3D printed bikes have evolved from simple concepts into performance powerhouses that dominate the cycling world. Pinarello launched the Bolide F HR 3D in October 2022 and claimed it was the world’s fastest 3D printed bicycle. Filippo Ganna proved this claim by breaking the Hour record on this bike, reaching an astounding 56.792 kilometers.

Complete 3D printed bicycle frames make headlines, yet this technology has revolutionized the entire cycling ecosystem. The industry is welcoming additive manufacturing rapidly through innovations like the Mythos Elix stem, the world’s first commercially available 3D printed stem. Lightweight 3D printed bicycle parts offer unmatched customization possibilities. The technology creates shapes and features that traditional carbon fiber techniques cannot replicate. It also reduces material waste to less than 10% when working with expensive materials like titanium.

Professional athletes and high-end manufacturers no longer hold exclusive rights to this technology. The urban-focused Shadow M1 electric bike delivers up to 100km of range. Specialized saddles like the ultralight Joyseat weigh between 170-210 grams. These examples show how 3D printed cycling components are now available to more riders. This piece explores twelve ground 3D printed bike innovations that deliver measurable performance benefits and demonstrate how this technology shapes what a world of cycling looks like.

Pinarello Bolide F HR 3D

Pinarello changed track cycling forever with their 3D printed Bolide F HR 3D. The bike was originally designed for Filippo Ganna’s hour record attempt where he rode an amazing 56.792 kilometers [2]. This frame shows how far bicycle manufacturing technology has come by combining state-of-the-art materials with design breakthroughs.

Key features of Bolide F HR 3D

The Bolide F HR 3D frame and fork employ Scalmalloy, an aerospace-grade alloy created specifically for 3D printing that combines scandium, aluminum, and magnesium. This strong material lets designers create shapes that would be impossible to make using traditional methods.

The frame features a revolutionary AirStream Technology that takes inspiration from humpback whales. The tubercles (protrusions) built into the seat tube and seat post design create streamwise vortices between the bumps. This makes the airflow stay attached and move more smoothly. The seat tube and seat post make up almost 40% of the total frame and fork drag, so this breakthrough improves aerodynamic performance by a lot.

The frame has optimized AirFoil sections that take advantage of UCI’s removal of the 3:1 rule. Then, Pinarello made the bottom bracket narrower from 70mm to 54mm and reduced wheel hub width from 120mm to 89mm (rear) and from 100mm to 69mm (front). This smaller frontal area is a big deal as it means better aerodynamics.

Bolide F HR 3D customization options

Each Bolide F HR 3D has just five 3D-printed parts: three pieces that form the front triangle plus seat and chain stays. Builders can size these parts down to the millimeter for each rider. The bike comes in three standard frame sizes with specific geometries that Pinarello has detailed.

Bolide F HR 3D performance benefits

The biggest advantage is the frame’s exceptional aerodynamic efficiency. Through extensive Computational Fluid Dynamics testing with NablaFlow, Pinarello optimized the handlebar geometry to reduce total drag. On top of that, the frame has narrow forks and seat stays that weigh less without hurting aerodynamic performance.

The Bolide F HR 3D follows all UCI rules and passes ISO4210 standards despite its unique design. This means riders can use this innovative 3D printed bicycle frame legally in sanctioned events.

Bolide F HR 3D pricing & availability

Cyclists who want to ride this revolutionary 3D printed bike technology will need to spend €28,750 (about £24,600) before VAT. Teams and individual riders can buy the frame right now. They’ll get the same technology that helped Ganna break the record.

Pinarello also sells a carbon fiber version (Bolide HR C) for €12,500 (about £10,700). This option gives riders similar performance at a lower price point.

Moots 3D Printed Dropouts

Moots makes use of 3D printing technology to solve bike frame arrangement challenges with their innovative titanium dropouts. These 3D printed dropouts completely reimagine how bike manufacturers can make critical components. The company spent a year developing a component that tackles multiple engineering challenges at once.

Key features of Moots dropouts

The Moots 3D printed dropouts use 6/4 titanium alloy (6% aluminum, 4% vanadium, 90% titanium) – an ultra-hard, stiff material that works great for 3D printing applications. The company’s engineers designed the system as a unified “built as one” component. This combines the dropout and brake mounts into a single piece instead of separate parts that need arrangement during assembly.

The manufacturing process builds each dropout by laying down 60-micron-thick layers of titanium powder in an argon-filled chamber. Computer-controlled lasers then fuse these layers precisely. This creates hollow internal structures that manufacturers couldn’t make through regular methods.

The built-in seatstay landing sits above the axle. This design gives enough clearance for brakes on frames of every size. Such careful engineering creates consistent performance in all Moots’ disk-equipped road, cross, and gravel bikes.

Moots dropout customization options

The 3D printing process lets Moots add custom internal features like hollow structures and internal tubes for electronic shifting, wire routing. This way of manufacturing allows precise customization without weakening the structure.

Regular machined components need a 2.4-pound billet of titanium per side to create similar structures. The 3D printed design matches this strength but weighs much less. This opens up customization options that weren’t possible with traditional manufacturing.

Moots dropout performance benefits

These dropouts provide exceptional arrangement precision – crucial for flat-mount brake systems. Even tiny misalignments can affect braking performance. The integrated design keeps brake calipers, rotors, and axles perfectly arranged throughout the frame’s life.

Production becomes simpler with the unified dropout design. Moots uses a single setup when tacking frames. This creates better consistency than traditional methods that need multiple jigging and welding steps. The rear wheel stays perfectly centered, and brake components are arranged flawlessly.

The environmental benefits are significant, too. Traditional machining wastes about 85% of materials. The 3D printing approach wastes less than 10%. In spite of that, these printed parts match solid billet titanium’s strength while weighing less, thanks to their hollow design.

Superstrata Carbon Fiber Bike

Silicon Valley’s Superstrata brings a fresh approach to bicycle manufacturing. Their 3D printed carbon fiber bikes expand design possibilities and offer custom options like never before.

Key features of Superstrata

Superstrata’s frame stands out with its unibody construction. The frame is 3D printed in one continuous pass of carbon fiber thermoplastic composite. Traditional carbon fiber frames need dozens of parts glued and bolted together. But Superstrata’s frame eliminates joints and adhesives, which creates strength throughout the structure.

The frame employs industrial-grade thermoplastic carbon fiber composite. This material gives exceptional resistance to impacts and needs less energy to manufacture compared to traditional carbon-resin builds. The thermoplastic material is easier to recycle—a big environmental plus over standard carbon frames.

The company offers two models—Terra (standard bicycle) and Ion (e-bicycle). Both come with built-in data and power wiring in the frame. This allows riders to add electronic upgrades like lights, power meters, and anti-theft devices.

Superstrata customization options

The customization possibilities are remarkable, with over 500,000 different configurations. Each frame adapts to the rider’s specific measurements. Height, weight, arm and leg lengths, riding positions, and stiffness levels can all be adjusted. This makes these bikes perfect for cyclists who don’t fit standard frame sizes, such as adults under 5’2″.

Riders can choose their preferred handlebar styles (racing, street, gravel, or touring), wheel materials (metal or carbon fiber), and colors. Premium paint options that look like starry skies or aurora borealis are also available.

Superstrata performance benefits

The e-bike weighs just 11kg—8kg lighter than similar e-bikes. A lighter bike needs less power to run. When mass drops by 10%, the range can increase up to 10%.

The Ion model packs a 252Wh battery that runs up to 60 miles. Its 250-watt motor reaches speeds of 20mph. The one-piece frame construction eliminates weak points and gives a safe, firm ride.

Superstrata pricing & availability

The Superstrata Terra costs USD 2799.00, while the Ion e-bike sells for USD 3999.00. These prices put Superstrata between budget bikes and high-end carbon fiber models that cost over USD 12,000. Custom options change the final price, and premium paint finishes add USD 1250.00.

Mythos Elix Stem

The skeletal-looking Mythos Elix stem shows a radical alteration in bicycle component design. This stem demonstrates what happens when aerospace-grade materials blend with advanced manufacturing techniques. Dimitris Katsanis—the engineering mind behind British Cycling and Team Sky’s equipment—created this component to show how 3D printing can revolutionize even the most crucial bicycle parts.

Key features of Elix Stem

Selective Laser Melting (SLM) produces the Elix stem through a sophisticated additive manufacturing process. The process fuses metallic powders layer by layer with precision. Mythos uses Scalmalloy instead of traditional aluminum. Airbus developed this advanced alloy for aerospace applications by combining scandium, aluminum, magnesium, manganese, and zirconium. Engineers call it one of the strongest aluminum alloys for additive manufacturing.

The Elix comes in lengths from 100mm to 130mm with 10mm steps and a +/-8° angle. It features titanium M5 hardware and a 31.8mm clamp diameter. The distinctive lattice design serves a purpose beyond esthetics. Manual topology optimization through Finite Element Analysis (FEA) simulations helped identify optimal load paths.

Elix Stem customization options

Mythos makes custom ELIX stems on request, though standard sizes are readily available. Cyclists can pick from silver, gloss black, or denim black finishes. The stem works with both external and internal cable routing systems. It’s compatible with FSA’s ACR and Deda’s DCR integrated cockpit systems.

Elix Stem performance benefits

The Elix’s striking looks come with real performance advantages. Through constant design improvements, Mythos created a stem that’s 15% torsionally stiffer than similar alloy stems. It maintains similar bending stiffness, which means better power transfer during sprints without losing comfort on rough roads.

Quality control remains rigorous for every production run. Each batch of 54 stems has four dedicated testing units and a test bar kept for future reference. The stems meet ISO 4210-5 fatigue testing standards, which ensures safety despite their skeletal appearance.

Elix Stem pricing & availability

The Elix costs £500 (about $650), placing it among premium bicycle components. Cyclists worldwide have embraced this stem, with strong sales in Australia, Singapore, the United States, and beyond. International shipping runs £50 per order, and customers pay duties and taxes upon delivery. Each stem comes backed by a two-year limited warranty.

SRAM Prototype Cranks

SRAM and Autodesk have joined forces to create AI-optimized bicycle components at their Generative Design Field Lab in Chicago. The prototype cranks show a complete transformation from traditional bicycle component design. AI technology now shapes optimal forms based on real-life cycling forces.

Key features of SRAM cranks

SRAM engineers create these prototype cranks through a collaborative process. They set simple constraints with a standard direct mount chainring interface and DUB bottom bracket at one end, plus a pedal spindle at the other. The cranks showcase an organic lattice structure that removes unnecessary material while keeping critical load-bearing pathways intact.

The company developed two different manufacturing methods: CNC-machined aluminum prototypes and 3D-printed sintered titanium versions. The titanium models use selective laser sintering technology. Powerful lasers compact titanium powder layer by layer at temperatures just below the liquefaction point. SRAM produced nine complete pairs of crank arms in one batch with this method.

SRAM crank customization options

These prototypes create a foundation for future customization possibilities. The manufacturing starts with radial support structures that build up into the complete component. CNC machining then perfects both the pedal interface and BB/chainring interface for precise fitment.

Autodesk’s cloud-based Fusion 360 platform hosts the entire design process. Engineering teams can work together remotely. This setup allows quick iterations through different design constraints and load parameters.

SRAM crank performance benefits

Test data shows these generative design prototype cranks handle up to 10g of force. This makes them perfect for high-performance applications. The titanium versions are twice as strong and 20% lighter than traditional manufacturing methods.

The project goes beyond immediate performance improvements. It serves as a testing ground for SRAM’s future component development. Will King, Senior Design Engineer at SRAM, explains, “This helps us get to the finish line faster and more educated—to see where material needs to be, and where it can be removed”. The knowledge gained shapes SRAM’s approach to structural components across its product line.

These exact prototypes might never reach retail shelves. However, the technological breakthroughs from this collaboration continue to influence bicycle component evolution.

Silca 3D Printed Accessories

Silca creates amazing 3D printed bicycle components for cycling enthusiasts. The company makes titanium parts more available through additive manufacturing. Their breakthroughs show how even the smallest components can benefit from advanced manufacturing methods.

Key features of Silca accessories

The company’s lineup includes 3D printed titanium tools made from hardened 6/4 titanium (6% aluminum, 4% vanadium, 90% titanium). Their titanium chain whip weighs just 80g and uses a TiN YBN 11-speed chain with internal spiral rifle reinforcements. These reinforcements draw inspiration from Columbus SLX tubing. The dual-spline titanium lock ring tool weighs only 45g and works with both Shimano/SRAM and Campagnolo cassettes. This makes it much lighter than traditional tools.

The Mensola and Chisela computer mounts feature stressed skin designs that remove material from low-stress areas. These mounts are 15% lighter and 12 times stronger than other options in the market. The titanium derailleur hangers provide 5-7x more stiffness than regular aluminum hangers and save 2-6g in weight.

Silca customization options

Customers can add custom engraving to most Silca products for an extra USD 25.00. The company’s team holds over 30 patents across Zipp and Silca brands and offers custom engineering services. Their Design for Additive Manufacturing (DFAM) service includes thermal analysis that cuts support material by up to 60%.

Silca performance benefits

These products excel at reducing weight without compromising strength. The titanium machinist hammer weighs only 160g but packs 125g of stainless steel shot in its head for impact energy. The titanium derailleur hangers solve a big problem with electronic drivetrains. Standard aluminum hangers flex up to 4 degrees during shifts, but Silca’s titanium versions stay much more rigid.

Silca pricing & availability

Each titanium tool costs USD 150.00, or USD 175.00 with custom engraving. The complete three-piece set with a chain whip, lock ring tool, and hammer sells for USD 399.00, or USD 425.00 with engraving. Titanium cleats cost USD 85.00, though you might find them for as low as USD 55.00 during sales. Computer mounts range from USD 175.00-180.00 based on model and setup. The company manufactures all products on Renishaw AM500Q machines in the USA and typically ships within 5 days.

Raceware Custom Mounts

RaceWare, a British manufacturer, stands out in the 3D printed bicycle parts market. Their computer mounts blend practicality with custom options that show how 3D printing enhances even the smallest bike parts.

Key features of Raceware mounts

RaceWare’s 3D printed nylon mounts work perfectly with Garmin cycling computers. Their signature stem mount connects to the steerer tube and positions the computer above the stem. This design works great for mountain bikes that have shorter stems, where regular mounts just don’t work. These mounts fit many Garmin models (200/500/510/520/800/810/820/1000/1030). Some versions even let you attach GoPro cameras or front lights.

Raceware customization options

RaceWare’s online platform makes customization a breeze. Riders can pick from 11 colors or mix them to create something unique. The platform lets you add your own text with control over font size and direction. You can make text read up, down, or across. Cyclists who need specific setups can choose left or right-side mounting among other stem positions.

Raceware performance benefits

The central position makes these mounts shine. Riders can see their displays better while riding compared to handlebar mounts. The mounts hold computers securely but let you adjust angles as light changes during your ride. At 12 grams, they’re among the lightest you can buy. The secure attachment keeps computers from shaking loose or falling off in crashes. This matters a lot when you use expensive GPS units on rough trails or during races.

Posedla Joyseat Saddle

Czech company Posedla revolutionizes bicycle saddles with their Joyseat – the world’s first custom 3D-printed saddle that uses precise measurements of each rider’s anatomy.

Key features of Joyseat

Posedla’s flagship product uses Multi Jet Fusion 3D printing technology to create custom TPU (thermoplastic polyurethane) padding with 0.22mm precision. The saddle comes in three variants: Plus (nylon shell with stainless steel rails at 220g), Pro (carbon shell and rails at 165g), and Ultra (reinforced UD carbon construction at just 155g). Each saddle features a unique lattice structure that works like “micro-springs” to return energy when pedaling.

Joyseat customization options

The fitting starts with the “Smiling Butt Kit” – an impression foam that measures the rider’s sit bone width down to 1mm. Riders answer 10 questions in an online configurator about their riding style, flexibility, and priorities. Posedla’s JoyFit Algorithm uses this data to design every aspect of the saddle. Riders can choose color accents and add their nickname to personalize the saddle.

Joyseat performance benefits

The Joyseat removes pressure points by tailoring zone-specific stiffness. The main advantages are:

- Custom width from 130-170mm in 1mm steps

- The saddle lasts a lot longer than foam saddles that compress after 6,000km

Joyseat pricing & availability

Riders can get the Joyseat Plus for $349, Pro for $489, and Ultra for $549. The price includes the Smiling Butt Kit, custom saddle, and ongoing customer support.

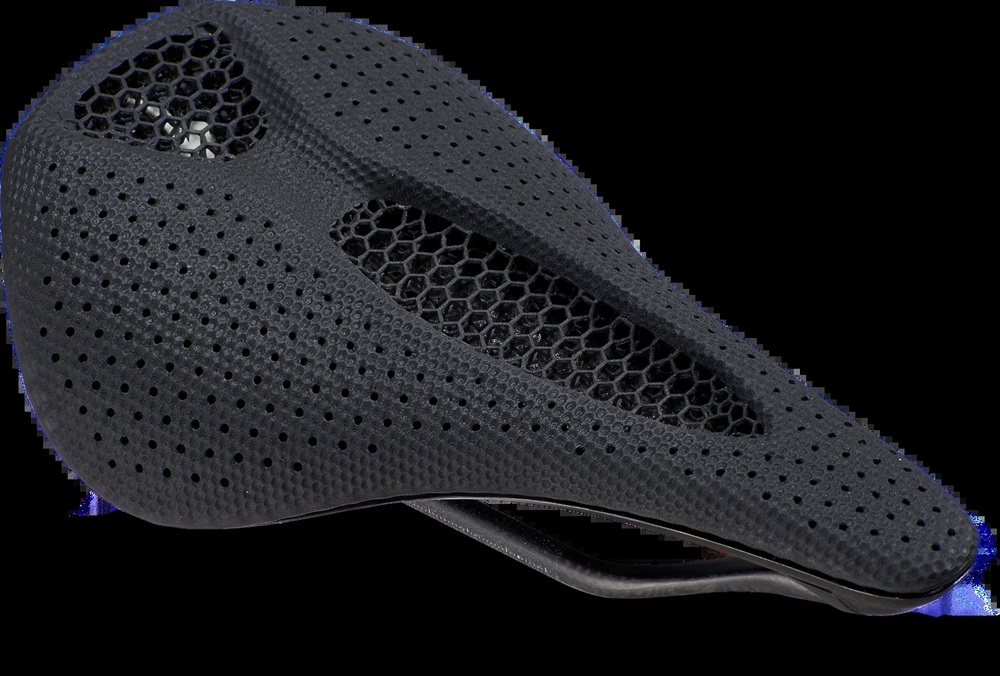

Specialized Mirror Saddle

Specialized transformed the cycling world with its Mirror saddle design. The technology uses advanced 3D printing from liquid polymer to solve one of cycling’s oldest challenges – rider discomfort.

Key features of Mirror Saddle

The Mirror saddle’s groundbreaking design includes a patent-pending matrix of 14,000 struts and 7,799 nodes that engineers can fine-tune individually. This innovative structure creates endless density variations with a single material, which traditional foam cannot achieve. The saddle comes in different models. The S-Works version has carbon fiber rails and weighs just 190g, while the Pro version features titanium rails at 245g. Both models share similar Mirror padding but use different base materials. Recent versions show Specialized’s commitment to sustainability by using reclaimed carbon fiber.

Mirror Saddle customization options

The Mirror technology gives riders multiple size choices, with some models available in 130mm and 168mm widths. Riders who love gravel and mountain biking will appreciate the Expert version’s 4-way stretch cover. This cover keeps mud and debris away from the lattice structure. Each rider can pick a model that matches their riding style and material preferences.

Mirror Saddle performance benefits

Mirror technology cuts sit bone pressure by 26% compared to standard saddles. The design creates a hammock-like support that cradles the sit bones while protecting sensitive areas. Riders experience no numbness on long rides – a huge improvement over regular saddles. The saddle’s firmness adapts to different areas: solid support under the sit bones but soft where needed, which eliminates pressure points.

KAV 3D Printed Helmet

KAV Helmets, an American company, brings custom-fit head protection through their 3D printed cycling helmets. These helmets go beyond regular foam options and create precision-fit protective gear that matches each rider’s head shape.

Key features of KAV helmet

KAV helmets’ Hex Honeycomb Structure™ forms a built-in “crumple zone” that absorbs impact three times better than traditional helmets. Their PolyCarbon Composite material handles heat eight times better than standard EPS foam and cools twice as fast. The helmet earned a Virginia Tech 5-star safety rating and beats CPSC standards by 50%. The company’s made-to-order model cuts down on inventory waste.

KAV helmet customization options

The fitting process takes 108 measurements to create a perfect fit. Riders can measure using KAV’s iPhone scanning app or get a traditional fit kit with calipers. The helmets come in several colors, like Polar White, Midnight Navy, Atomic Black, Purple Haze, and more.

KAV helmet performance benefits

A custom-fit design improves aerodynamics and saves about 90 seconds over a 60km distance. The honeycomb structure compresses and shears when needed, so there’s no need for extra MIPS layers. The Air Fit Suspension System creates a “head hammock” effect that lifts the helmet off the rider’s head. This design maximizes airflow and removes pressure points.

KAV helmet pricing & availability

These helmets cost USD 300.00 and come with a 30-day money-back guarantee. KAV’s 5-year warranty beats the usual 2-year industry coverage. They replace helmets for free during warranty if you crash. Right now, you can get these helmets in the United States and Canada. KAV plans to enter European markets as they increase production.

Angel Heaven Titanium Bike

Angel Cycle Works, a Spanish manufacturer, blends traditional craftsmanship with advanced technology in their Heaven titanium bike. This versatile “hyper bike” works well as a road racer, gran fondo machine, or light gravel explorer.

Key features of Angel Heaven

The Heaven frame uses a hybrid manufacturing approach that combines manually welded tubes with 3D-printed titanium lugs. This breakthrough saves material and makes the frame about 400g lighter than standard titanium frames, weighing around 1,600g. The frame uses 3D-printed parts at crucial points to ensure better headset bearing alignment with a press-fit bottom bracket that “will never budge a micron”.

Angel Heaven customization options

The Heaven Door (HD) adapter stands out as a breakthrough that lets riders adjust their chainstay length from 400mm to 425mm. Riders can switch between 700x30mm road tires and 700x38mm gravel options. Angel also offers many style choices. Riders can pick anodization treatments or go for complete paintwork, though painted frames cost an extra €600.

Angel Heaven performance benefits

The frame puts the rider’s body “slightly above the bottom bracket,” which leads to steadier pedaling. The 3D-printed titanium parts create exact fits throughout the frame and stop flex, even in press-fit systems that usually creak.

Angel Heaven pricing & availability

Heaven comes with premium pricing – frames start at €9,600, while complete builds can reach €17,300 based on parts chosen. Small customizations like component painting add €100. Each Heaven bike becomes a unique creation built to match the rider’s exact needs.

Canyon 3D Printed Prototype

German manufacturer Canyon created a groundbreaking 3D printed mountain bike prototype that balances sustainability with performance. The concept bike, made for BIKE Magazine’s ‘Ride Green’ campaign, shows how additive manufacturing could transform bicycle production.

Key features of the Canyon prototype

The circular bicycle frame employs Selective Laser Melting (SLM) technology to combine metal’s mechanical properties with 3D printing’s design freedom. The innovative structure pairs an internal skeleton for strength with an outer protective shell. The frame and fork together weigh just 2 kg. The team printed each of the three frame sections in six hours, which proves how quick additive manufacturing can be.

Canyon customization options

The frame design has smart features like cable routing that runs smoothly through individual downtube struts. This production method creates designs that traditional manufacturing simply cannot achieve. The prototype also comes with ready-made bearing seats, a BSA threaded bottom bracket, and Boost-spaced thru-axles.

Canyon performance benefits

The fabrication method does more than look good – it cuts down material use and strategically reduces weight. The bike’s recycled aluminum powder makes it both eco-friendly and high-performing. This prototype could shape future Canyon models, even if this exact version never hits production.

Comparison Table

| Product Name | Material Used | Key Features/Technology | Weight | Price | Customization Options |

|---|---|---|---|---|---|

| Pinarello Bolide F HR 3D | Scalmalloy (aerospace-grade alloy) | AirStream Technology, 5 3D-printed parts | Not mentioned | €28,750 | 3 standard frame sizes with millimeter-perfect sizing |

| Moots 3D Printed Dropouts | 6/4 Titanium alloy | Built-as-one unified component, 60-micron layer construction | Not mentioned | Not mentioned | Custom internal features, electronic shifting wire routing |

| Superstrata Carbon Fiber | Thermoplastic carbon fiber | Unibody construction, no joints/adhesives | 11kg (e-bike) | $2,799 (Terra), $3,999 (Ion) | 500,000+ possible configurations |

| Mythos Elix Stem | Scalmalloy | Selective Laser Melting, lattice design | Not mentioned | £500 | Custom sizes available, 3 finish options |

| SRAM Prototype Cranks | Titanium/Aluminum | AI-optimized design, selective laser sintering | Not mentioned | Not mentioned | Cloud-based customization platform |

| Silca 3D Printed Accessories | 6/4 Titanium | Hardened titanium construction | 45g-160g (varies) | $150-399 | Custom engraving available |

| Raceware Custom Mounts | 3D printed nylon | Direct steerer tube mounting | 12g | Not mentioned | 11 colors, personalized text options |

| Posedla Joyseat Saddle | TPU (thermoplastic polyurethane) | Multi Jet Fusion technology | 155g-220g | $349-549 | Custom-fit based on anatomical measurements |

| Specialized Mirror Saddle | Liquid polymer | 14,000 struts, 7,799 nodes | 190g-245g | Not mentioned | Multiple sizes available |

| KAV 3D Printed Helmet | PolyCarbon Composite | Hex Honeycomb Structure | Not mentioned | $300 | 108 individual measurements, multiple colors |

| Angel Heaven Titanium | Titanium | Hybrid manufacturing, 3D-printed lugs | 1,200g (frame) | €9,600 (frame) | Adjustable geometry, custom paint options |

| Canyon 3D Printed Prototype | Recycled aluminum | SLM technology, internal skeleton design | 2kg (frame+fork) | Not mentioned | Internal cable routing options |

Conclusion

3D printing technology has changed how cycling equipment moves from design concepts to real performance boosters. Looking at twelve breakthrough components reveals a clear pattern – additive manufacturing brings real benefits to products at every price point.

Material science drives this transformation powerfully. High-end materials like Scalmalloy, thermoplastic carbon fiber composites, and titanium are the foundations of parts we couldn’t even imagine before. These materials let designers create freely while making parts as strong as or stronger than traditional ones.

The benefits show up clearly in the numbers. Silca’s titanium tools are ultralight, and Angel Heaven’s frame weighs 400g less than regular titanium frames. The improvements extend to aerodynamics too, as seen in Pinarello’s Bolide F HR 3D with its groundbreaking AirStream Technology.

Custom fit options make this technology truly special. KAV helmets use 108 different head measurements, and Posedla builds saddles for individual body shapes. 3D printing makes this level of personalization possible at a scale that traditional manufacturing never could.

The price range spans quite a gap. Superstrata sells a complete carbon fiber frame for $2,799, while serious racers might spend €28,750 on Pinarello’s record-breaking Bolide. Riders can still get started with more affordable options like Raceware mounts and Silca accessories.

Bike makers will use more 3D printing as costs drop and material choices grow. Canyon’s prototype points to a future where recycled materials combine with advanced manufacturing to create parts that work better for both riders and the environment.

The bike industry sits at an exciting crossroads where state-of-the-art technology meets practical needs. Traditional manufacturing will keep its place for mass production, but 3D printing has become a key tool in creating bike parts that perform well in real-life conditions.

Key Takeaways

3D printed bike parts have evolved from experimental concepts to performance-proven components used by professional athletes and everyday cyclists alike.

• Material Innovation Drives Performance: Aerospace-grade alloys like Scalmalloy and 6/4 titanium enable designs impossible with traditional manufacturing while maintaining superior strength-to-weight ratios.

• Customization Reaches New Heights: From KAV helmets with 108 individual measurements to Posedla saddles molded to specific anatomies, 3D printing delivers personalization at unprecedented scales.

• Weight Reduction Without Compromise: Components like Angel Heaven frames save 400g over traditional titanium while Silca tools achieve dramatic weight savings through hollow internal structures.

• Price Accessibility Spans All Budgets: Entry points exist from $12 Raceware mounts to premium €28,750 Pinarello frames, making 3D printed technology accessible across cycling disciplines.

• Proven Performance in Competition: Filippo Ganna’s hour record on the Pinarello Bolide F HR 3D demonstrates these aren’t just prototypes—they’re race-winning technologies delivering measurable advantages.

The cycling industry has embraced additive manufacturing as a bridge between cutting-edge innovation and practical application, creating components that excel in real-world riding conditions while opening new possibilities for future bicycle design.

FAQs

Q1. What are some exciting 3D-printed bike parts to look out for in 2025? Some innovative 3D printed bike parts in 2025 include the Pinarello Bolide F HR 3D frame, Moots 3D printed dropouts, Superstrata carbon fiber bikes, Mythos Elix stems, and KAV 3D printed helmets. These parts offer benefits like customization, weight reduction, and improved performance.

Q2. How does 3D printing improve bicycle component customization? 3D printing enables unprecedented levels of customization for bike parts. For example, the Posedla Joyseat saddle uses precise anatomical measurements to create a fully custom fit, while KAV helmets are tailored using 108 individual measurements of the rider’s head.

Q3. What materials are commonly used in 3D printed bicycle components? Common materials for 3D printed bike parts include aerospace-grade alloys like Scalmalloy, titanium alloys, thermoplastic carbon fiber composites, and specialized polymers. These materials offer excellent strength-to-weight ratios and allow for complex designs.

Q4. How do 3D printed bike parts compare in weight to traditional components? 3D printed bike parts often achieve significant weight reductions compared to traditional components. For instance, the Angel Heaven titanium frame is about 400g lighter than typical titanium frames, while maintaining strength and performance.

Q5. Are 3D printed bicycle components only for professional athletes? No, 3D printed bike components are available for cyclists at various levels and budgets. While some high-end parts like the Pinarello Bolide frame are used by professionals, there are more affordable options like Raceware mounts and Silca accessories that make the technology accessible to everyday cyclists.