Titanium Alloy Heat Treatment Processes: What to Know involves precise heating and cooling to enhance the performance of titanium alloys. Engineers apply these methods to achieve several objectives:

- Stress relieving reduces residual stresses from fabrication, lowering the risk of distortion and cracking.

- Annealing improves ductility and machinability while stabilizing dimensions and structure.

- Solution treating and aging increase strength by refining the alloy’s microstructure.

- Optimization of special properties boosts fracture toughness, fatigue strength, and resistance to high-temperature creep, supporting reliability in aerospace, medical, and industrial components.

Key Takeaways

- Heat treatment improves titanium alloys by adjusting strength, ductility, toughness, and corrosion resistance to meet specific needs.

- Different processes like annealing, stress relieving, solution treatment, aging, and beta annealing create unique microstructures that affect mechanical properties.

- Choosing the right heat treatment depends on the alloy type and application, with alpha, alpha-beta, and beta alloys responding differently to treatments.

- Precise control of temperature, time, atmosphere, and cooling rates is essential to avoid defects and achieve desired performance.

- Quality checks after heat treatment, including hardness and non-destructive testing, ensure components meet strict standards for reliability.

Main Types of Titanium Alloy Heat Treatment Processes: What to Know

Annealing

Annealing stands as a foundational process in titanium alloy heat treatment. Engineers use annealing to refine the microstructure, enhance ductility, and relieve internal stresses. During annealing, the alloy undergoes controlled heating, typically at temperatures around 800°C for alloys like Ti552. At this temperature, the α-phase transforms from a striated to an equiaxed structure, and the intergranular β-phase increases. As the annealing temperature rises, grain size grows and the volume fraction of the α-phase decreases. This shift leads to a reduction in tensile strength and hardness, but elongation improves, which means the material becomes more ductile.

A key benefit of annealing is the transformation of brittle α′ martensite into a mixture of α and β phases. This change increases ductility and shifts the fracture mode from brittle to ductile. For example, annealing Ti-6Al-4V below the β phase transition temperature (around 840°C) can double the maximum elongation, making the alloy more suitable for forming and machining. Hot isostatic pressing (HIP) at 930°C and 100 MPa for several hours further enhances ductility by homogenizing lattice distortions and rearranging dislocations at grain boundaries.

Tip: Annealing near or just below the β phase transition temperature allows for precise tailoring of mechanical properties. However, higher annealing temperatures may reduce strength, so process selection should match the intended application.

| Alloy | Annealing Temperature Range (°C) | Holding Time | Cooling Method | Microstructural Notes |

|---|---|---|---|---|

| Ti-6242S | 940 – 1050 | 1 hour | Argon gas (~80°C/min) | Below β transus: bimodal α + transformed β; Above β transus: fully transformed β |

| Ti552 | Around 800 | N/A | N/A | α-phase morphology and β-phase volume change |

Stress Relieving

Stress relieving targets the reduction of residual stresses that develop during manufacturing processes such as welding, forging, or additive manufacturing. These stresses, if left untreated, can lead to distortion, cracking, or premature failure in service. In the context of Titanium Alloy Heat Treatment Processes: What to Know, stress relieving involves heating the alloy to a moderate temperature, typically 500–600°C, and holding it for a specified duration.

For Ti6Al4V produced by laser powder bed fusion, low-temperature stress-relief annealing at 350°C for 600 minutes can nearly eliminate residual stress without altering the phase composition. Micro-hardness measurements show that annealed specimens consistently exhibit higher hardness than as-built specimens. The increase in hardness results from partial decomposition of the acicular α′ phase into smaller substructures, which improves the uniformity of the microstructure.

| Titanium Alloy | Annealing Temperature (°C) | Annealing Time (hours) | Cooling Method |

|---|---|---|---|

| Grade IV Ti | 600 | 6 | Air/Furnace |

| Ti-6Al-4V | 600 | 6 | Air/Furnace |

| Ti-13Nb-13Zr | 500 | 1 | Air/Furnace |

- Annealing temperature should remain 50–200°C below the alloy’s recrystallization temperature.

- Soaking time must be sufficient for effective stress relief; longer times do not harm strength or ductility.

- Uniform cooling, either by air or furnace, is recommended to avoid thermal gradients.

Note: For Ti-6Al-4V, air cooling is preferred to prevent the formation of the Ti3Al phase, which can reduce corrosion resistance.

Solution Treatment and Aging

Solution treatment and aging (STA) represent advanced Titanium Alloy Heat Treatment Processes: What to Know, especially for high-performance alloys like Ti6Al4V. This process involves heating the alloy into the dual α-β phase region, typically near or above 820°C. At this stage, the α-phases dissolve into the β-matrix, resulting in fine, supersaturated β-grains. The subsequent cooling rate plays a crucial role: air cooling produces a more uniform microstructure and reduces the formation of brittle α′ phases compared to water quenching.

After solution treatment, the alloy undergoes aging at a lower temperature, often around 510°C. During aging, fine αs-phase precipitates form within the β-grains, strengthening the alloy. The amount and morphology of these precipitates depend on the aging temperature. Higher aging temperatures increase precipitation but can cause coarsening, which negatively affects plasticity and fracture toughness.

Solution treatment and aging can increase tensile strength by about 20% compared to mill annealing. The process also enhances ductility, making it ideal for aerospace applications. The microstructure, whether equiaxed or lamellar, influences fatigue and strength properties. Equiaxed structures provide better resistance to fatigue initiation, while lamellar structures offer improved resistance to fatigue propagation.

- Solution treatment near the phase transformation temperature dissolves α-phases into the β-matrix.

- Aging precipitates strengthening αs-phases from supersaturated β-grains.

- Air cooling after solution treatment yields more uniform microstructures and reduces brittle phase formation.

- Coarse αs-phases are detrimental due to limited slip systems in the hcp α-phase, causing stress concentration.

Tip: Optimal STA parameters depend on the specific alloy and desired balance between strength and ductility. For TB6 alloy, solution treatment at 820°C with air cooling followed by aging at 510°C produces the best combination of uniformity and mechanical performance.

Beta Annealing

Beta annealing stands out among Titanium Alloy Heat Treatment Processes: What to Know due to its unique temperature range and resulting microstructure. Engineers perform beta annealing near or slightly above the α + β/β phase-transition temperature, typically around 875–880°C for alloys like Ti555211. At this elevated temperature, the alloy transforms into a single β phase, causing the α phase to disappear. After holding at this temperature, the material is air cooled, which leads to the formation of a coarse, layered, and needle-like α phase structure known as the Widmanstätten microstructure.

Key characteristics that distinguish beta annealing from other heat treatments include:

- The process occurs near or above the β transus temperature, producing a single β phase during heating.

- Air cooling after beta annealing results in needle-like α phase near grain boundaries and Widmanstätten structures.

- The resulting microstructure increases strength but causes stress concentration, leading to brittle fracture behavior with almost no ductility and absence of yield strength.

- Compared to double annealing or solution treatment and aging, beta annealing produces lower ductility and a less favorable balance between strength and toughness.

- Double annealing creates an equiaxed crystal structure with higher elongation but lower strength.

- Solution treatment and aging yield fine secondary α phase precipitates, improving both strength and toughness.

The recommended beta annealing cycle involves solution treating the alloy at about 15°C above the beta transus, followed by air cooling. Stabilization then occurs at 650°C to 760°C. This cycle produces the Widmanstätten α–β colony microstructure, which is desirable for certain beta titanium alloys. However, the trade-off remains: beta annealing provides high strength but at the cost of ductility and toughness. Engineers must carefully select this process when the application demands maximum strength and can tolerate reduced ductility.

Note: Beta annealing is best suited for applications where high strength is critical, but the component will not experience significant deformation or impact loading.

Quenching and Tempering

Quenching and tempering represent another important category within Titanium Alloy Heat Treatment Processes: What to Know. This two-step process allows engineers to tailor the hardness, strength, and toughness of titanium alloys for demanding applications.

The key steps in quenching and tempering include:

- Quenching involves rapidly cooling the alloy from the all-beta phase region, usually by water quenching. This rapid cooling suppresses the formation of the alpha phase and retains the beta phase.

- Some titanium alloys undergo a martensitic or shear-like transformation during quenching, forming an alpha prime (α′) phase. This transformation distorts the lattice and produces a hard, tough material with improved fatigue properties.

- Tempering follows quenching. The alloy is reheated to a temperature below the beta transus and held for a controlled period.

- The outcome of tempering depends on the phases present, the holding time, and the tempering temperature.

- If the initial structure contains alpha prime, it transforms into alpha during tempering. Prolonged tempering causes the alpha phase to become serrated, which decreases hardness and strength but increases ductility and impact resistance.

- In alpha-beta structures, the alpha phase remains mostly unchanged, while the beta phase decomposes to form more alpha. Lower tempering temperatures produce more alpha, resulting in a greater decrease in strength and hardness but increased ductility compared to higher tempering temperatures.

- The process often ends with a re-quenching step to finalize the microstructure.

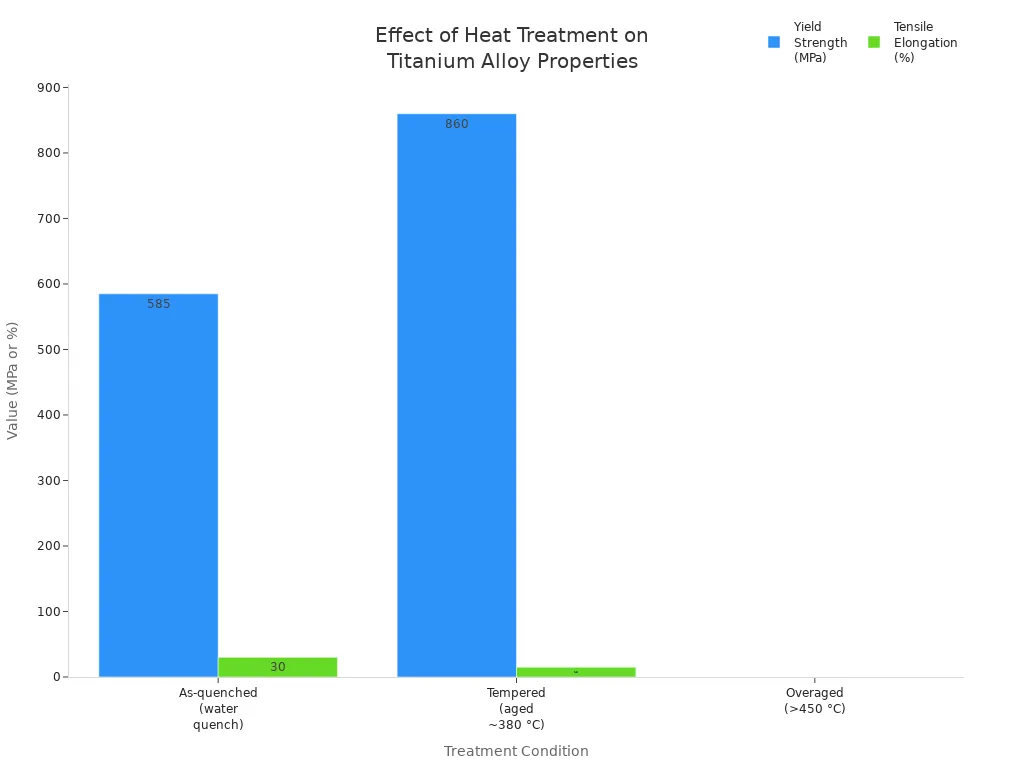

The changes in hardness and toughness during quenching and tempering can be summarized as follows:

| Treatment Condition | Microstructure | Yield Strength (MPa) | Tensile Elongation (%) | Notes on Hardness and Toughness Changes |

|---|---|---|---|---|

| As-quenched (water quench) | Supersaturated α′a martensite | ~585 | ~30 | Moderate strength and ductility; amenable to age hardening |

| Tempered (aged ~380 °C) | Precipitation hardened α′a martensite with fine U2Ti precipitates | ~860 | ~15 | Increased hardness/strength; decreased toughness/ductility |

| Overaged (>450 °C) | Cellular decomposition of martensite | Decreasing from peak | Little recovery | Strength decreases; toughness remains low due to overaging |

Quenching produces a martensitic microstructure with moderate hardness and good toughness. Tempering increases hardness and strength through precipitation hardening but reduces ductility. Overaging leads to a drop in strength, with little recovery in toughness. Engineers must balance these changes to meet the specific requirements of each application.

Tip: For optimal results, control the quenching and tempering parameters closely. Monitor the microstructure and mechanical properties to ensure the desired combination of strength and toughness.

Effects of Titanium Alloy Heat Treatment Processes: What to Know

Strength and Hardness

Heat treatment processes play a crucial role in determining the strength and hardness of titanium alloys. Each process, from annealing to solution treatment and aging, produces distinct effects on mechanical properties. Annealing reduces residual stresses, which improves flexibility and toughness. Stress relieving ensures stability and consistent performance by minimizing internal stresses. Beta annealing refines the microstructure, leading to better fracture toughness and fatigue strength. Solution treatment and aging create fine precipitates that significantly enhance strength and fatigue resistance.

| Heat Treatment Process | Impact on Titanium Alloys | Key Effects on Strength and Hardness |

|---|---|---|

| Annealing | Reduces residual stresses | Improves flexibility and toughness, enhancing structural integrity |

| Stress Relieving | Reduces internal stresses | Ensures stability and consistent performance |

| Beta Annealing | Heating to beta phase field followed by controlled cooling | Refines microstructure, improves fracture toughness and fatigue strength |

| Solution Treatment and Aging | Creates homogeneous single-phase structure + controlled aging | Forms fine precipitates, significantly enhances strength and fatigue resistance |

Quantitative changes also highlight the impact of heat treatment. For example, single-stage heat treatment of Ti–6Al–4V at 935°C increases both tensile strength and hardness due to the formation of a brittle martensite phase. Duplex-stage treatments at 600°C and 700°C further increase yield and ultimate tensile strength, with higher retained beta-phase fractions at elevated temperatures.

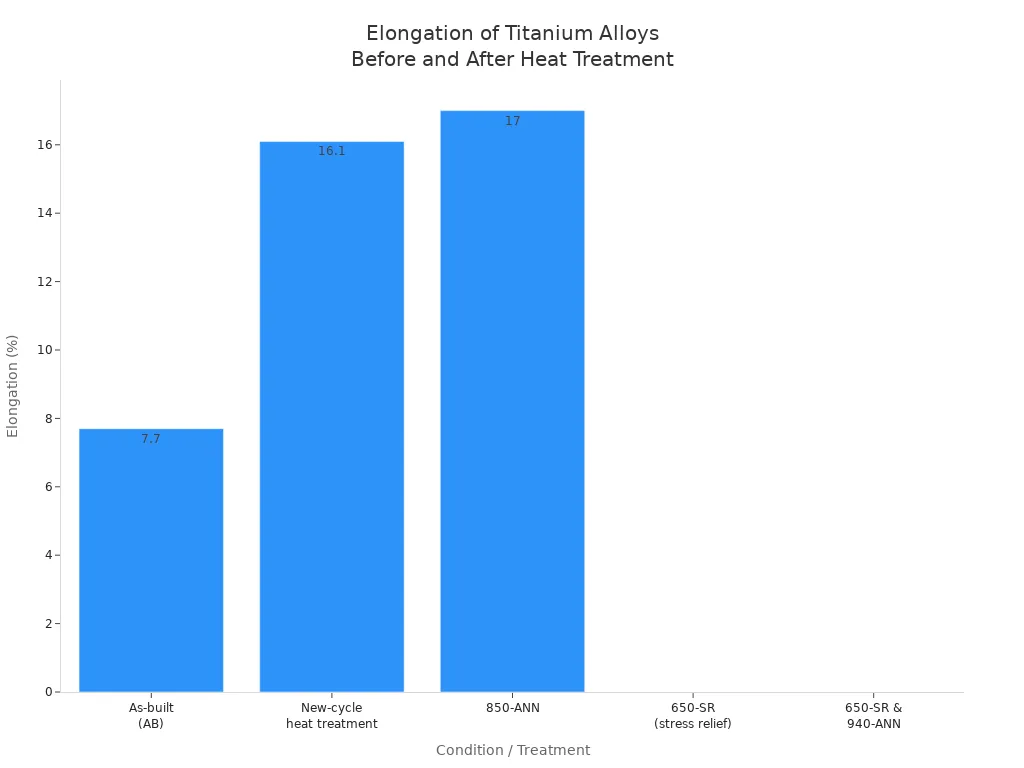

Ductility and Toughness

Titanium Alloy Heat Treatment Processes: What to Know also influence ductility and toughness. Proper heat treatment can increase elongation and impact toughness, making alloys suitable for demanding applications. For instance, elongation values often rise from about 7.7% in as-built conditions to over 14% after multi-stage heat treatment. Impact toughness improves as microstructures become more refined and secondary alpha precipitates form, which help dissipate energy and slow crack growth.

Different microstructures, such as duplex, fine equiaxed, and lamellar, offer unique benefits. Duplex structures provide creep strength, fine equiaxed structures enhance tensile strength and fatigue resistance, and lamellar structures improve impact and fracture toughness.

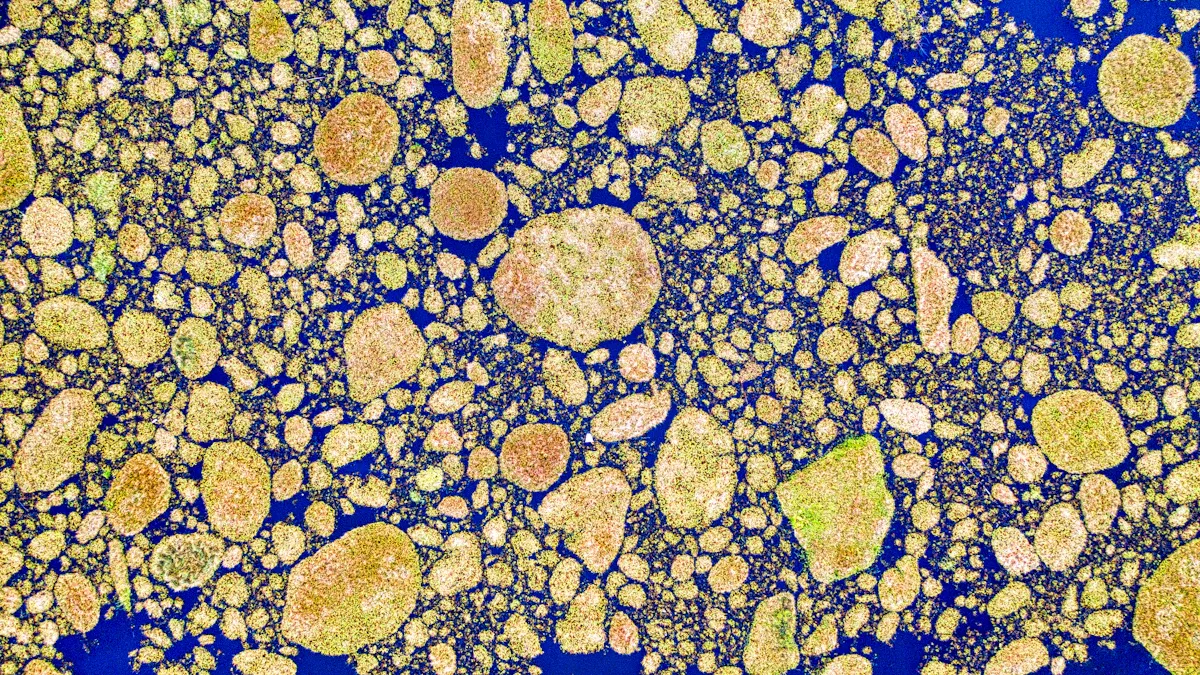

Microstructure Changes

Heat treatment transforms the microstructure of titanium alloys by altering phase composition, grain size, and morphology. Heating above the beta transus temperature leads to complete transformation to beta phase grains, which grow with time and temperature. Rapid cooling produces finer alpha structures, while slower cooling results in coarser grains. The choice of cooling rate and aging temperature determines the final balance of alpha and beta phases, directly affecting mechanical properties.

- Rapid cooling, such as water quenching, promotes martensite formation and increases hardness.

- Slower cooling allows for coarser alpha grains and improved toughness.

- Various microstructures, including lamellar, equiaxed, and Widmanstätten, can be achieved by adjusting heat treatment parameters.

These microstructural changes enable engineers to tailor titanium alloys for specific performance requirements.

Corrosion Resistance

Titanium alloys display impressive corrosion resistance, making them valuable in aerospace, medical, and chemical industries. Heat treatment processes play a critical role in shaping this property. Engineers observe that the microstructure and phase composition after heat treatment determine the alloy’s ability to form and maintain protective oxide layers.

Moderate heat treatment, such as heating additively manufactured TC4 alloy at 800°C for one to four hours, decomposes the metastable α′ phase into a stable α+β biphasic structure. This transformation raises the self-corrosion potential and stabilizes the oxide layer, improving electrochemical performance. Excessive heat treatment, especially at 940°C, causes grain coarsening. Larger grains increase the self-corrosion current density and passivation current density, which degrades corrosion resistance. The following table summarizes these effects:

| Heat Treatment Condition | Microstructure Change | Corrosion Resistance Effect |

|---|---|---|

| Moderate (800°C, 1–4h) | α′ → α+β biphasic | Improved; higher self-corrosion potential |

| Excessive (940°C) | Grain coarsening | Degraded; increased corrosion current |

| Untreated | Stable oxide layer formation | Superior general corrosion resistance |

| Quenched | Unstable oxide, surface degradation | Most susceptible to corrosion |

| Annealed | Grain boundary degradation | Vulnerable under harsh conditions |

Untreated B265 titanium alloy forms stable oxide layers, which reduce vulnerability to corrosion and metastable pitting. Quenched alloys show significant surface degradation, especially in high electrolyte concentrations and elevated temperatures. Annealed alloys may degrade along grain boundaries under harsh conditions.

Several heat treatment processes enhance corrosion resistance by modifying the alloy’s microstructure and surface properties:

- Solution treatment followed by quenching dissolves alloying constituents and rapidly cools the material, improving corrosion properties.

- Surface treatments create crystalline titanium oxide layers, increasing oxidation and corrosion resistance.

- Aging treatment adjusts phase precipitation, influencing β phase content and erosion resistance.

- Annealing relieves residual stresses and increases ductility, indirectly supporting corrosion resistance.

- Thermochemical treatments combine thermal and chemical effects to modify surface layers.

Post heat treatment of additively manufactured Ti6Al4V reduces the non-equilibrium martensitic α′ phase and promotes β phase formation. These changes relieve residual stresses and elevate corrosion resistance to levels comparable with conventional wrought titanium alloys.

Tip: Selecting the right heat treatment process and controlling temperature and duration are essential for maximizing corrosion resistance in titanium alloys. Engineers should tailor treatments to the alloy’s composition and intended service environment for optimal results.

Alloy Composition and Titanium Alloy Heat Treatment Processes: What to Know

Alpha Alloys

Alpha titanium alloys contain elements such as aluminum and oxygen, which stabilize the alpha phase and raise the alpha-to-beta transformation temperature. These alloys resist transformation to the beta phase even at elevated temperatures. Engineers select heat treatment processes like annealing and stress relieving for alpha alloys, as solution treatment and aging do not significantly increase strength. The microstructure remains stable, offering good creep resistance and weldability. Alpha alloys are often used in applications requiring high corrosion resistance and stability at elevated temperatures.

| Heat Treatment Process | Temperature Range | Microstructural Evolution | Mechanical Outcomes |

|---|---|---|---|

| Annealing below β-transus | 800–900 °C | Martensite transforms into lamellar α+β; α phase thickens and becomes globular | Balanced strength and ductility (elongation ~12.5%, UTS ~1100 MPa) |

| Annealing near β-transus | ~940 °C | Lamellar α+β microstructure forms | High strength–ductility matching |

| Above β-transus | >β-transus | Enhanced fracture toughness | Improved toughness and strength |

Engineers choose annealing temperatures based on alloy composition to achieve the desired balance of ductility and strength.

Alpha-Beta Alloys

Alpha-beta alloys, such as Ti-6Al-4V, contain both alpha and beta stabilizers. Alloying elements like vanadium and molybdenum lower the transformation temperature, allowing the beta phase to exist at room temperature. These alloys respond well to solution treatment and aging, which refine the microstructure and enhance mechanical properties.

- Solution treatment followed by quenching produces martensitic phases, increasing initial strength.

- Aging causes precipitation within the beta phase, further strengthening the alloy.

- Overaging leads to coarsening of the microstructure, reducing both strength and ductility.

- Engineers can tailor yield strength and ultimate tensile strength by adjusting heat treatment parameters.

Alpha-beta alloys offer a flexible combination of strength and toughness, making them suitable for aerospace and biomedical applications. The presence of both phases allows for more precise property adjustment compared to single-phase alloys.

Beta Alloys

Beta titanium alloys contain high concentrations of beta stabilizers, such as niobium and iron, which retain the beta phase at room temperature. These alloys require unique heat treatment cycles to optimize mechanical properties. Engineers often use solution treatment and aging to control alpha phase precipitation and strengthen the alloy.

| Heat Treatment Cycle | Temperature Range and Process | Resulting Microstructure |

|---|---|---|

| Duplex Anneal | Solution treat 50–75°C below beta transus, air cool, age at 540–675°C | Primary alpha plus Widmanstätten alpha-beta regions |

| Solution Treat and Age | ~40°C below beta transus, water quench, age at 535–675°C | Primary alpha plus tempered alpha prime or beta-alpha mixture |

| Beta Anneal | ~15°C above beta transus, air cool, stabilize at 650–760°C | Widmanstätten alpha-beta colony microstructure |

| Beta Quench | ~15°C above beta transus, water quench, temper at 650–760°C | Tempered alpha prime |

Beta alloys respond strongly to aging, with yield strength exceeding 1200 MPa after cold working and direct aging. Engineers must carefully control alpha phase precipitation after cooling to achieve the desired properties. Post-weld aging is essential to restore strength after welding.

The specific alloy composition guides the selection of Titanium Alloy Heat Treatment Processes: What to Know, ensuring the final product meets performance requirements.

Alloys Not Suitable for Strengthening

Engineers often encounter titanium alloys that do not respond to heat treatment for strengthening. These alloys, known as α titanium alloys, possess a unique structure that limits their ability to gain strength through thermal processes. The matrix of α titanium alloys consists of a single hexagonal close-packed (HCP) phase. This structure remains stable during heating and cooling cycles, preventing significant changes in mechanical properties.

Key characteristics of α titanium alloys include:

- Single-phase HCP matrix structure

- Strong oxidation resistance

- Reliable high-temperature performance, suitable for long-term use at 500°C

- Low strength at room temperature

- Inability to be strengthened by heat treatment

The absence of phase transformation during heat treatment means that α titanium alloys retain their original microstructure. Engineers cannot induce precipitation or martensitic transformations, which are necessary for increasing strength in other alloy types. As a result, these alloys maintain consistent properties regardless of the heat treatment process applied.

| Alloy Type | Typical Grades | Matrix Structure | Heat Treatment Response | Notable Properties |

|---|---|---|---|---|

| α Titanium | TA7, TA8 | Single-phase HCP | No strengthening | High oxidation resistance, stable at high temperatures |

Applications for α titanium alloys focus on environments where oxidation resistance and thermal stability matter more than strength. Aerospace and chemical processing industries value these alloys for their ability to withstand harsh conditions without degradation. Engineers select α titanium alloys when the design prioritizes durability over mechanical strength.

Note: When choosing titanium alloys for components that require increased strength, engineers should avoid α titanium grades such as TA7 and TA8. These alloys offer excellent resistance to oxidation and high temperatures but cannot benefit from heat treatment strengthening.

Key Controls in Titanium Alloy Heat Treatment Processes: What to Know

Temperature and Time Control

Engineers recognize that precise temperature and time control forms the foundation of successful titanium alloy heat treatment. Each process demands strict adherence to recommended ranges to achieve optimal mechanical properties and microstructural stability. For Grade 5 (Ti6Al4V), annealing typically occurs between 700°C and 870°C for 15 to 60 minutes, followed by air cooling. Stress-relief annealing requires lower temperatures, from 480°C to 650°C, with longer durations up to 240 minutes. Solution treatment above the beta transus temperature, maintained for at least 30 minutes, ensures complete phase transformation. Avoiding furnace cooling after solution treatment prevents excessive grain growth and defects. The following table summarizes critical controls:

| Heat Treatment Process | Temperature Range (°C) | Time Duration | Cooling Method |

|---|---|---|---|

| Annealing | 700 – 870 | 15 – 60 minutes | Air cooling or slower |

| Stress-relief Annealing | 480 – 650 | 60 – 240 minutes | Air or inert gas cooling |

| Recrystallization Annealing | 450 – 650 | Variable | Air or inert gas cooling |

| Quench Aging | 480 – 690 | 2 – 8 hours | Air or inert gas cooling |

Engineers must monitor temperature fluctuations and cycle times closely. Variations in alloy composition may require adjustments, emphasizing the importance of equipment calibration and maintenance.

Atmosphere: Vacuum and Inert Gas

Titanium alloys exhibit high chemical reactivity at elevated temperatures. During heat treatment, exposure to atmospheric gases such as oxygen, carbon, and hydrogen can degrade alloy properties. Engineers use vacuum furnaces or argon-protective atmospheres to prevent contamination. Maintaining vacuum pressure at or below 2×10⁻³ Pa avoids surface corrosion. Argon gas purity must exceed 99.99%, with some standards requiring 99.999% to eliminate reactions with titanium. The choice of cooling gas is critical; argon prevents nitride formation, which would otherwise compromise mechanical integrity. After heat treatment, oxide films may form and require removal to maintain surface quality.

| Atmosphere Type | Required Purity/Pressure | Purpose |

|---|---|---|

| Vacuum | ≤ 2×10⁻³ Pa | Prevents oxidation/corrosion |

| Argon (Inert) | ≥ 99.99% purity | Prevents nitride/oxide formation |

Preventing Embrittlement and Hydrogen Absorption

Hydrogen embrittlement poses a significant risk during titanium alloy heat treatment. Engineers implement several best practices to minimize hydrogen absorption and maintain ductility:

- Minimize contact with atomic hydrogen sources in corrosive environments.

- Control cathodic protection to avoid hydrogen liberation at the metal surface.

- Allow hydrogen to escape during heat treatment by managing furnace atmosphere and cooling rates.

- Use thermal baking procedures post-processing to enable hydrogen desorption.

- Employ welding practices with low heat input and perform welding in inert gas atmospheres.

- Optimize welding parameters to reduce heat-affected zones and residual stresses.

- Select materials and surface treatments that resist hydrogen ingress.

- Monitor environmental conditions and hydrogen levels regularly.

Microstructural control through heat treatment reduces hydrogen trapping sites, especially at α/β phase boundaries. Surface roughness reduction and thermal treatments further limit hydrogen absorption, enhancing resistance to embrittlement.

Controlled Heating and Cooling Rates

Engineers recognize that precise control of heating and cooling rates is essential during titanium alloy heat treatment. The rate at which temperature changes directly influences the alloy’s microstructure and, ultimately, its mechanical properties. Rapid heating can cause uneven temperature distribution, leading to thermal gradients and internal stresses. Slow, uniform heating allows the entire component to reach the target temperature, minimizing the risk of distortion or cracking.

Key reasons for controlling heating and cooling rates:

- Microstructure Optimization: Controlled rates help form the desired balance of alpha and beta phases. Fast cooling, such as water quenching, can trap metastable phases like martensite, increasing hardness but reducing ductility. Slow cooling encourages the growth of equilibrium phases, improving toughness.

- Defect Prevention: Sudden temperature changes may cause warping, residual stress, or even microcracking. Uniform rates reduce these risks.

- Dimensional Stability: Gradual heating and cooling maintain part geometry, which is critical for aerospace and medical components.

| Heating/Cooling Rate | Typical Application | Microstructural Effect |

|---|---|---|

| Rapid (quenching) | Solution treatment, hardening | Fine martensitic or alpha prime formation |

| Moderate (air cool) | Annealing, stress relief | Balanced alpha/beta phase distribution |

| Slow (furnace cool) | Stress relief, annealing | Coarse grains, improved ductility |

Tip: Engineers should always follow recommended heating and cooling profiles for each titanium alloy grade. Deviations can lead to unpredictable properties and potential failures.

Modern heat treatment furnaces use programmable controllers to manage temperature ramps and hold times. These systems ensure repeatability and quality. For critical parts, engineers often monitor temperature with multiple thermocouples to verify uniformity throughout the load.

Careful control of heating and cooling rates remains a cornerstone of successful titanium alloy processing. This attention to detail ensures that each component meets stringent performance and reliability standards.

Practical Tips for Titanium Alloy Heat Treatment Processes: What to Know

Process Selection Guidelines

Engineers should match the heat treatment process to the alloy type and the intended application. They start by reviewing the alloy’s composition and mechanical requirements. For aerospace parts, they often select solution treatment and aging to maximize strength and fatigue resistance. Medical implants may require stress relieving or annealing to ensure biocompatibility and ductility. Engineers also consider part geometry and thickness, as thicker sections may need slower heating and cooling rates to avoid thermal gradients. Consulting technical standards, such as ASTM or AMS, helps ensure compliance with industry requirements.

Tip: Always verify the recommended temperature ranges and holding times for each titanium alloy grade before starting the process.

Avoiding Common Pitfalls

Many issues can arise during Titanium Alloy Heat Treatment Processes: What to Know. Overheating may cause grain growth, which reduces toughness. Rapid temperature changes can introduce residual stresses or even cracks. Exposure to air at high temperatures leads to surface contamination and embrittlement. Engineers prevent these problems by using controlled atmospheres, such as vacuum or high-purity argon, and by following precise heating and cooling profiles. They also avoid overaging, which can lower both strength and ductility.

- Monitor furnace calibration regularly.

- Use clean handling procedures to prevent contamination.

- Avoid excessive soak times that may degrade microstructure.

Quality Assurance and Testing

Quality assurance ensures that each component meets strict performance standards. Engineers use several methods after heat treatment:

- Hardness testing, such as Rockwell or Brinell, checks resistance to deformation.

- Non-destructive testing (NDT), including ultrasonic and dye penetrant inspections, detects internal and surface flaws.

- Chemical analysis, like X-ray fluorescence, verifies alloy composition.

- Fatigue and corrosion testing assess long-term durability.

- Dimensional inspection with coordinate measuring machines (CMM) confirms accuracy.

| Testing Category | Methods/Procedures | Purpose |

|---|---|---|

| Material Certification | Mill Test Reports, ASTM/AMS/ISO compliance | Verify composition and origin |

| Non-Destructive Testing (NDT) | Ultrasonic, XRF, Dye Penetrant | Detect flaws and verify alloy composition |

| Mechanical & Performance Testing | Tensile, Hardness, Fatigue, Corrosion | Confirm strength and durability |

| Dimensional Inspection | CMM, Laser Scanners | Ensure dimensional accuracy and surface quality |

| Contamination Prevention | Cleanroom handling, strict procedures | Maintain purity for critical applications |

Note: Customer-specific quality plans may require additional lot-by-lot testing, especially for aerospace and medical components.

- Engineers gain reliable performance from titanium alloys by mastering heat treatment processes.

- Careful selection and precise control of each step prevent defects and ensure targeted properties.

- Technical standards provide essential guidance for complex projects.

- Experienced professionals offer valuable insights for challenging applications.

For advanced knowledge, readers should explore industry resources and consult experts in titanium metallurgy. Continuous learning supports innovation and quality in every titanium alloy component.

FAQ

What is the main purpose of heat treating titanium alloys?

Heat treatment improves mechanical properties. Engineers use it to increase strength, ductility, and toughness. The process also relieves internal stresses and enhances corrosion resistance. Each treatment targets specific performance requirements for aerospace, medical, or industrial applications.

Can all titanium alloys be strengthened by heat treatment?

Not all titanium alloys respond to strengthening. Alpha titanium alloys, such as TA7 and TA8, maintain a stable structure during heat treatment. These alloys resist oxidation and perform well at high temperatures, but they do not gain strength from thermal processing.

Why do engineers use vacuum or inert gas atmospheres during heat treatment?

Titanium reacts with oxygen, nitrogen, and hydrogen at high temperatures. Engineers use vacuum or high-purity argon atmospheres to prevent contamination. This control maintains surface quality and mechanical integrity, especially for critical aerospace and medical components.

How does cooling rate affect titanium alloy properties?

Cooling rate determines microstructure. Rapid cooling, such as water quenching, increases hardness but reduces ductility. Slow cooling produces coarser grains and improves toughness. Engineers select cooling rates based on the desired balance of strength and flexibility.

What quality checks follow titanium alloy heat treatment?

Engineers perform hardness tests, non-destructive inspections, and chemical analyses. Dimensional checks confirm accuracy. These procedures ensure that each component meets strict standards for strength, durability, and reliability.