DPC with 30% HC-PCMs | Compressive Strength | 48.1 MPa | Mechanical integrity maintained |

| TES-3DPC with 30% HC-PCMs | Elastic Modulus | 29.4 GPa | Mechanical integrity maintained |

| TES-3DPC with 30% HC-PCMs | Reduction in Internal Temperature Fluctuations | 6.8 °C | Improved thermal comfort |

| TES-3DPC with 30% HC-PCMs | Overheating Degree (OD) | Reduced from 3.3 °C·h to 1.12 °C·h | Improved thermal comfort |

| TES-3DPC with 30% HC-PCMs | Specific Heat Capacity | 1.82 J/g·°C | 45.43% increase from 0% HC-PCMs (1.25 J/g·°C) |

Concrete mix proportions heavily influence the 3DCP process. Excessive use of waste materials can decrease early strength. Using recycled sand can reduce flexural stiffness and strength when objects are loaded from different directions. Despite these limitations, concrete 3D printing enables the creation of complex and customized structures. It offers advantages in minimizing construction waste and contributes to faster building processes. Optimizing printing ink with waste materials can lead to better economic and environmental outcomes.

Bioprinting and Food-Grade Materials

Bioprinting and food-grade materials are opening new frontiers in medicine and nutrition.

Hydrogels for Bioprinting

Hydrogels are crucial for bioprinting, which involves creating living tissue products like bones or skin. This field is largely in the research and development phase. While no FDA-approved biological products incorporate additive manufacturing, the FDA has engaged with those using additive manufacturing for biological materials. The FDA does not clear or approve materials for medical uses in isolation. Instead, materials are evaluated within the context of a device’s technological characteristics and intended use. Bioprinting is used in transplantology, regenerative medicine, and reproductive medicine. Printed tissues are utilized in experimental pharmacology for drug and toxicity testing, and in cosmetology. It offers the potential to replace diseased organs, addressing organ shortages. Successes include the promising possibility of replacing bones, cartilage, blood vessels, and internal organs.

Edible Materials for 3D Printing

Edible materials allow for personalized food creation. This technology enables customized shapes, textures, and nutritional content. Chefs and food scientists explore these materials for unique culinary experiences and dietary solutions.

Nanomaterials and Graphene

Nanomaterials and graphene significantly enhance the performance of 3D printed components.

Graphene-Enhanced Filaments

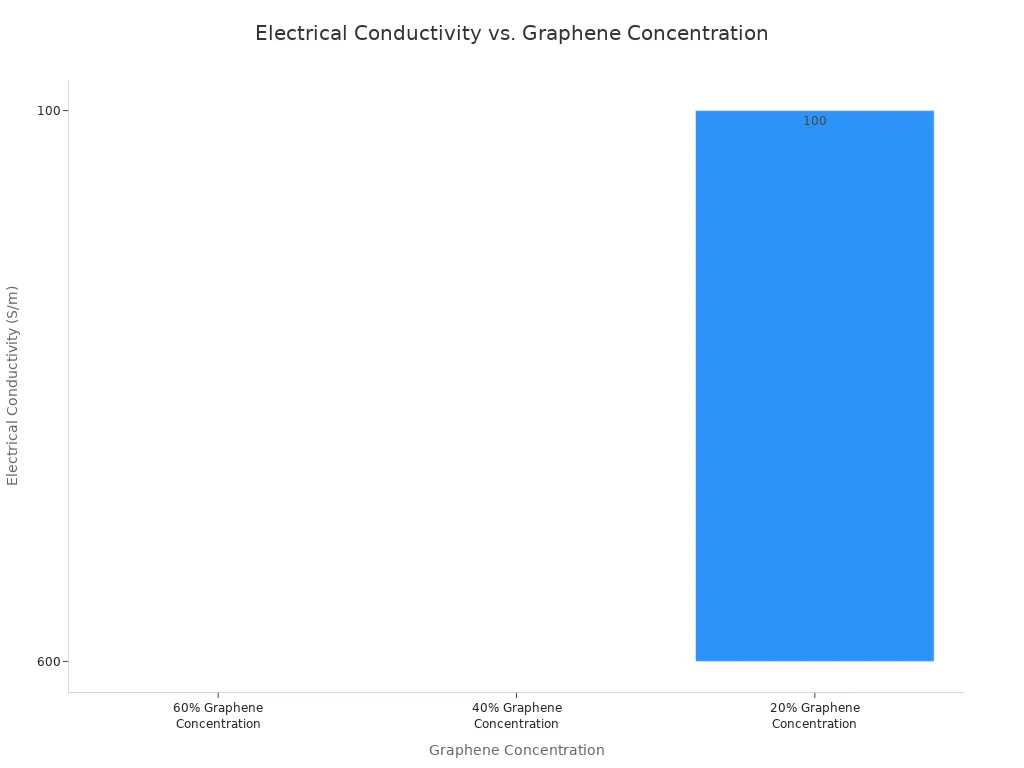

Graphene and its derivatives, used as nanofillers in polymer-based scaffolds, improve mechanical, thermal, electrical, and chemical properties. This includes strength and toughness, by forming strong bonds with polymer interfaces. The aspect ratio of graphene sheets critically influences mechanical properties, electrical conductivity, and interfacial interactions. A higher aspect ratio generally improves mechanical strength and conductivity. Graphene enhances the electrical conductivity of polymers by forming a conductive network of free electrons. Incorporating 5% carbon fiber and varying quantities of graphene nanoplatelets into Polyethylene terephthalate (PET) thermoplastics results in significantly improved electrical conductivity and mechanical properties. PLA-based graphene composites demonstrate a 1.7 times improvement in tensile and flexural stress.

Nanomaterial Integration in 3D Printing

Nanomaterials offer significant performance advantages in various applications. Graphene combined with hydroxyapatite (HA) microparticles in a composite ink supports bone tissue regeneration. Graphene scaffolds (60% concentration) supported the viability and proliferation of Mesenchymal Stem Cells (MSCs) and induced axonal elongation. 3D printed PCL-graphene scaffolds, when implanted in rat calvarium defects, resulted in higher tissue formation. 3D printing technology also develops ultralight graphene aerogel microlattices. These are notable for their superior mechanical properties, high surface area, and extraordinary electrical and thermal conductivity.

The versatility of 3D printing materials rapidly expands, with innovation driving new applications across diverse industries. Choosing the right material is critical for optimal performance and desired outcomes.

Selecting the appropriate material requires careful consideration of project needs, including mechanical strength, flexibility, heat resistance, and compatibility with specific 3D printing technologies.

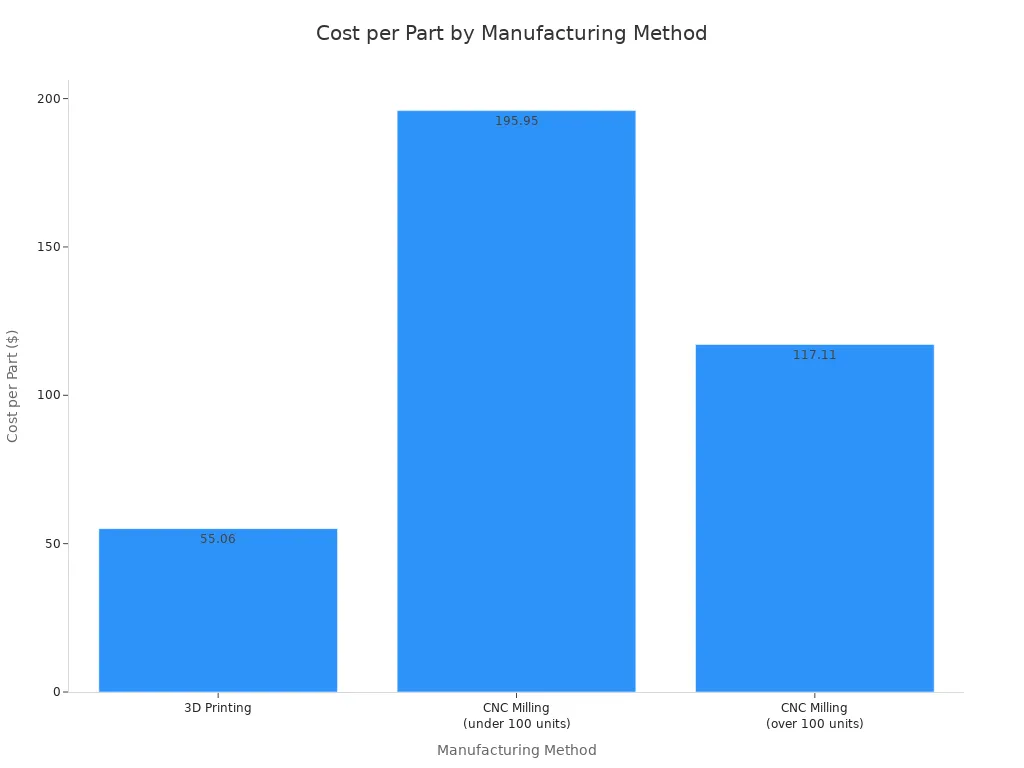

Strategic material selection offers significant economic benefits. For instance, using fiberglass instead of carbon fiber for a brake lever can save $31.27 per part. This optimization directly impacts cost efficiency and enhances return on investment.

3D printing often provides substantial savings compared to traditional manufacturing methods.

FAQ

What is the easiest material to 3D print?

Polylactic Acid (PLA) is generally the easiest material to 3D print. It derives from renewable resources. PLA exhibits low warping and does not produce strong odors during printing. However, it is brittle and lacks high-temperature resistance.

Which 3D printing materials offer the highest strength?

Engineering-grade filaments like polycarbonate and nylon provide high strength. Metal alloys such as titanium and stainless steel offer exceptional durability. Carbon fiber composites also deliver superior strength-to-weight ratios for demanding applications.

Can 3D printers use metal?

Yes, 3D printers utilize metal powders. Processes like Selective Laser Melting (SLM) and Electron Beam Melting (EBM) fuse these powders. This technology creates complex, high-performance metal parts for various industries, including aerospace and medical.

What materials are used for flexible 3D prints?

Thermoplastic Polyurethane (TPU) is a popular flexible filament. Flexible resins also provide elasticity for detailed prints. These materials allow for parts that bend, stretch, and absorb impact, ideal for seals, gaskets, and rubber-like objects.

Is 3D printing concrete possible for construction?

Yes, concrete 3D printing is transforming construction. It enables the creation of complex and customized structures. This method minimizes construction waste and contributes to faster building processes for large-scale projects.

What are bioprinting materials?

Hydrogels are crucial for bioprinting. This advanced technique creates living tissue products, such as bones or skin. Bioprinting holds potential for transplantology, regenerative medicine, and drug testing, addressing organ shortages.

Why are composite materials used in 3D printing?

Composite materials combine distinct components to enhance properties. Fiber-reinforced composites, like carbon fiber, offer superior strength and stiffness. They expand 3D printing capabilities for high-performance applications beyond single-component materials.

How do nanomaterials improve 3D printing?

Nanomaterials, such as graphene, significantly enhance 3D printed components. They improve mechanical strength, thermal properties, and electrical conductivity. Graphene-enhanced filaments, for example, show improved tensile and flexural stress.