Manufacturing custom titanium parts often involves significant expenses. Machining titanium alloy ingots generates substantial material waste; prompt titanium swarf can account for 25% to 40% of annual ingot production. The “Buy-to-fly Ratio” for titanium frequently ranges from 10:1 to 20:1, emphasizing this material inefficiency. Furthermore, titanium’s inherent resistance to deformation and its high melting point demand greater energy input during processing. The Kroll process, for example, consumes approximately 50 kWh per kilogram. This blog explores strategic approaches to reduce cost and achieve substantial long-term savings in titanium part production.

Key Takeaways

- Choose the right titanium material. This balances performance needs with cost.

- Use advanced manufacturing methods. 3D printing and near-net shape processes save material.

- Reduce material waste. Design parts simply and recycle titanium scraps.

- Save energy in production. Optimize machine settings and use efficient equipment.

- Make post-processing faster. Automate finishing and pick smart surface treatments.

- Plan designs carefully. Use computer simulations to find problems early.

- Recycle titanium scraps. This helps lower material costs.

Optimize Material Selection to Reduce Cost

Strategic material selection has a significant impact on the overall cost of custom titanium parts. Manufacturers can achieve substantial savings by making informed choices early in the production cycle.

Strategic Material Procurement

Effective procurement strategies directly influence material costs. Businesses must consider both the quantity and the source of their titanium.

Bulk Purchasing Advantages

Purchasing titanium in larger quantities often leads to lower unit prices. Suppliers typically offer discounts for bulk orders, which can significantly reduce the cost per kilogram. This approach also minimizes shipping frequency and associated logistics expenses.

Supplier Relationship Management

Developing strong, long-term relationships with titanium suppliers provides numerous benefits. Preferred partners may offer more favorable pricing, priority access to materials, and better payment terms. These relationships also facilitate consistent quality and reliable delivery schedules.

Utilize Near-Net Shape Materials

Employing materials that closely resemble the final part geometry minimizes waste and machining time.

Benefits of Pre-Formed Stock

Pre-formed stock, such as custom extrusions or forgings, arrives closer to the desired shape. This reduces the amount of material removal required during machining. It also shortens production cycles and lowers energy consumption.

Reducing Initial Material Volume

Conventional methods for manufacturing titanium alloy components often involve extensive subtractive machining of forged billets. This process typically removes 80–90% of the original forging to achieve final part dimensions. In contrast, near-net shape (NNS) manufacturing processes require significantly less material removal. They produce geometries much closer to the final component. This leads to a reduced amount of waste material, such as machining swarf, and lower machining costs.

Choose the Right Titanium Grade

Selecting the appropriate titanium grade is crucial for balancing performance requirements with cost efficiency.

Balancing Performance and Cost

Different titanium grades offer varying properties and come at different price points. Engineers must specify a grade that meets the application’s performance demands without over-engineering the part. Over-specifying a grade can lead to unnecessary expenses.

Impact of Alloy Composition on Machinability

The alloy composition of titanium directly affects its machinability and, consequently, its processing cost.

| Titanium Grade | Relative Cost Index |

|---|---|

| Grade 2 (CP) | 1x |

| Grade 5 (Ti-6Al-4V) | 2x – 3x |

The cost differences between titanium grades like CP Grade 2 and Ti-6Al-4V (Grade 5) stem primarily from raw material costs and processing complexity. CP Grade 2 is unalloyed, making its raw material costs the lowest. It primarily consists of refined titanium sponge. Grade 5 requires the addition of alloying elements such as aluminum and vanadium, which significantly increase its base material cost. Furthermore, Grade 5 demands carefully controlled heat treatment to enhance its strength, involving heating above its Beta-transus temperature and specific cooling rates. This adds to energy, time, and equipment costs. CP grades are much simpler to process, as they do not require such complex heat treatments, contributing to their lower overall price.

Embrace Advanced Manufacturing to Reduce Cost

Advanced manufacturing techniques offer significant opportunities to reduce cost in custom titanium part production. These innovative methods address traditional challenges like material waste and extensive machining.

Additive Manufacturing (3D Printing)

Additive manufacturing, or 3D printing, revolutionizes titanium part fabrication. This technology builds parts layer by layer directly from digital designs.

Minimizing Material Waste

Additive manufacturing inherently minimizes material waste. It only uses the material necessary to form the part. Studies indicate significant environmental impact reductions compared to conventional methods. For instance, EBM-PBF can reduce environmental impacts by 5–51% compared to milling for aeronautical turbines when the milling process requires over seven times the part volume in material. This suggests a substantial reduction in material waste, as environmental impact often links directly to material usage and waste generation.

Producing Complex Geometries Efficiently

3D printing excels at creating complex geometries. Manufacturers produce intricate internal structures and optimized designs without incurring additional tooling or machining costs. This capability allows for lighter, stronger parts with fewer components.

Near-Net Shape Forging and Casting

Near-net shape (NNS) processes, such as forging and casting, produce components very close to their final dimensions. This approach significantly reduces the material requiring removal.

Reducing Machining Time

NNS parts require substantially less post-processing and machining.

- Near-net shape forging significantly reduces material waste compared to machining from basic profiles.

- For multiple parts, near-net shape savings accumulate, including ‘unseen savings’ like reduced time for reordering cutting bits, restocking cutting fluids, and recycling metal swarf.

- It increases machine time availability.

- Near-net shape forgings reduce machine time, waste chips, cutting fluids, tool wear, and delivery time.

- Despite a potentially higher initial price, reduced machining time, wear, elimination of waste, and faster delivery translate into cost savings and profit improvements.

The payoffs are astounding: less titanium, less machining, less lead time, and less inventory. These benefits give our customers increased flexibility and major cost savings.

Improving Material Properties

Forging and casting processes enhance the mechanical properties of titanium. These methods refine grain structure, improving strength and fatigue resistance in the final component.

Hybrid Manufacturing Techniques

Hybrid manufacturing combines additive and subtractive processes within a single machine or integrated workflow, leveraging the strengths of both methods.

Combining Processes for Efficiency

Hybrid additive manufacturing offers a versatile solution. It allows for the creation of unique, on-demand petrochemical fixtures from superalloy materials like titanium. Hybrid manufacturing reduces material waste and energy consumption compared to conventional methods by minimizing support structures, post-processing, or multiple setups. For titanium parts, 3D printing can be more cost-efficient than milling, turning, or casting for small and medium batches. Production costs are less dependent on component complexity. This is achieved by using a 3D printer and metal powder instead of expensive tools or specialized solutions.

Minimizing Cost Factors

Hybrid techniques effectively minimize several cost factors.

- Reduced Material Cost: Additive manufacturing allows material to be added only where needed, reducing overall material consumption.

- Reduced Subtractive Machining Work: Less material needs to be removed, decreasing the area requiring finishing.

- Time Savings: The ability to switch between additive and subtractive operations without moving the workpiece significantly reduces production time. One common technique involves additive manufacturing (3D printing) combined with CNC machining. Manufacturers use this for medical implants and structurally optimized components. 3D printing creates complex geometries; CNC machining refines critical functional areas for accuracy. These integrated processes help reduce cost and improve efficiency.

Minimize Material Waste to Reduce Cost

Minimizing material waste is a critical strategy for manufacturers to reduce cost in custom titanium part production. Titanium is an expensive material, so every effort to conserve it directly impacts the bottom line. Implementing efficient practices throughout the manufacturing process helps achieve significant savings.

Design for Manufacturability (DFM)

Design for Manufacturability (DFM) principles guide engineers to create designs that are easier and more cost-effective to produce. This approach considers manufacturing constraints early in the design phase.

Simplifying Part Geometry

Simplifying part geometry directly reduces the amount of material required. Complex shapes often necessitate more intricate machining operations, leading to increased scrap. Engineers design parts with fewer curves, simpler angles, and consistent wall thicknesses. This approach streamlines production and minimizes material removal.

Reducing Unnecessary Features

Designers often include features that are not essential for a part’s function. Eliminating these unnecessary features saves material and reduces machining time. Every removed boss, pocket, or intricate detail contributes to lower material consumption and faster production cycles.

Efficient Nesting and Layout

Efficient nesting and layout techniques maximize the use of raw material sheets or plates. This process arranges multiple part geometries on a single piece of stock to minimize gaps.

Maximizing Material Utilization

Maximizing material utilization ensures that manufacturers cut as many parts as possible from a given sheet of titanium. This directly reduces the amount of scrap material generated. High utilization rates are crucial for expensive materials like titanium.

Software-Assisted Optimization

Advanced software tools play a vital role in optimizing nesting patterns. These programs use sophisticated algorithms to arrange parts efficiently. For example, an aerospace supplier achieved a 91% material utilization rate for titanium wing components using NFP-based software. This optimization resulted in annual material cost savings of $180,000. Such software significantly enhances material efficiency.

Chip Management and Recycling

Proper management and recycling of titanium chips and scrap offer another avenue for cost reduction. Titanium scrap retains significant value.

Value of Titanium Scrap

Titanium scrap is not merely waste; it is a valuable commodity. Manufacturers can sell collected chips and offcuts to recyclers. This practice offsets some of the initial material cost. The market for recycled titanium continues to grow.

Proper Collection and Reprocessing

Effective chip management involves collecting and segregating titanium scrap properly. Contamination reduces the value of the scrap. Advanced recycling techniques, such as plasma arc melting, are reducing the price difference between recycled titanium and new, raw titanium material. This makes recycled titanium a more affordable alternative to virgin material for manufacturers. It particularly benefits sectors like aerospace and defense by lowering raw material costs and promoting sustainable practices.

Reduce Energy Consumption in Production

Manufacturers can significantly reduce energy consumption during titanium part production. This directly contributes to lower operating expenses and helps reduce cost. Implementing efficient practices across various stages of the manufacturing process yields substantial savings.

Optimize Machining Parameters

Optimizing machining parameters is crucial for energy efficiency. This involves carefully adjusting settings to achieve desired results with minimal energy input.

Balancing Speed, Feed, and Depth of Cut

Adjusting cutting speed, feed rate, and depth of cut significantly impacts energy use. Lower values for cutting speed and depth of cut, combined with higher feed rates, prove advantageous for reducing energy consumption in dry turning of Ti6Al4V. This optimization balances trade-offs between temperature, forces, and energy consumption, enhancing process stability and efficiency.

Reducing Cycle Times

Parameter optimization directly leads to shorter cycle times. A digital twin-based optimization approach resulted in significant reductions in spindle energy consumption by 11.96% and specific cutting energy by 28.24% in CNC equipment, including milling processes for titanium alloys. Furthermore, parameter optimization using an RBFNN-MOPSO algorithm achieved a 2.65% reduction in overall energy consumption during milling.

Energy-Efficient Equipment

Investing in modern, energy-efficient equipment offers long-term benefits. These machines consume less power and often provide superior performance.

Investing in Modern Machinery

Modern machinery incorporates advanced technologies that minimize energy waste. Older machines often operate with outdated motors and less efficient drive systems. Upgrading to newer models can lead to considerable energy savings over time.

Lower Power Consumption Models

Manufacturers should prioritize equipment models designed for lower power consumption. These machines often feature energy-saving modes, efficient motor designs, and optimized control systems. Selecting such models reduces the overall energy footprint of the production facility.

Advanced Cooling and Lubrication

Advanced cooling and lubrication techniques play a vital role in managing heat and extending tool life, which in turn reduces energy consumption.

Minimizing Heat Generation

Advanced cooling methods effectively minimize heat generation during machining. Through-spindle coolant, for example, reduces cutting-zone temperatures by nearly 90% compared to dry cutting. This significantly impacts temperature control. Coolant, especially when injected directly between the cutter edge and material at high pressures and volumes, reduces the coefficient of friction and overall heat production. MQL (Minimum Quantity Lubrication) conditions significantly reduce drilling torque and energy consumption by lowering frictional forces at the tool-workpiece interface.

Extending Tool Life

Advanced cooling and lubrication also extend tool life. MQL lubrication reduces the cutting tool radius increment rate and improves flank wear by 26.2% compared to dry machining. It also improves surface roughness and tool diameter reduction. Fusion’s Pure-Cut® technology, utilizing scCO2, efficiently dissipates heat at the cutting zone, reducing thermal deformation and extending tool life. Tools last up to 2x longer, leading to reduced replacement frequency and costs. This results in lower operating costs due to fewer tool changes and improved efficiency.

Streamline Post-Processing to Reduce Cost

Manufacturers can significantly reduce costs by streamlining post-processing operations for custom titanium parts. These final steps, including finishing, surface treatment, and quality control, often involve labor-intensive processes. Optimizing these stages directly impacts overall production expenses and efficiency.

Automated Finishing Processes

Automated finishing processes offer substantial advantages over traditional manual methods. They enhance efficiency and consistency.

Reducing Manual Labor Costs

Automating tasks like deburring, polishing, and grinding significantly reduces reliance on manual labor. Robotic systems perform these repetitive tasks faster and more consistently than human operators. This leads to lower labor expenditures and increased throughput.

Ensuring Consistent Quality

Automated finishing systems deliver a uniform quality across all parts. They eliminate human error and variability. This consistency reduces the need for rework or scrap due to uneven finishes, ensuring every part meets specifications.

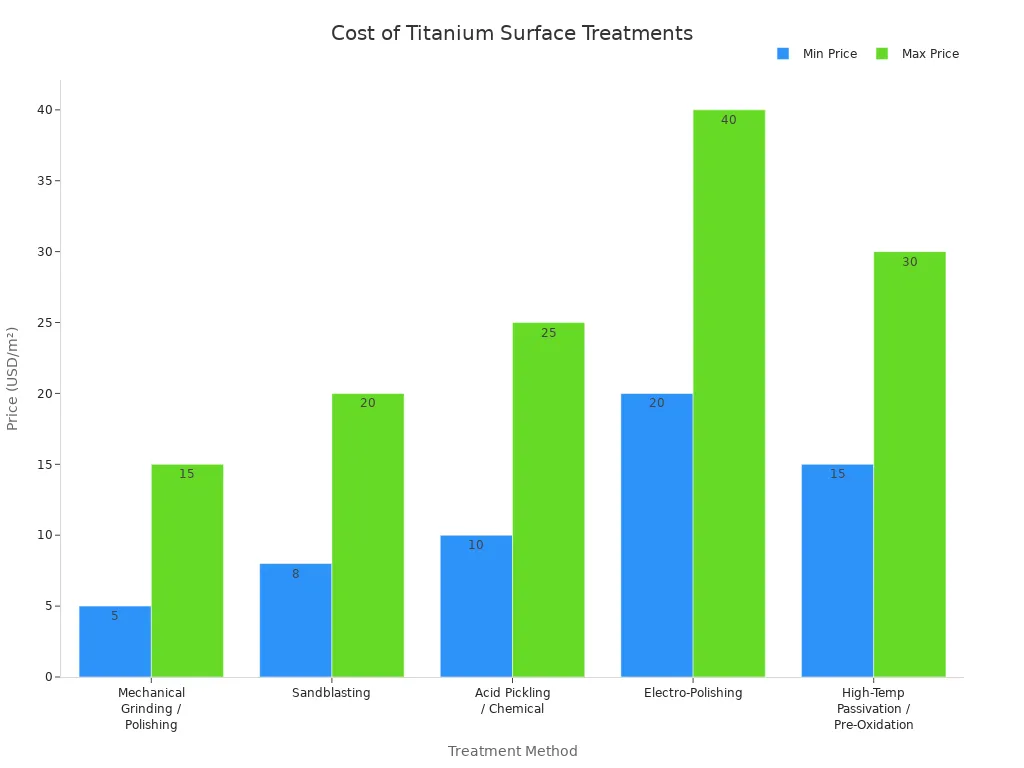

Optimized Surface Treatment

Selecting the correct surface treatment method is crucial for both performance and cost-effectiveness. Over-processing or choosing an unsuitable method adds unnecessary expense.

Selecting Cost-Effective Methods

Manufacturers must match the surface treatment to the part’s specific application requirements. Different methods offer varying levels of finish and protection at different price points.

| Treatment Method | Approx. Price (USD/m²) | Applications & Notes |

|---|---|---|

| Mechanical Grinding / Polishing | 5–15 | Basic or mid-level finish, consumer products |

| Sandblasting | 8–20 | Increases roughness for coating adhesion, industrial electrolysis |

| Acid Pickling / Chemical | 10–25 | Removes oxide scale and impurities, prepares for high-performance coatings |

| Electro-Polishing | 20–40 | Ultra-smooth, high-purity surfaces, medical implants |

| High-Temp Passivation / Pre-Oxidation | 15–30 | Boosts corrosion resistance & coating adhesion, harsh environments |

Consider these points when selecting a surface treatment:

- Match Treatment with Your Performance Goals: For basic finishing, consider mechanical polish plus acid pickling. For stronger adhesion and corrosion resistance, add sandblasting or high-temperature passivation.

- Balance Volume & Precision: Large production runs benefit from automated systems, lowering per-unit costs. Small batches or precision parts may require custom setups, increasing cost but ensuring quality.

- Communicate Your Inspection Requirements: Discuss the necessity of advanced tests (SEM, XPS) as extra testing and certification can raise the final bill.

- Check Environmental Compliance: Reliable suppliers invest in waste treatment and safety, which are often built into their quotes. Very low prices might indicate skipped environmental steps, potentially leading to quality or legal issues.

Avoiding Over-Processing

Applying treatments beyond what the application requires wastes resources. For example, a part needing only basic corrosion resistance does not require expensive electro-polishing. Engineers should specify the minimum necessary treatment to meet performance criteria.

In-Process Quality Control

Implementing quality control measures throughout the post-processing stages prevents costly errors. This proactive approach saves time and materials.

Reducing Rework and Scrap

Catching defects early in the process minimizes the need for rework. It also reduces the amount of scrapped material. Addressing issues immediately prevents them from escalating into more significant, expensive problems later.

Early Defect Detection

Integrating automated inspection systems, such as optical scanners or CMMs, allows for rapid defect detection. These systems identify flaws before further processing occurs. This ensures only compliant parts move to the next stage, saving time and resources.

Leverage Design and Prototyping to Reduce Cost

Strategic design and prototyping phases offer significant opportunities to reduce cost in custom titanium part manufacturing. Early-stage decisions profoundly impact material usage, machining time, and overall production expenses.

Virtual Prototyping and Simulation

Virtual prototyping and simulation tools allow engineers to test and refine designs digitally. This approach minimizes the need for expensive physical iterations.

Reducing Physical Prototype Iterations

Engineers use advanced software to create virtual models and simulate their performance under various conditions. This process identifies potential issues and optimizes designs before any material is cut. Consequently, manufacturers produce fewer physical prototypes, saving substantial time and material costs associated with each iteration.

Identifying Design Flaws Early

Simulation tools can detect design flaws, stress concentrations, or performance deficiencies early in the development cycle. Addressing these issues in the virtual environment prevents costly rework or part failures during later production stages. Early detection ensures a more robust and manufacturable design from the outset.

Iterative Design with Cost in Mind

An iterative design process, continuously considering cost implications, leads to more economical parts. This approach integrates financial analysis throughout development.

Continuous Cost-Benefit Analysis

Design teams perform ongoing cost-benefit analyses for every design choice. They evaluate the impact of material selection, geometric complexity, and manufacturing processes on the final price. This continuous assessment guides decisions toward the most cost-effective solutions without compromising performance.

Phased Design Improvements

Designers implement improvements in phases, allowing for incremental adjustments and cost evaluations at each step. This methodical approach ensures that each design iteration moves closer to an optimized, cost-efficient solution. It also provides opportunities to incorporate feedback and refine the design based on real-world manufacturing constraints.

Optimize Part Features

Optimizing individual part features directly influences material consumption and manufacturing complexity. Thoughtful design choices can significantly reduce overall expenses.

Reducing Cavity Depth

Deep cavities often require extensive machining and can lead to increased tool wear and longer cycle times. Designers can modify part geometry to reduce cavity depth where functionally permissible. This simplification saves material and reduces machining effort.

Avoiding Excessive NRE Costs

Non-Recurring Engineering (NRE) costs, such as tooling and setup, can be substantial. Designers aim to create parts that minimize the need for specialized tooling or complex setups. This approach helps avoid excessive upfront expenses. Several optimized part features contribute to significant cost reductions:

- Lattice Structures: These designs reduce material volume and weight, lowering costs and accelerating print times while maintaining performance.

- Hollowing and Shelling Techniques: Creating hollow parts with thin outer walls minimizes the amount of titanium powder needed.

- Part Consolidation: Integrating multiple components into a single part eliminates assembly steps and reduces fastener requirements.

- Designing for As-Printed Surface Finishes: Specifying acceptable surface roughness for 3D-printed parts reduces the need for extensive post-machining.

- Integrating Features Directly into the Print: Incorporating threads, fasteners, or internal channels directly into the 3D model eliminates subsequent manufacturing steps.

- Optimizing Part Orientation: Strategic placement on the build plate minimizes support requirements and reduces build time.

- Nesting and Batching: Arranging multiple parts on a single build plate optimizes build volume utilization and maximizes throughput, leading to substantial material savings.

Manufacturers can significantly reduce cost in custom titanium parts by optimizing material selection, embracing advanced manufacturing, minimizing waste, reducing energy consumption, streamlining post-processing, and leveraging smart design. These strategic investments and process optimizations yield substantial long-term financial benefits. A holistic approach, integrating these strategies, is essential for sustainable savings. Proactive adoption of advanced techniques and collaborative partnerships drives continuous improvement and efficiency.

FAQ

How does material selection impact titanium part cost?

Choosing the right titanium grade balances performance and cost. Strategic procurement, like bulk purchasing and strong supplier relationships, also lowers material expenses. Utilizing near-net shape materials further reduces initial volume and machining needs.

Can 3D printing reduce titanium part expenses?

Yes, additive manufacturing (3D printing) minimizes material waste by building parts layer by layer. It efficiently produces complex geometries without expensive tooling. This method often proves more cost-effective for small to medium batches.

Why is minimizing material waste important for titanium?

Titanium is an expensive material. Minimizing waste directly impacts the bottom line. Techniques like Design for Manufacturability (DFM), efficient nesting, and proper chip recycling conserve material. This reduces overall production costs significantly.

How do advanced cooling methods save energy during machining?

Advanced cooling, such as through-spindle coolant or MQL, minimizes heat generation in the cutting zone. This reduces friction and energy consumption. It also extends tool life, leading to fewer tool changes and lower operating costs.

What role does Design for Manufacturability (DFM) play in cost reduction?

DFM simplifies part geometry and reduces unnecessary features. This approach minimizes material removal and machining time. It also lowers the amount of scrap generated, directly contributing to significant cost savings.

Is recycling titanium scrap cost-effective?

Yes, titanium scrap is a valuable commodity. Manufacturers can sell collected chips and offcuts to recyclers. This practice offsets initial material costs. Advanced recycling techniques also make recycled titanium a more affordable alternative to virgin material.

How does virtual prototyping save money in titanium part development?

Virtual prototyping and simulation tools allow engineers to test designs digitally. This reduces the need for expensive physical prototypes. It also identifies design flaws early, preventing costly rework and material waste in later production stages.