Medical Titanium 3D Printing

GPT When considering 3D printing for titanium alloys, these benefits stand out:

Online Instant Pricing & Free DFM: With online tools providing instant quotes and free Design for Manufacturing (DFM) feedback, you’ll know your costs upfront and can optimize your design for manufacturability before production.

Rapid Prototype in as Little as 2 Days: Enjoy rapid turnaround times with prototypes ready in just two days, allowing you to quickly test designs and bring products to market faster.

Tight Tolerance Control to +/- 0.01 mm: Advanced 3D printing processes ensure precision with tolerances up to +/- 0.01 mm, guaranteeing that your designs meet strict quality requirements.

Why Is Titanium Alloy So Common in the 3D Printing Medical Industry?

Titanium alloy, particularly Ti6Al4V, has become the leading material in 3D-printed medical implants due to its unique combination of characteristics. The technology of additive manufacturing (3D printing) has significantly improved the ability to tailor orthopedic implants, aligning perfectly with the benefits of titanium alloys. Here’s why these materials are so widely used:

Characteristics of Titanium Alloy Implants:

- Biocompatibility:

- Elastic Modulus Similar to Bone:

- Strength and Flexibility:

- Corrosion Resistance:

- Non-Toxic:

- Thermal Stability:

Biocompatibility: Titanium alloy has excellent biocompatibility, promoting osseointegration (bone integration). This means that the implant becomes firmly anchored to the surrounding bone, ensuring stability and a natural fit.

Elastic Modulus Similar to Bone: The elastic modulus of 3D-printed titanium alloy is lower than that of conventional titanium, making it more similar to natural bone and reducing the risk of stress shielding. This prevents weakening of surrounding bone tissue.

Strength and Flexibility: The alloy offers a unique combination of strength and flexibility, with superior fatigue resistance, making it suitable for joint replacements and other orthopedic applications where durability and movement are key.

Corrosion Resistance: It has exceptional resistance to corrosion from bodily fluids and is insoluble in strong acids and alkalis, offering a high level of chemical stability and ensuring its longevity inside the body.

Non-Toxic: Titanium alloy is non-toxic and does not pose any significant risk of adverse reactions in the body.

Thermal Stability: Titanium alloys can maintain their high strength up to 500°C, ensuring mechanical stability.

Benefits of 3D Printing Technology in Medical Applications:

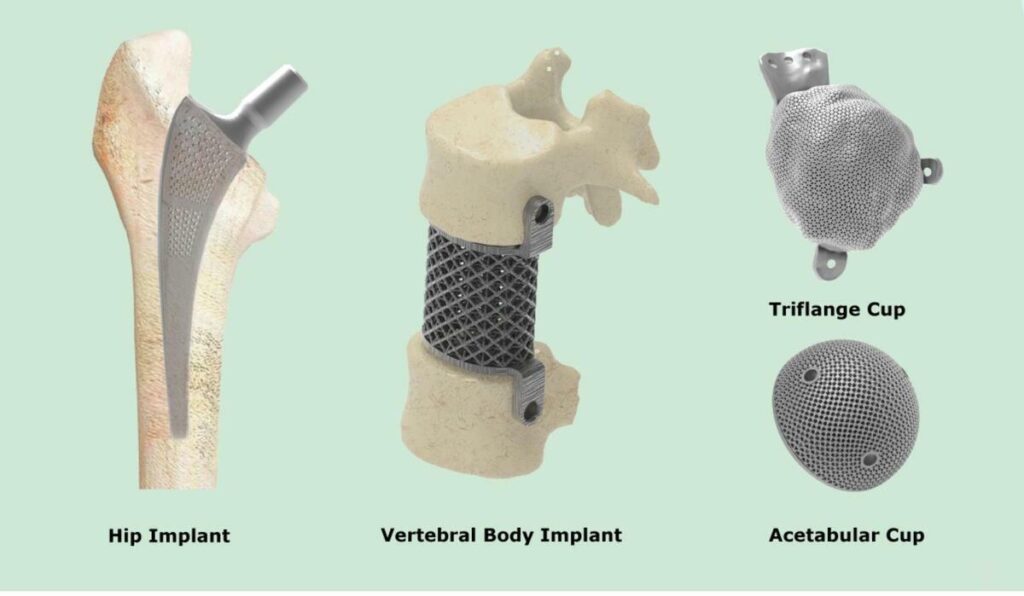

Personalized Customization: 3D printing allows for implants to be customized according to the patient’s bone structure, creating a perfect match. This leads to improved function and better integration with existing anatomy.

Lower Costs and Shorter Production Cycles: Traditional manufacturing requires casting, machining, or molds, which can be costly and time-consuming. With 3D printing, near-net-shape production minimizes waste and allows for rapid prototyping, often within 24 hours.

Complex Structures and Micro-Porous Design: 3D printing enables the creation of porous structures that mimic natural bone, enhancing bone integration and reducing the implant’s impact on surrounding tissues.

Current Applications of Titanium Alloy in 3D-Printed Implants:

Orthopedic Implants:

Such as spinal cages, joint replacements, and customized implants for complex bone structures.

Veterinary Medicine:

Helping injured animals with custom implants that restore mobility and function.

Spinal Correction:

Producing specialized implants that correct spinal deformities like scoliosis.

The continuous development of additive manufacturing, coupled with improvements in materials and technology, will likely lead to even broader and more sophisticated applications of titanium alloys in the medical field.

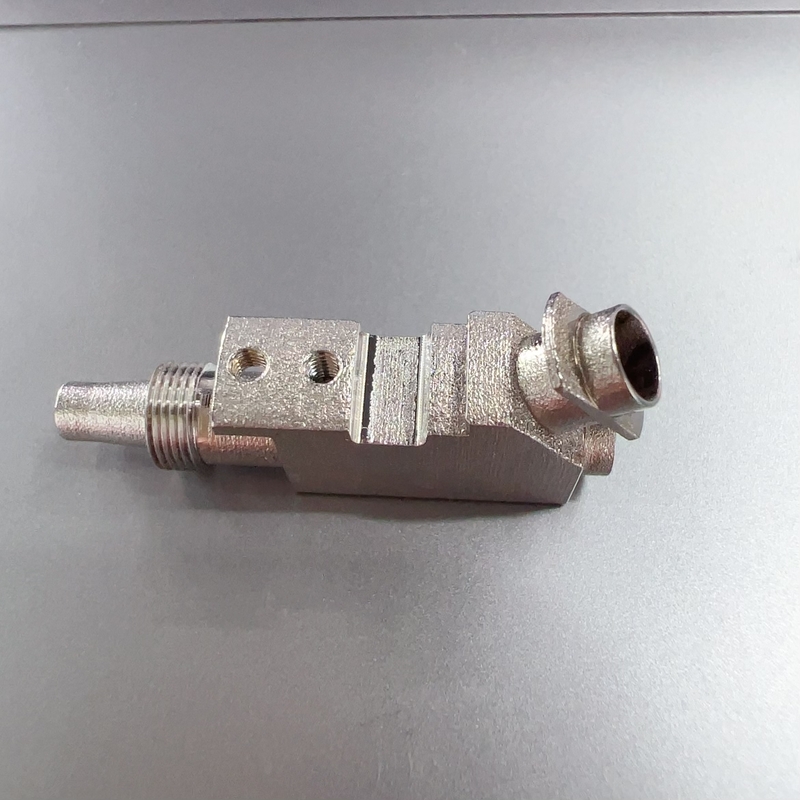

Titanium is a popular material for 3D printing, especially in the medical field, due to its biocompatibility, strength, and corrosion resistance. When it comes to endoscopic accessories, 3D printing enables the creation of custom, lightweight, and complex shapes that traditional manufacturing might struggle with.

Contact our

Related Additive Manufacturing Machine

Contact Coconutio to Start Your Business

Have a look at how some of our clients perceive our goods and services: