3D printed titanium frames typically do not require welding for their primary structural integrity. Manufacturers produce these frames as single, monolithic components. However, welding becomes essential in specific situations. These include joining multiple printed parts or repairing damage. Integrating non-printed elements also necessitates welding processes.

Key Takeaways

- 3D printed titanium frames usually do not need welding. They are made as one strong piece.

- Welding is needed to join many printed parts. It also fixes damage or adds other parts.

- Advanced methods like DMLS and SLM build strong titanium parts. They create dense, uniform structures.

- Single-piece 3D printed frames are very strong. They have no weak spots from welds.

- Welding 3D printed titanium is hard. It needs special care due to the material’s unique structure.

- Welding changes the material near the weld. Post-weld treatments help fix these changes.

- Designing frames without welds makes them stronger. It also makes them last longer and simplifies making them.

Understanding Monolithic 3D Printed Titanium Frames

How Additive Manufacturing Creates Strong Titanium Parts

Additive manufacturing revolutionizes how manufacturers create strong titanium parts. This technology builds components layer by layer. It uses precise fusion processes.

Layer-by-Layer Fusion Processes (DMLS, SLM, EBM)

Several advanced processes contribute to the strength of 3D printed titanium. Direct Metal Laser Sintering (DMLS) uses a laser to fuse metal powder particles. Selective Laser Melting (SLM) fully melts the powder, creating a dense part. Electron Beam Melting (EBM) employs an electron beam in a vacuum to melt and fuse powder. These methods precisely control material deposition and solidification.

The ADDere additive manufacturing system utilizes a laser-wire process. This system directly prints large-scale titanium components. This method allows for rapid iteration and fabrication of complex designs. It produces near-net-shaped parts. These parts require minimal finish machining. This approach leads to more efficient and stronger titanium components. It reduces material waste and machining time compared to conventional methods.

Sciaky employs Electron Beam Additive Manufacturing (EBAM) processes for titanium 3D printing. This technology is particularly effective for titanium alloys. It combines the material’s inherent advantages with the design flexibility of additive manufacturing. EBAM addresses challenges of working with titanium. These challenges include its reactivity and hardness. It provides a method for building high-precision titanium parts layer by layer.

Achieving Dense, Homogeneous Structures

These layer-by-layer fusion processes ensure the creation of dense structures. They minimize internal voids and defects. The controlled melting and solidification result in a fine, homogeneous microstructure. This microstructure contributes significantly to the material’s strength and durability. Manufacturers can achieve properties comparable to traditionally manufactured titanium.

The Inherent Strength of Single-Piece 3D Printed Titanium Frames

Single-piece 3D printed titanium frames possess inherent strength. Their manufacturing process eliminates weak points often found in assembled parts.

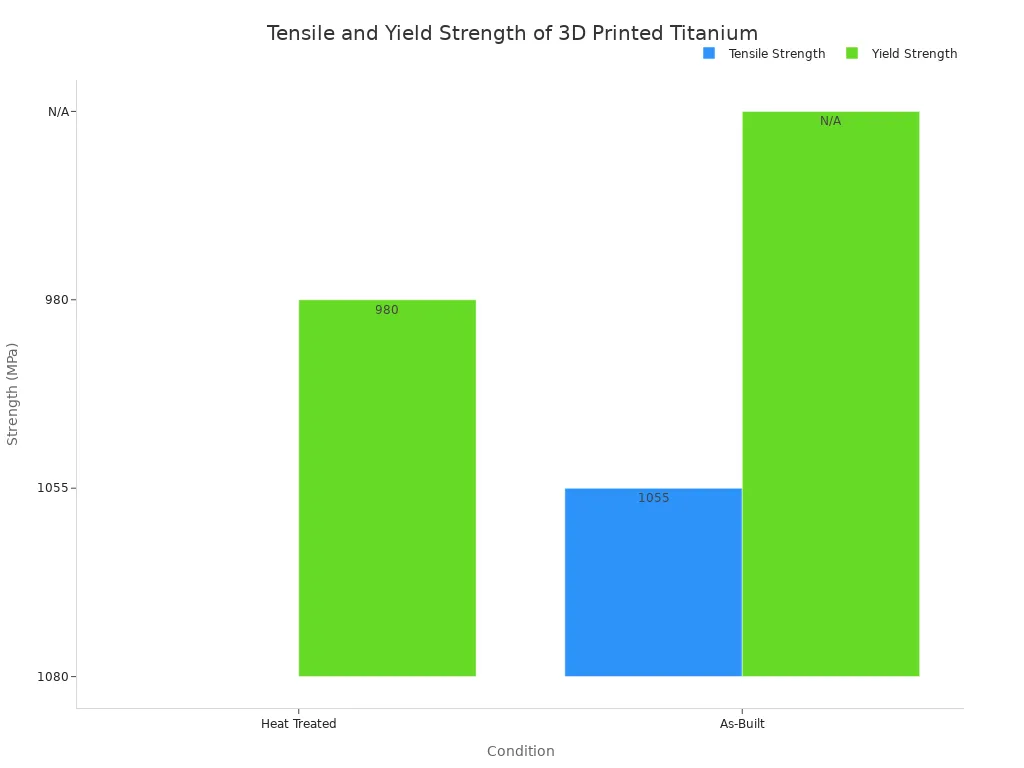

Mechanical Properties Comparable to Wrought Titanium

3D printed titanium exhibits impressive mechanical properties. These properties are often comparable to wrought titanium. Wrought titanium undergoes shaping through deformation. The additive manufacturing process creates materials with high tensile and yield strengths.

| Condition | Tensile Strength (MPa) | Yield Strength (MPa) |

|---|---|---|

| Heat Treated | 1080 | 980 |

| As-Built | 1055 | N/A |

3D printed titanium typically exhibits a tensile strength of around 1200 MPa. It has a yield strength of approximately 880 MPa. These values can vary. Specific processing methods and alloying elements influence them.

Absence of Traditional Weld Seams in Monolithic Designs

Monolithic designs eliminate traditional weld seams. Welds are often points of weakness in conventionally fabricated structures. The continuous, single-piece construction of 3D printed titanium frames enhances their overall integrity. This design reduces the risk of fatigue failure.

While 3D printed titanium alloys offer advantages like personalized customization, their fatigue strength can be weaker than traditional titanium implants. This fatigue strength links closely to porosity and surface morphology. However, surface modification technologies improve fatigue strength. Examples include shot peening or TiO2 nanotube coating. These methods enhance the service life of 3D-printed titanium alloys.

3D printed titanium components can exhibit excellent fatigue properties. Modern 3D printing techniques address previous concerns. They achieve this through microstructural optimization. It is possible to create ‘Net-AM’ microstructures. These microstructures demonstrate exceptionally high fatigue resistance. They surpass most additively manufactured and even forged titanium alloys. Post-processing methods also improve density. These methods include heat treatment and Hot Isostatic Pressing (HIP). They eliminate residual stress and enhance fatigue strength. This leads to final parts comparable to or better than traditionally forged or machined components.

When Welding Becomes Essential for 3D Printed Titanium Frames

While 3D printed titanium frames often achieve structural integrity as single, monolithic units, specific situations necessitate welding. These scenarios typically involve combining multiple components, repairing damage, or integrating non-printed elements into the frame structure.

Joining Multiple 3D Printed Components

Manufacturers often need to join multiple 3D printed components for various reasons. This approach allows for the creation of larger structures or parts with optimized properties.

Assembling Large or Modular Frame Sections

Additive manufacturing build volumes have limitations. Therefore, designers often segment large 3D printed titanium frames into smaller, manageable sections. They then assemble these sections post-printing. This modular approach allows for the production of structures exceeding the physical dimensions of a single 3D printer. For example, if a part experiences misalignment during the printing process, a visible flaw might appear where sections were intended to join. These components then require post-printing joining to achieve an acceptable production standard.

When joining large 3D printed titanium frame sections, specific welding techniques prove effective. For slip-fit parts, technicians treat them as normal mitered joints, fuse them, and then cap the weld. Butt joints require a single pass with filler material. Welders ensure settings, especially if pulsed, allow for the fusion of the entire part plug, which often demands more filler than usual. They utilize a small filler lip on titanium parts, frequently supplementing it with additional filler (e.g., .028″) for both structural integrity and aesthetics. Optimizing welding settings for each part based on its structural and aesthetic requirements is crucial. Some processes consider using fusion rings, such as a 1mm thick lip extending 1.3mm, to aid welding, even if print defects like ‘broken edges’ melt during the process. Post-weld heat treatment addresses any residual stress.

Connecting Complex Geometries Beyond Single Print Capabilities

Designers also segment complex geometries into multiple parts when a single print cannot achieve the desired intricacy or functionality. This strategy allows for the selective placement of materials to achieve specific properties. For instance, when designing components like a wrench for space station use, both strength and weight are critical. Different materials, potentially including titanium, might be printed separately and then joined. This enables a lighter handle while maintaining a strong working end. Similarly, biomedical implants require tailored functionality. For titanium implants, integrating other materials like zinc and magnesium for bone growth is necessary, while retaining titanium’s inherent strength. This involves printing different sections or materials separately and then joining them to create an implant with optimized mechanical stability and biological interaction.

Repairing Damaged 3D Printed Titanium Frames

Even robust 3D printed titanium frames can sustain damage during their operational lifespan. Welding offers a viable solution for repairing these components.

Addressing Cracks, Breaks, or Structural Failures

Welding becomes essential for addressing various forms of damage, including cracks, breaks, or other structural failures. A skilled technician can restore the frame’s integrity by carefully preparing the damaged area and applying appropriate welding techniques. This process extends the service life of the component and avoids costly replacements.

Similarities and Differences to Traditional Titanium Repair

Repairing 3D printed titanium frames shares similarities with traditional titanium welding. Both processes require an inert atmosphere to prevent contamination and oxidation, given titanium’s high reactivity. However, differences exist. The microstructure of 3D printed titanium can vary from wrought titanium, potentially influencing weldability and requiring adjustments in welding parameters. The presence of residual stresses from the additive manufacturing process also demands careful consideration during repair welding to prevent further distortion or cracking.

Integrating Non-Printed Elements into 3D Printed Titanium Frames

Hybrid manufacturing approaches often combine the benefits of 3D printing with traditional manufacturing methods. This integration frequently requires welding.

Attaching Mounting Brackets and Specialized Connectors

Many applications require the attachment of non-printed elements to 3D printed titanium frames. These elements might include mounting brackets for sensors, specialized connectors for electrical systems, or interfaces for other mechanical components. Welding provides a strong, permanent bond for these attachments, ensuring the overall functionality and reliability of the assembly.

Hybrid Manufacturing Approaches Combining Printed and Traditional Parts

Hybrid manufacturing leverages the design freedom of additive manufacturing for complex geometries and the cost-effectiveness or specific material properties of traditional parts. For example, a complex internal structure might be 3D printed, while external, simpler components are machined or cast. Welding then joins these disparate parts into a cohesive unit. This approach optimizes both performance and manufacturing efficiency.

Specific Challenges of Welding 3D Printed Titanium Frames

Welding 3D printed titanium frames presents unique challenges. These challenges stem from the material’s distinct metallurgical characteristics and the stringent technical requirements for successful joining. Welders must understand these factors to ensure the integrity and performance of the final product.

Metallurgical Differences and Weldability

The additive manufacturing process imparts specific microstructural features to titanium. These features significantly influence how the material behaves during welding.

Impact of 3D Printed Microstructure on Welding

3D printed Ti-6Al-4V samples exhibit larger primary β grains compared to wrought (rolled) samples. This structural difference leads to higher thermal conductivity in the printed material. Increased thermal conductivity results in wider welds and a faster cooling rate during the welding process. The rapid cooling limits crystallite growth in the weld metal. It also reduces the heat-affected zone (HAZ) size. The HAZ in 3D printed samples is approximately half as wide as in rolled samples. Furthermore, the higher cooling rate in 3D printed samples leads to a lower volume fraction of residual β phase in the weld metal. These microstructural variations demand careful adjustment of welding parameters.

Unique Properties of 3D Printed Titanium

3D printed titanium often possesses anisotropic properties. This means its mechanical characteristics can vary depending on the build direction. Residual stresses can also exist within the material from the layer-by-layer printing process. These unique properties can affect weld penetration, fusion, and the formation of defects. Welders must account for these inherent material characteristics to achieve sound joints.

Best Practices and Technical Requirements for Welding

Successful welding of 3D printed titanium requires adherence to strict best practices and technical specifications.

Inert Atmosphere and Contamination Control

Titanium reacts readily with atmospheric gases like oxygen and nitrogen at elevated temperatures. This reactivity can lead to embrittlement and porosity in the weld. Therefore, maintaining an inert atmosphere is paramount. Welders typically use high-purity argon gas shielding for both the weld pool and the surrounding hot metal. They also employ specialized chambers or trailing shields to prevent contamination.

Filler Material Selection and Compatibility

Selecting the correct filler material is crucial for achieving strong and ductile welds. The filler metal must be compatible with the base 3D printed titanium alloy. It should match the mechanical properties and corrosion resistance of the parent material.

| ASTM Base Metal Grade | Base metal | Recommended Filler Metal |

|---|---|---|

| Grade 1 | Unalloyed Ti CP1 | ERTi-1 |

| Grade 2 | Unalloyed Ti CP2 | ERTi-2 |

| Grade 4 | Unalloyed Ti CP4 | ERTi-4 |

| Grade 5 | Ti 6AL-4V | ERTi-5 |

| Grade 7 | Ti 0.15Pd | ERTi-7 |

Titanium Welding Wire ErTi1 Titanium Alloy Wire Grade 1 Grade 5 is marketed as suitable for ‘3D Printing Metal’. This indicates specific filler materials are developed for additive manufacturing applications.

Expertise Required for Successful Welds

Welding titanium, especially 3D printed variants, demands significant expertise. Welders must possess a deep understanding of titanium metallurgy, welding processes, and contamination control. They need specialized training and experience to consistently produce high-quality welds. Improper technique can lead to defects, compromising the structural integrity of the component.

Impact of Welding on 3D Printed Titanium Frame Properties

Welding introduces significant changes to the material properties of 3D printed titanium frames. These alterations primarily occur within the heat-affected zone (HAZ) and can influence the overall performance and longevity of the component.

Heat-Affected Zones (HAZ) and Material Alterations

The heat from welding creates a localized area known as the heat-affected zone. This zone experiences microstructural changes without melting.

Changes in Local Mechanical Properties

The HAZ in welded 3D printed titanium differs from that in wrought titanium.

- 3D Printed Titanium HAZ:

- Composed of fine equiaxed grains.

- Microhardness is lower than that of wrought welds. This is due to finer microstructure grains.

- In some cases, the HAZ microstructure closely resembles the fusion zone. This makes differentiation difficult.

- Wrought Titanium HAZ:

- Primarily consists of blocky α and some untransformed β and α phases near the base metal.

- Near the fusion zone, it exhibits an α martensitic microstructure. This leads to higher hardness in that region compared to the base metal.

- Microhardness is generally higher than in additively manufactured welds.

- It shows a clear transition. Acicular martensite decreases away from the weld center. Grain boundary α phase forms.

In friction stir welded electron beam printed Ti-6Al-4V plates, the thermo-mechanically affected zone (TMAZ) showed the highest hardness. This observation deviates from the typical trend. The stir zone (SZ) usually shows the highest hardness. The reduction in hardness/strength in the SZ was attributed to the presence of tungsten-cobalt-rich particles and coarser β grains. These formed a soft zone.

Potential for Residual Stresses and Distortion

Welding introduces thermal gradients. These gradients can lead to residual stresses within the material. These stresses can cause distortion in the frame. They can also reduce the fatigue life of the component. Careful control of welding parameters helps minimize these adverse effects.

Post-Weld Treatments and Quality Assurance

Post-weld treatments are crucial for restoring optimal properties and ensuring the integrity of welded 3D printed titanium frames.

Stress Relief and Heat Treatment Considerations

Post-weld heat treatments at 650 °C and 750 °C effectively mitigate residual stresses in titanium welds. Specifically, a 750 °C heat treatment leads to more complete stress relaxation compared to a 650 °C treatment. In as-welded conditions, peak tensile residual stress in the weld center zone (WCZ) was 709.2 MPa. After 650 °C treatment, this was reduced to 114.4 MPa. Following 750 °C treatment, residual stress throughout the entire weld, including the WCZ, was significantly reduced. This indicates the superior effectiveness of the higher temperature.

Post-weld heat treatment (PWHT) is a recognized mitigation strategy for reducing residual stresses in titanium welds. Some studies show reductions of over 90%. Beyond stress relief, PWHT also contributes to microstructural homogenization. It enhances mechanical properties. This approach addresses high residual stresses. These stresses can significantly impact fatigue crack propagation. They can compromise fatigue life predictions.

Non-Destructive Testing (NDT) for Weld Integrity

Non-destructive testing (NDT) methods are essential for evaluating weld quality without damaging the component.

- X-ray scanning is used for post-build non-destructive testing. It detects internal flaws like porosity in 3D printed titanium frames.

- CT scanning is used for post-build non-destructive testing. It detects internal flaws like porosity in 3D printed titanium frames.

After welding, additional NDT methods ensure weld integrity.

- X-ray methods are used for post-weld non-destructive testing.

- Ultrasonic methods are used for post-weld non-destructive testing.

Design Considerations for Weld-Free 3D Printed Titanium Frames

Designers prioritize specific principles when creating 3D printed titanium frames without welds. These considerations leverage the unique capabilities of additive manufacturing. They aim to produce strong, efficient, and durable components.

Optimizing Designs for Monolithic Production

Optimizing designs for monolithic production focuses on creating single, integrated parts. This approach eliminates the need for joining separate components.

Maximizing Structural Integrity Through Integrated Design

Integrated design significantly enhances structural integrity. Additive manufacturing allows for the creation of complex, rider-specific geometries. This approach reduces welding, thereby minimizing assembly failure points. It also improves overall strength and structural stability. Computational tools like topology optimization are crucial. They optimize structural elements, placing material only where necessary. This creates strong yet lightweight components. Metal additive manufacturing facilitates complex internal geometries. Traditional methods like stamping or casting cannot achieve these. This further contributes to optimized structures.

Leveraging Design Freedom for Complex Geometries

Additive manufacturing offers unparalleled design freedom. Designers can combine multiple assembly components into a single, monolithic printed part. This reduces part count and eliminates joints or fasteners. It also improves structural efficiency and integrates functionality. Topology optimization helps create organic, efficient structures with significant weight savings. Designers incorporate complex internal features like lattices for weight reduction and tailored stiffness. They also include conformal channels for fluids or wiring. This requires careful consideration for powder removal. Designs focus on functional requirements, such as load paths and stiffness, rather than traditional manufacturing constraints. The complexity of features, internal channels, and complex curvatures has minimal impact on AM production costs. Designers also aim for self-supporting angles, typically greater than 45° from horizontal. This reduces material cost, print time, and post-processing. They adhere to AM process limits for minimum wall thickness (e.g., 0.4-1.0 mm) and hole/pin diameters (e.g., >0.5-1.0 mm). This ensures reliable production and avoids distortion or sealing issues.

Advantages of Eliminating Welds in 3D Printed Titanium Frames

Eliminating welds offers significant benefits for the performance and manufacturing of 3D printed titanium frames.

Enhanced Fatigue Resistance and Durability

The absence of welds directly contributes to enhanced fatigue resistance and durability. Issues in traditional titanium frames typically occur at the welds, for example, at the bottom bracket and rear dropouts. Problems can also arise where tubing has been cold-worked, such as bent, crimped, or shaped. These areas are susceptible to human error. Cracking in welds can develop over time. However, it is usually noticeable before catastrophic failure. Advanced manufacturing technologies, including 3D printing, eliminate the risks associated with welding. This results in a more reliable and structurally sound product. It directly contributes to the overall durability and lifespan of 3D printed titanium frames by removing a common point of failure.

Reduced Manufacturing Steps and Inspection Needs

Monolithic production significantly reduces manufacturing steps. It eliminates the need for separate welding processes and subsequent inspections. This streamlines the production workflow. It also lowers labor costs and accelerates time to market. The inherent integrity of a single-piece component minimizes the need for extensive post-production quality checks related to weld integrity.

3D printed titanium frames do not inherently require welding. Manufacturers produce them as single, integrated components, leveraging additive manufacturing’s strength. Welding becomes necessary for specific applications. These include joining multiple printed sections, repairing damage, or integrating non-printed elements. Welding 3D printed titanium frames presents unique challenges. Understanding these considerations is crucial for successful hybrid designs and repairs.

FAQ

Do all 3D printed titanium frames require welding?

No, 3D printed titanium frames do not inherently require welding. Manufacturers often produce them as single, monolithic components. This process leverages additive manufacturing’s strength, eliminating the need for traditional welds in the primary structure.

When does welding become necessary for 3D printed titanium frames?

Welding becomes essential in specific situations. These include joining multiple printed sections to create larger structures. It is also necessary for repairing damaged frames or integrating non-printed elements like mounting brackets into the design.

What makes welding 3D printed titanium challenging?

Welding 3D printed titanium presents challenges due to its unique microstructure and potential residual stresses. Titanium’s high reactivity with atmospheric gases also demands an inert atmosphere. Welders require specialized expertise and precise control to achieve sound joints.

How does welding impact the properties of a 3D printed titanium frame?

Welding creates a heat-affected zone (HAZ) where the material’s microstructure changes. This can alter local mechanical properties. Welding also introduces residual stresses and potential distortion. Post-weld treatments help mitigate these effects.

Can manufacturers repair damaged 3D printed titanium frames using welding?

Yes, welding offers a viable solution for repairing damaged 3D printed titanium frames. Technicians can address cracks, breaks, or structural failures. This process extends the component’s service life, but requires careful technique due to the material’s specific characteristics.

What are the advantages of designing weld-free 3D printed titanium frames?

Eliminating welds enhances fatigue resistance and durability. It removes common failure points found in traditional welded structures. This approach also reduces manufacturing steps and inspection needs, streamlining production and improving overall product reliability.

What post-weld treatments are important for 3D printed titanium?

Post-weld heat treatments, such as stress relief at specific temperatures, are crucial. These treatments reduce residual stresses and improve microstructural homogeneity. Non-destructive testing (NDT) methods like X-ray or ultrasonic inspections then ensure weld integrity.

3D printed titanium frames typically do not require welding for their primary structural integrity. Manufacturers produce these frames as single, monolithic components. However, welding becomes essential in specific situations. These include joining multiple printed parts or repairing damage. Integrating non-printed elements also necessitates welding processes.

Key Takeaways

- 3D printed titanium frames usually do not need welding. They are made as one strong piece.

- Welding is needed to join many printed parts. It also fixes damage or adds other parts.

- Advanced methods like DMLS and SLM build strong titanium parts. They create dense, uniform structures.

- Single-piece 3D printed frames are very strong. They have no weak spots from welds.

- Welding 3D printed titanium is hard. It needs special care due to the material’s unique structure.

- Welding changes the material near the weld. Post-weld treatments help fix these changes.

- Designing frames without welds makes them stronger. It also makes them last longer and simplifies making them.

Understanding Monolithic 3D Printed Titanium Frames

How Additive Manufacturing Creates Strong Titanium Parts

Additive manufacturing revolutionizes how manufacturers create strong titanium parts. This technology builds components layer by layer. It uses precise fusion processes.

Layer-by-Layer Fusion Processes (DMLS, SLM, EBM)

Several advanced processes contribute to the strength of 3D printed titanium. Direct Metal Laser Sintering (DMLS) uses a laser to fuse metal powder particles. Selective Laser Melting (SLM) fully melts the powder, creating a dense part. Electron Beam Melting (EBM) employs an electron beam in a vacuum to melt and fuse powder. These methods precisely control material deposition and solidification.

The ADDere additive manufacturing system utilizes a laser-wire process. This system directly prints large-scale titanium components. This method allows for rapid iteration and fabrication of complex designs. It produces near-net-shaped parts. These parts require minimal finish machining. This approach leads to more efficient and stronger titanium components. It reduces material waste and machining time compared to conventional methods.

Sciaky employs Electron Beam Additive Manufacturing (EBAM) processes for titanium 3D printing. This technology is particularly effective for titanium alloys. It combines the material’s inherent advantages with the design flexibility of additive manufacturing. EBAM addresses challenges of working with titanium. These challenges include its reactivity and hardness. It provides a method for building high-precision titanium parts layer by layer.

Achieving Dense, Homogeneous Structures

These layer-by-layer fusion processes ensure the creation of dense structures. They minimize internal voids and defects. The controlled melting and solidification result in a fine, homogeneous microstructure. This microstructure contributes significantly to the material’s strength and durability. Manufacturers can achieve properties comparable to traditionally manufactured titanium.

The Inherent Strength of Single-Piece 3D Printed Titanium Frames

Single-piece 3D printed titanium frames possess inherent strength. Their manufacturing process eliminates weak points often found in assembled parts.

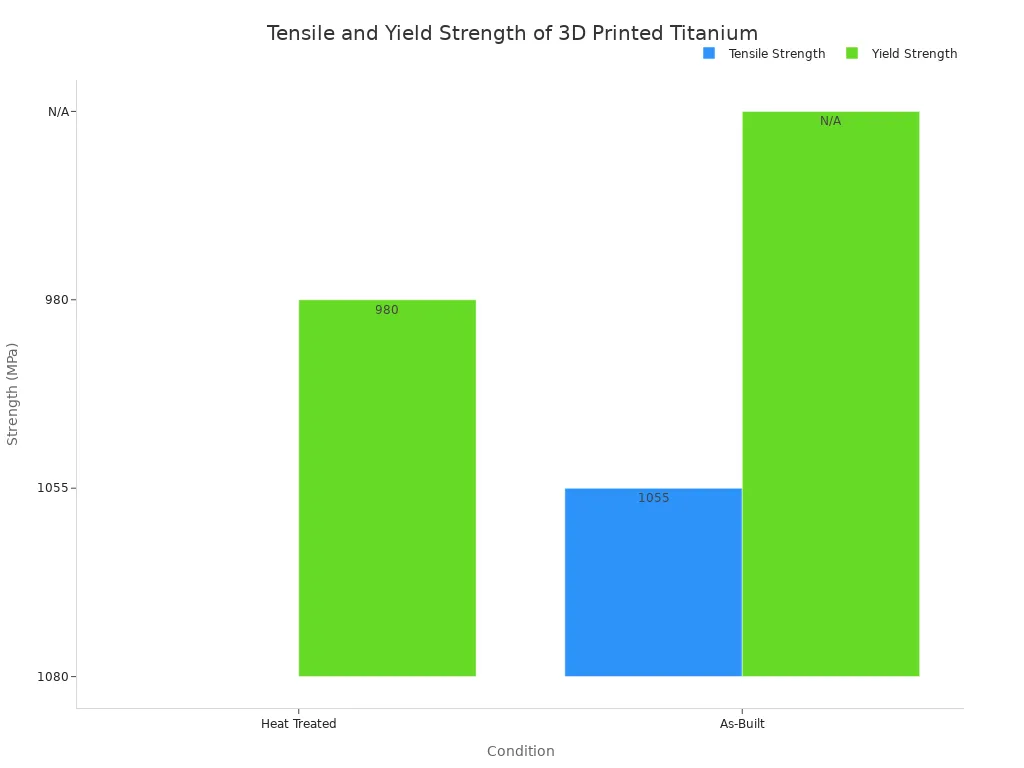

Mechanical Properties Comparable to Wrought Titanium

3D printed titanium exhibits impressive mechanical properties. These properties are often comparable to wrought titanium. Wrought titanium undergoes shaping through deformation. The additive manufacturing process creates materials with high tensile and yield strengths.

| Condition | Tensile Strength (MPa) | Yield Strength (MPa) |

|---|---|---|

| Heat Treated | 1080 | 980 |

| As-Built | 1055 | N/A |

3D printed titanium typically exhibits a tensile strength of around 1200 MPa. It has a yield strength of approximately 880 MPa. These values can vary. Specific processing methods and alloying elements influence them.

Absence of Traditional Weld Seams in Monolithic Designs

Monolithic designs eliminate traditional weld seams. Welds are often points of weakness in conventionally fabricated structures. The continuous, single-piece construction of 3D printed titanium frames enhances their overall integrity. This design reduces the risk of fatigue failure.

While 3D printed titanium alloys offer advantages like personalized customization, their fatigue strength can be weaker than traditional titanium implants. This fatigue strength links closely to porosity and surface morphology. However, surface modification technologies improve fatigue strength. Examples include shot peening or TiO2 nanotube coating. These methods enhance the service life of 3D-printed titanium alloys.

3D printed titanium components can exhibit excellent fatigue properties. Modern 3D printing techniques address previous concerns. They achieve this through microstructural optimization. It is possible to create ‘Net-AM’ microstructures. These microstructures demonstrate exceptionally high fatigue resistance. They surpass most additively manufactured and even forged titanium alloys. Post-processing methods also improve density. These methods include heat treatment and Hot Isostatic Pressing (HIP). They eliminate residual stress and enhance fatigue strength. This leads to final parts comparable to or better than traditionally forged or machined components.

When Welding Becomes Essential for 3D Printed Titanium Frames

While 3D printed titanium frames often achieve structural integrity as single, monolithic units, specific situations necessitate welding. These scenarios typically involve combining multiple components, repairing damage, or integrating non-printed elements into the frame structure.

Joining Multiple 3D Printed Components

Manufacturers often need to join multiple 3D printed components for various reasons. This approach allows for the creation of larger structures or parts with optimized properties.

Assembling Large or Modular Frame Sections

Additive manufacturing build volumes have limitations. Therefore, designers often segment large 3D printed titanium frames into smaller, manageable sections. They then assemble these sections post-printing. This modular approach allows for the production of structures exceeding the physical dimensions of a single 3D printer. For example, if a part experiences misalignment during the printing process, a visible flaw might appear where sections were intended to join. These components then require post-printing joining to achieve an acceptable production standard.

When joining large 3D printed titanium frame sections, specific welding techniques prove effective. For slip-fit parts, technicians treat them as normal mitered joints, fuse them, and then cap the weld. Butt joints require a single pass with filler material. Welders ensure settings, especially if pulsed, allow for the fusion of the entire part plug, which often demands more filler than usual. They utilize a small filler lip on titanium parts, frequently supplementing it with additional filler (e.g., .028″) for both structural integrity and aesthetics. Optimizing welding settings for each part based on its structural and aesthetic requirements is crucial. Some processes consider using fusion rings, such as a 1mm thick lip extending 1.3mm, to aid welding, even if print defects like ‘broken edges’ melt during the process. Post-weld heat treatment addresses any residual stress.

Connecting Complex Geometries Beyond Single Print Capabilities

Designers also segment complex geometries into multiple parts when a single print cannot achieve the desired intricacy or functionality. This strategy allows for the selective placement of materials to achieve specific properties. For instance, when designing components like a wrench for space station use, both strength and weight are critical. Different materials, potentially including titanium, might be printed separately and then joined. This enables a lighter handle while maintaining a strong working end. Similarly, biomedical implants require tailored functionality. For titanium implants, integrating other materials like zinc and magnesium for bone growth is necessary, while retaining titanium’s inherent strength. This involves printing different sections or materials separately and then joining them to create an implant with optimized mechanical stability and biological interaction.

Repairing Damaged 3D Printed Titanium Frames

Even robust 3D printed titanium frames can sustain damage during their operational lifespan. Welding offers a viable solution for repairing these components.

Addressing Cracks, Breaks, or Structural Failures

Welding becomes essential for addressing various forms of damage, including cracks, breaks, or other structural failures. A skilled technician can restore the frame’s integrity by carefully preparing the damaged area and applying appropriate welding techniques. This process extends the service life of the component and avoids costly replacements.

Similarities and Differences to Traditional Titanium Repair

Repairing 3D printed titanium frames shares similarities with traditional titanium welding. Both processes require an inert atmosphere to prevent contamination and oxidation, given titanium’s high reactivity. However, differences exist. The microstructure of 3D printed titanium can vary from wrought titanium, potentially influencing weldability and requiring adjustments in welding parameters. The presence of residual stresses from the additive manufacturing process also demands careful consideration during repair welding to prevent further distortion or cracking.

Integrating Non-Printed Elements into 3D Printed Titanium Frames

Hybrid manufacturing approaches often combine the benefits of 3D printing with traditional manufacturing methods. This integration frequently requires welding.

Attaching Mounting Brackets and Specialized Connectors

Many applications require the attachment of non-printed elements to 3D printed titanium frames. These elements might include mounting brackets for sensors, specialized connectors for electrical systems, or interfaces for other mechanical components. Welding provides a strong, permanent bond for these attachments, ensuring the overall functionality and reliability of the assembly.

Hybrid Manufacturing Approaches Combining Printed and Traditional Parts

Hybrid manufacturing leverages the design freedom of additive manufacturing for complex geometries and the cost-effectiveness or specific material properties of traditional parts. For example, a complex internal structure might be 3D printed, while external, simpler components are machined or cast. Welding then joins these disparate parts into a cohesive unit. This approach optimizes both performance and manufacturing efficiency.

Specific Challenges of Welding 3D Printed Titanium Frames

Welding 3D printed titanium frames presents unique challenges. These challenges stem from the material’s distinct metallurgical characteristics and the stringent technical requirements for successful joining. Welders must understand these factors to ensure the integrity and performance of the final product.

Metallurgical Differences and Weldability

The additive manufacturing process imparts specific microstructural features to titanium. These features significantly influence how the material behaves during welding.

Impact of 3D Printed Microstructure on Welding

3D printed Ti-6Al-4V samples exhibit larger primary β grains compared to wrought (rolled) samples. This structural difference leads to higher thermal conductivity in the printed material. Increased thermal conductivity results in wider welds and a faster cooling rate during the welding process. The rapid cooling limits crystallite growth in the weld metal. It also reduces the heat-affected zone (HAZ) size. The HAZ in 3D printed samples is approximately half as wide as in rolled samples. Furthermore, the higher cooling rate in 3D printed samples leads to a lower volume fraction of residual β phase in the weld metal. These microstructural variations demand careful adjustment of welding parameters.

Unique Properties of 3D Printed Titanium

3D printed titanium often possesses anisotropic properties. This means its mechanical characteristics can vary depending on the build direction. Residual stresses can also exist within the material from the layer-by-layer printing process. These unique properties can affect weld penetration, fusion, and the formation of defects. Welders must account for these inherent material characteristics to achieve sound joints.

Best Practices and Technical Requirements for Welding

Successful welding of 3D printed titanium requires adherence to strict best practices and technical specifications.

Inert Atmosphere and Contamination Control

Titanium reacts readily with atmospheric gases like oxygen and nitrogen at elevated temperatures. This reactivity can lead to embrittlement and porosity in the weld. Therefore, maintaining an inert atmosphere is paramount. Welders typically use high-purity argon gas shielding for both the weld pool and the surrounding hot metal. They also employ specialized chambers or trailing shields to prevent contamination.

Filler Material Selection and Compatibility

Selecting the correct filler material is crucial for achieving strong and ductile welds. The filler metal must be compatible with the base 3D printed titanium alloy. It should match the mechanical properties and corrosion resistance of the parent material.

| ASTM Base Metal Grade | Base metal | Recommended Filler Metal |

|---|---|---|

| Grade 1 | Unalloyed Ti CP1 | ERTi-1 |

| Grade 2 | Unalloyed Ti CP2 | ERTi-2 |

| Grade 4 | Unalloyed Ti CP4 | ERTi-4 |

| Grade 5 | Ti 6AL-4V | ERTi-5 |

| Grade 7 | Ti 0.15Pd | ERTi-7 |

Titanium Welding Wire ErTi1 Titanium Alloy Wire Grade 1 Grade 5 is marketed as suitable for ‘3D Printing Metal’. This indicates specific filler materials are developed for additive manufacturing applications.

Expertise Required for Successful Welds

Welding titanium, especially 3D printed variants, demands significant expertise. Welders must possess a deep understanding of titanium metallurgy, welding processes, and contamination control. They need specialized training and experience to consistently produce high-quality welds. Improper technique can lead to defects, compromising the structural integrity of the component.

Impact of Welding on 3D Printed Titanium Frame Properties

Welding introduces significant changes to the material properties of 3D printed titanium frames. These alterations primarily occur within the heat-affected zone (HAZ) and can influence the overall performance and longevity of the component.

Heat-Affected Zones (HAZ) and Material Alterations

The heat from welding creates a localized area known as the heat-affected zone. This zone experiences microstructural changes without melting.

Changes in Local Mechanical Properties

The HAZ in welded 3D printed titanium differs from that in wrought titanium.

- 3D Printed Titanium HAZ:

- Composed of fine equiaxed grains.

- Microhardness is lower than that of wrought welds. This is due to finer microstructure grains.

- In some cases, the HAZ microstructure closely resembles the fusion zone. This makes differentiation difficult.

- Wrought Titanium HAZ:

- Primarily consists of blocky α and some untransformed β and α phases near the base metal.

- Near the fusion zone, it exhibits an α martensitic microstructure. This leads to higher hardness in that region compared to the base metal.

- Microhardness is generally higher than in additively manufactured welds.

- It shows a clear transition. Acicular martensite decreases away from the weld center. Grain boundary α phase forms.

In friction stir welded electron beam printed Ti-6Al-4V plates, the thermo-mechanically affected zone (TMAZ) showed the highest hardness. This observation deviates from the typical trend. The stir zone (SZ) usually shows the highest hardness. The reduction in hardness/strength in the SZ was attributed to the presence of tungsten-cobalt rich particles and coarser β grains. These formed a soft zone.

Potential for Residual Stresses and Distortion

Welding introduces thermal gradients. These gradients can lead to residual stresses within the material. These stresses can cause distortion in the frame. They can also reduce the fatigue life of the component. Careful control of welding parameters helps minimize these adverse effects.

Post-Weld Treatments and Quality Assurance

Post-weld treatments are crucial for restoring optimal properties and ensuring the integrity of welded 3D printed titanium frames.

Stress Relief and Heat Treatment Considerations

Post-weld heat treatments at 650 °C and 750 °C effectively mitigate residual stresses in titanium welds. Specifically, a 750 °C heat treatment leads to more complete stress relaxation compared to a 650 °C treatment. In as-welded conditions, peak tensile residual stress in the weld center zone (WCZ) was 709.2 MPa. After 650 °C treatment, this was reduced to 114.4 MPa. Following 750 °C treatment, residual stress throughout the entire weld, including the WCZ, was significantly reduced. This indicates the superior effectiveness of the higher temperature.

Post-weld heat treatment (PWHT) is a recognized mitigation strategy for reducing residual stresses in titanium welds. Some studies show reductions of over 90%. Beyond stress relief, PWHT also contributes to microstructural homogenization. It enhances mechanical properties. This approach addresses high residual stresses. These stresses can significantly impact fatigue crack propagation. They can compromise fatigue life predictions.

Non-Destructive Testing (NDT) for Weld Integrity

Non-destructive testing (NDT) methods are essential for evaluating weld quality without damaging the component.

- X-ray scanning is used for post-build non-destructive testing. It detects internal flaws like porosity in 3D printed titanium frames.

- CT scanning is used for post-build non-destructive testing. It detects internal flaws like porosity in 3D printed titanium frames.

After welding, additional NDT methods ensure weld integrity.

- X-ray methods are used for post-weld non-destructive testing.

- Ultrasonic methods are used for post-weld non-destructive testing.

Design Considerations for Weld-Free 3D Printed Titanium Frames

Designers prioritize specific principles when creating 3D printed titanium frames without welds. These considerations leverage the unique capabilities of additive manufacturing. They aim to produce strong, efficient, and durable components.

Optimizing Designs for Monolithic Production

Optimizing designs for monolithic production focuses on creating single, integrated parts. This approach eliminates the need for joining separate components.

Maximizing Structural Integrity Through Integrated Design

Integrated design significantly enhances structural integrity. Additive manufacturing allows for the creation of complex, rider-specific geometries. This approach reduces welding, thereby minimizing assembly failure points. It also improves overall strength and structural stability. Computational tools like topology optimization are crucial. They optimize structural elements, placing material only where necessary. This creates strong yet lightweight components. Metal additive manufacturing facilitates complex internal geometries. Traditional methods like stamping or casting cannot achieve these. This further contributes to optimized structures.

Leveraging Design Freedom for Complex Geometries

Additive manufacturing offers unparalleled design freedom. Designers can combine multiple assembly components into a single, monolithic printed part. This reduces part count and eliminates joints or fasteners. It also improves structural efficiency and integrates functionality. Topology optimization helps create organic, efficient structures with significant weight savings. Designers incorporate complex internal features like lattices for weight reduction and tailored stiffness. They also include conformal channels for fluids or wiring. This requires careful consideration for powder removal. Designs focus on functional requirements, such as load paths and stiffness, rather than traditional manufacturing constraints. The complexity of features, internal channels, and complex curvatures has minimal impact on AM production costs. Designers also aim for self-supporting angles, typically greater than 45° from horizontal. This reduces material cost, print time, and post-processing. They adhere to AM process limits for minimum wall thickness (e.g., 0.4-1.0 mm) and hole/pin diameters (e.g., >0.5-1.0 mm). This ensures reliable production and avoids distortion or sealing issues.

Advantages of Eliminating Welds in 3D Printed Titanium Frames

Eliminating welds offers significant benefits for the performance and manufacturing of 3D printed titanium frames.

Enhanced Fatigue Resistance and Durability

The absence of welds directly contributes to enhanced fatigue resistance and durability. Issues in traditional titanium frames typically occur at the welds, for example, at the bottom bracket and rear dropouts. Problems can also arise where tubing has been cold-worked, such as bent, crimped, or shaped. These areas are susceptible to human error. Cracking in welds can develop over time. However, it is usually noticeable before catastrophic failure. Advanced manufacturing technologies, including 3D printing, eliminate the risks associated with welding. This results in a more reliable and structurally sound product. It directly contributes to the overall durability and lifespan of 3D printed titanium frames by removing a common point of failure.

Reduced Manufacturing Steps and Inspection Needs

Monolithic production significantly reduces manufacturing steps. It eliminates the need for separate welding processes and subsequent inspections. This streamlines the production workflow. It also lowers labor costs and accelerates time to market. The inherent integrity of a single-piece component minimizes the need for extensive post-production quality checks related to weld integrity.

3D printed titanium frames do not inherently require welding. Manufacturers produce them as single, integrated components, leveraging additive manufacturing’s strength. Welding becomes necessary for specific applications. These include joining multiple printed sections, repairing damage, or integrating non-printed elements. Welding 3D printed titanium frames presents unique challenges. Understanding these considerations is crucial for successful hybrid designs and repairs.

FAQ

Do all 3D printed titanium frames require welding?

No, 3D printed titanium frames do not inherently require welding. Manufacturers often produce them as single, monolithic components. This process leverages additive manufacturing’s strength, eliminating the need for traditional welds in the primary structure.

When does welding become necessary for 3D printed titanium frames?

Welding becomes essential in specific situations. These include joining multiple printed sections to create larger structures. It is also necessary for repairing damaged frames or integrating non-printed elements like mounting brackets into the design.

What makes welding 3D printed titanium challenging?

Welding 3D printed titanium presents challenges due to its unique microstructure and potential residual stresses. Titanium’s high reactivity with atmospheric gases also demands an inert atmosphere. Welders require specialized expertise and precise control to achieve sound joints.

How does welding impact the properties of a 3D printed titanium frame?

Welding creates a heat-affected zone (HAZ) where the material’s microstructure changes. This can alter local mechanical properties. Welding also introduces residual stresses and potential distortion. Post-weld treatments help mitigate these effects.

Can manufacturers repair damaged 3D printed titanium frames using welding?

Yes, welding offers a viable solution for repairing damaged 3D printed titanium frames. Technicians can address cracks, breaks, or structural failures. This process extends the component’s service life, but requires careful technique due to the material’s specific characteristics.

What are the advantages of designing weld-free 3D printed titanium frames?

Eliminating welds enhances fatigue resistance and durability. It removes common failure points found in traditional welded structures. This approach also reduces manufacturing steps and inspection needs, streamlining production and improving overall product reliability.

What post-weld treatments are important for 3D printed titanium?

Post-weld heat treatments, such as stress relief at specific temperatures, are crucial. These treatments reduce residual stresses and improve microstructural homogeneity. Non-destructive testing (NDT) methods like X-ray or ultrasonic inspections then ensure weld integrity.

3D printed titanium frames typically do not require welding for their primary structural integrity. Manufacturers produce these frames as single, monolithic components. However, welding becomes essential in specific situations. These include joining multiple printed parts or repairing damage. Integrating non-printed elements also necessitates welding processes.

Key Takeaways

- 3D printed titanium frames usually do not need welding. They are made as one strong piece.

- Welding is needed to join many printed parts. It also fixes damage or adds other parts.

- Advanced methods like DMLS and SLM build strong titanium parts. They create dense, uniform structures.

- Single-piece 3D printed frames are very strong. They have no weak spots from welds.

- Welding 3D printed titanium is hard. It needs special care due to the material’s unique structure.

- Welding changes the material near the weld. Post-weld treatments help fix these changes.

- Designing frames without welds makes them stronger. It also makes them last longer and simplifies making them.

Understanding Monolithic 3D Printed Titanium Frames

How Additive Manufacturing Creates Strong Titanium Parts

Additive manufacturing revolutionizes how manufacturers create strong titanium parts. This technology builds components layer by layer. It uses precise fusion processes.

Layer-by-Layer Fusion Processes (DMLS, SLM, EBM)

Several advanced processes contribute to the strength of 3D printed titanium. Direct Metal Laser Sintering (DMLS) uses a laser to fuse metal powder particles. Selective Laser Melting (SLM) fully melts the powder, creating a dense part. Electron Beam Melting (EBM) employs an electron beam in a vacuum to melt and fuse powder. These methods precisely control material deposition and solidification.

The ADDere additive manufacturing system utilizes a laser-wire process. This system directly prints large-scale titanium components. This method allows for rapid iteration and fabrication of complex designs. It produces near-net-shaped parts. These parts require minimal finish machining. This approach leads to more efficient and stronger titanium components. It reduces material waste and machining time compared to conventional methods.

Sciaky employs Electron Beam Additive Manufacturing (EBAM) processes for titanium 3D printing. This technology is particularly effective for titanium alloys. It combines the material’s inherent advantages with the design flexibility of additive manufacturing. EBAM addresses challenges of working with titanium. These challenges include its reactivity and hardness. It provides a method for building high-precision titanium parts layer by layer.

Achieving Dense, Homogeneous Structures

These layer-by-layer fusion processes ensure the creation of dense structures. They minimize internal voids and defects. The controlled melting and solidification result in a fine, homogeneous microstructure. This microstructure contributes significantly to the material’s strength and durability. Manufacturers can achieve properties comparable to traditionally manufactured titanium.

The Inherent Strength of Single-Piece 3D Printed Titanium Frames

Single-piece 3D printed titanium frames possess inherent strength. Their manufacturing process eliminates weak points often found in assembled parts.

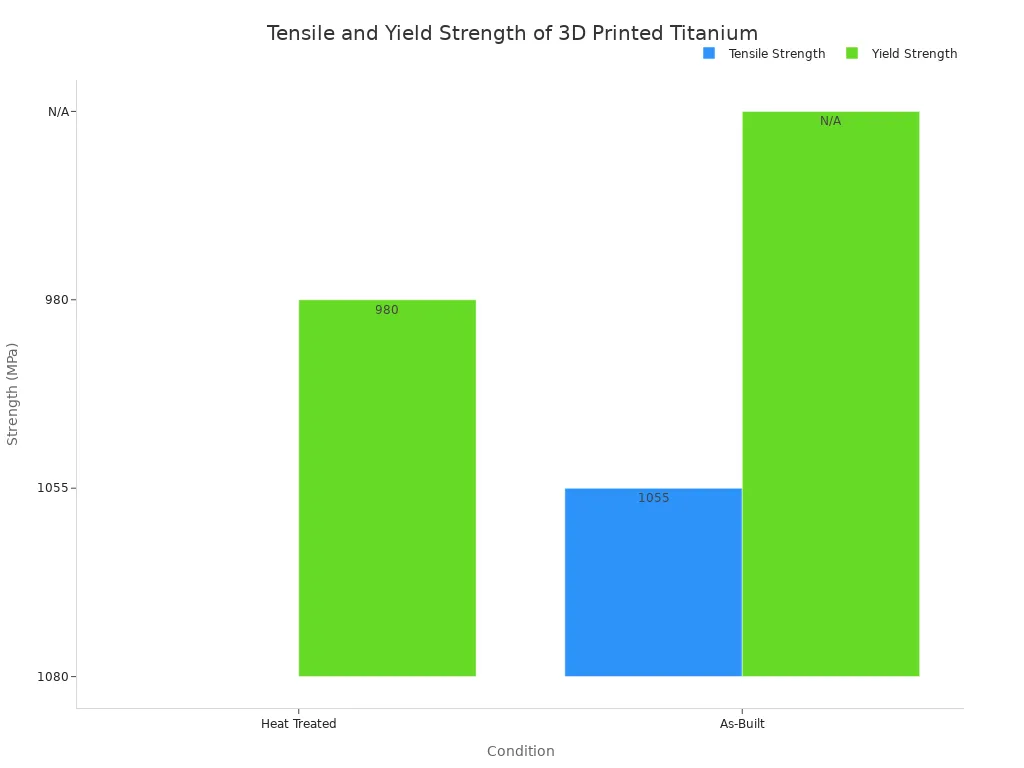

Mechanical Properties Comparable to Wrought Titanium

3D printed titanium exhibits impressive mechanical properties. These properties are often comparable to wrought titanium. Wrought titanium undergoes shaping through deformation. The additive manufacturing process creates materials with high tensile and yield strengths.

| Condition | Tensile Strength (MPa) | Yield Strength (MPa) |

|---|---|---|

| Heat Treated | 1080 | 980 |

| As-Built | 1055 | N/A |

3D printed titanium typically exhibits a tensile strength of around 1200 MPa. It has a yield strength of approximately 880 MPa. These values can vary. Specific processing methods and alloying elements influence them.

Absence of Traditional Weld Seams in Monolithic Designs

Monolithic designs eliminate traditional weld seams. Welds are often points of weakness in conventionally fabricated structures. The continuous, single-piece construction of 3D printed titanium frames enhances their overall integrity. This design reduces the risk of fatigue failure.

While 3D printed titanium alloys offer advantages like personalized customization, their fatigue strength can be weaker than traditional titanium implants. This fatigue strength links closely to porosity and surface morphology. However, surface modification technologies improve fatigue strength. Examples include shot peening or TiO2 nanotube coating. These methods enhance the service life of 3D-printed titanium alloys.

3D printed titanium components can exhibit excellent fatigue properties. Modern 3D printing techniques address previous concerns. They achieve this through microstructural optimization. It is possible to create ‘Net-AM’ microstructures. These microstructures demonstrate exceptionally high fatigue resistance. They surpass most additively manufactured and even forged titanium alloys. Post-processing methods also improve density. These methods include heat treatment and Hot Isostatic Pressing (HIP). They eliminate residual stress and enhance fatigue strength. This leads to final parts comparable to or better than traditionally forged or machined components.

When Welding Becomes Essential for 3D Printed Titanium Frames

While 3D printed titanium frames often achieve structural integrity as single, monolithic units, specific situations necessitate welding. These scenarios typically involve combining multiple components, repairing damage, or integrating non-printed elements into the frame structure.

Joining Multiple 3D Printed Components

Manufacturers often need to join multiple 3D printed components for various reasons. This approach allows for the creation of larger structures or parts with optimized properties.

Assembling Large or Modular Frame Sections

Additive manufacturing build volumes have limitations. Therefore, designers often segment large 3D printed titanium frames into smaller, manageable sections. They then assemble these sections post-printing. This modular approach allows for the production of structures exceeding the physical dimensions of a single 3D printer. For example, if a part experiences misalignment during the printing process, a visible flaw might appear where sections were intended to join. These components then require post-printing joining to achieve an acceptable production standard.

When joining large 3D printed titanium frame sections, specific welding techniques prove effective. For slip-fit parts, technicians treat them as normal mitered joints, fuse them, and then cap the weld. Butt joints require a single pass with filler material. Welders ensure settings, especially if pulsed, allow for the fusion of the entire part plug, which often demands more filler than usual. They utilize a small filler lip on titanium parts, frequently supplementing it with additional filler (e.g., .028″) for both structural integrity and aesthetics. Optimizing welding settings for each part based on its structural and aesthetic requirements is crucial. Some processes consider using fusion rings, such as a 1mm thick lip extending 1.3mm, to aid welding, even if print defects like ‘broken edges’ melt during the process. Post-weld heat treatment addresses any residual stress.

Connecting Complex Geometries Beyond Single Print Capabilities

Designers also segment complex geometries into multiple parts when a single print cannot achieve the desired intricacy or functionality. This strategy allows for the selective placement of materials to achieve specific properties. For instance, when designing components like a wrench for space station use, both strength and weight are critical. Different materials, potentially including titanium, might be printed separately and then joined. This enables a lighter handle while maintaining a strong working end. Similarly, biomedical implants require tailored functionality. For titanium implants, integrating other materials like zinc and magnesium for bone growth is necessary, while retaining titanium’s inherent strength. This involves printing different sections or materials separately and then joining them to create an implant with optimized mechanical stability and biological interaction.

Repairing Damaged 3D Printed Titanium Frames

Even robust 3D printed titanium frames can sustain damage during their operational lifespan. Welding offers a viable solution for repairing these components.

Addressing Cracks, Breaks, or Structural Failures

Welding becomes essential for addressing various forms of damage, including cracks, breaks, or other structural failures. A skilled technician can restore the frame’s integrity by carefully preparing the damaged area and applying appropriate welding techniques. This process extends the service life of the component and avoids costly replacements.

Similarities and Differences to Traditional Titanium Repair

Repairing 3D printed titanium frames shares similarities with traditional titanium welding. Both processes require an inert atmosphere to prevent contamination and oxidation, given titanium’s high reactivity. However, differences exist. The microstructure of 3D printed titanium can vary from wrought titanium, potentially influencing weldability and requiring adjustments in welding parameters. The presence of residual stresses from the additive manufacturing process also demands careful consideration during repair welding to prevent further distortion or cracking.

Integrating Non-Printed Elements into 3D Printed Titanium Frames

Hybrid manufacturing approaches often combine the benefits of 3D printing with traditional manufacturing methods. This integration frequently requires welding.

Attaching Mounting Brackets and Specialized Connectors

Many applications require the attachment of non-printed elements to 3D printed titanium frames. These elements might include mounting brackets for sensors, specialized connectors for electrical systems, or interfaces for other mechanical components. Welding provides a strong, permanent bond for these attachments, ensuring the overall functionality and reliability of the assembly.

Hybrid Manufacturing Approaches Combining Printed and Traditional Parts

Hybrid manufacturing leverages the design freedom of additive manufacturing for complex geometries and the cost-effectiveness or specific material properties of traditional parts. For example, a complex internal structure might be 3D printed, while external, simpler components are machined or cast. Welding then joins these disparate parts into a cohesive unit. This approach optimizes both performance and manufacturing efficiency.

Specific Challenges of Welding 3D Printed Titanium Frames

Welding 3D printed titanium frames presents unique challenges. These challenges stem from the material’s distinct metallurgical characteristics and the stringent technical requirements for successful joining. Welders must understand these factors to ensure the integrity and performance of the final product.

Metallurgical Differences and Weldability

The additive manufacturing process imparts specific microstructural features to titanium. These features significantly influence how the material behaves during welding.

Impact of 3D Printed Microstructure on Welding

3D printed Ti-6Al-4V samples exhibit larger primary β grains compared to wrought (rolled) samples. This structural difference leads to higher thermal conductivity in the printed material. Increased thermal conductivity results in wider welds and a faster cooling rate during the welding process. The rapid cooling limits crystallite growth in the weld metal. It also reduces the heat-affected zone (HAZ) size. The HAZ in 3D printed samples is approximately half as wide as in rolled samples. Furthermore, the higher cooling rate in 3D printed samples leads to a lower volume fraction of residual β phase in the weld metal. These microstructural variations demand careful adjustment of welding parameters.

Unique Properties of 3D Printed Titanium

3D printed titanium often possesses anisotropic properties. This means its mechanical characteristics can vary depending on the build direction. Residual stresses can also exist within the material from the layer-by-layer printing process. These unique properties can affect weld penetration, fusion, and the formation of defects. Welders must account for these inherent material characteristics to achieve sound joints.

Best Practices and Technical Requirements for Welding

Successful welding of 3D printed titanium requires adherence to strict best practices and technical specifications.

Inert Atmosphere and Contamination Control

Titanium reacts readily with atmospheric gases like oxygen and nitrogen at elevated temperatures. This reactivity can lead to embrittlement and porosity in the weld. Therefore, maintaining an inert atmosphere is paramount. Welders typically use high-purity argon gas shielding for both the weld pool and the surrounding hot metal. They also employ specialized chambers or trailing shields to prevent contamination.

Filler Material Selection and Compatibility

Selecting the correct filler material is crucial for achieving strong and ductile welds. The filler metal must be compatible with the base 3D printed titanium alloy. It should match the mechanical properties and corrosion resistance of the parent material.

| ASTM Base Metal Grade | Base metal | Recommended Filler Metal |

|---|---|---|

| Grade 1 | Unalloyed Ti CP1 | ERTi-1 |

| Grade 2 | Unalloyed Ti CP2 | ERTi-2 |

| Grade 4 | Unalloyed Ti CP4 | ERTi-4 |

| Grade 5 | Ti 6AL-4V | ERTi-5 |

| Grade 7 | Ti 0.15Pd | ERTi-7 |

Titanium Welding Wire ErTi1 Titanium Alloy Wire Grade 1 Grade 5 is marketed as suitable for ‘3D Printing Metal’. This indicates specific filler materials are developed for additive manufacturing applications.

Expertise Required for Successful Welds

Welding titanium, especially 3D printed variants, demands significant expertise. Welders must possess a deep understanding of titanium metallurgy, welding processes, and contamination control. They need specialized training and experience to consistently produce high-quality welds. Improper technique can lead to defects, compromising the structural integrity of the component.

Impact of Welding on 3D Printed Titanium Frame Properties

Welding introduces significant changes to the material properties of 3D printed titanium frames. These alterations primarily occur within the heat-affected zone (HAZ) and can influence the overall performance and longevity of the component.

Heat-Affected Zones (HAZ) and Material Alterations

The heat from welding creates a localized area known as the heat-affected zone. This zone experiences microstructural changes without melting.

Changes in Local Mechanical Properties

The HAZ in welded 3D printed titanium differs from that in wrought titanium.

- 3D Printed Titanium HAZ:

- Composed of fine equiaxed grains.

- Microhardness is lower than that of wrought welds. This is due to finer microstructure grains.

- In some cases, the HAZ microstructure closely resembles the fusion zone. This makes differentiation difficult.

- Wrought Titanium HAZ:

- Primarily consists of blocky α and some untransformed β and α phases near the base metal.

- Near the fusion zone, it exhibits an α martensitic microstructure. This leads to higher hardness in that region compared to the base metal.

- Microhardness is generally higher than in additively manufactured welds.

- It shows a clear transition. Acicular martensite decreases away from the weld center. Grain boundary α phase forms.

In friction stir welded electron beam printed Ti-6Al-4V plates, the thermo-mechanically affected zone (TMAZ) showed the highest hardness. This observation deviates from the typical trend. The stir zone (SZ) usually shows the highest hardness. The reduction in hardness/strength in the SZ was attributed to the presence of tungsten-cobalt rich particles and coarser β grains. These formed a soft zone.

Potential for Residual Stresses and Distortion

Welding introduces thermal gradients. These gradients can lead to residual stresses within the material. These stresses can cause distortion in the frame. They can also reduce the fatigue life of the component. Careful control of welding parameters helps minimize these adverse effects.

Post-Weld Treatments and Quality Assurance

Post-weld treatments are crucial for restoring optimal properties and ensuring the integrity of welded 3D printed titanium frames.

Stress Relief and Heat Treatment Considerations

Post-weld heat treatments at 650 °C and 750 °C effectively mitigate residual stresses in titanium welds. Specifically, a 750 °C heat treatment leads to more complete stress relaxation compared to a 650 °C treatment. In as-welded conditions, peak tensile residual stress in the weld center zone (WCZ) was 709.2 MPa. After 650 °C treatment, this was reduced to 114.4 MPa. Following 750 °C treatment, residual stress throughout the entire weld, including the WCZ, was significantly reduced. This indicates the superior effectiveness of the higher temperature.

Post-weld heat treatment (PWHT) is a recognized mitigation strategy for reducing residual stresses in titanium welds. Some studies show reductions of over 90%. Beyond stress relief, PWHT also contributes to microstructural homogenization. It enhances mechanical properties. This approach addresses high residual stresses. These stresses can significantly impact fatigue crack propagation. They can compromise fatigue life predictions.

Non-Destructive Testing (NDT) for Weld Integrity

Non-destructive testing (NDT) methods are essential for evaluating weld quality without damaging the component.

- X-ray scanning is used for post-build non-destructive testing. It detects internal flaws like porosity in 3D printed titanium frames.

- CT scanning is used for post-build non-destructive testing. It detects internal flaws like porosity in 3D printed titanium frames.

After welding, additional NDT methods ensure weld integrity.

- X-ray methods are used for post-weld non-destructive testing.

- Ultrasonic methods are used for post-weld non-destructive testing.

Design Considerations for Weld-Free 3D Printed Titanium Frames

Designers prioritize specific principles when creating 3D printed titanium frames without welds. These considerations leverage the unique capabilities of additive manufacturing. They aim to produce strong, efficient, and durable components.

Optimizing Designs for Monolithic Production

Optimizing designs for monolithic production focuses on creating single, integrated parts. This approach eliminates the need for joining separate components.

Maximizing Structural Integrity Through Integrated Design

Integrated design significantly enhances structural integrity. Additive manufacturing allows for the creation of complex, rider-specific geometries. This approach reduces welding, thereby minimizing assembly failure points. It also improves overall strength and structural stability. Computational tools like topology optimization are crucial. They optimize structural elements, placing material only where necessary. This creates strong yet lightweight components. Metal additive manufacturing facilitates complex internal geometries. Traditional methods like stamping or casting cannot achieve these. This further contributes to optimized structures.

Leveraging Design Freedom for Complex Geometries

Additive manufacturing offers unparalleled design freedom. Designers can combine multiple assembly components into a single, monolithic printed part. This reduces part count and eliminates joints or fasteners. It also improves structural efficiency and integrates functionality. Topology optimization helps create organic, efficient structures with significant weight savings. Designers incorporate complex internal features like lattices for weight reduction and tailored stiffness. They also include conformal channels for fluids or wiring. This requires careful consideration for powder removal. Designs focus on functional requirements, such as load paths and stiffness, rather than traditional manufacturing constraints. The complexity of features, internal channels, and complex curvatures has minimal impact on AM production costs. Designers also aim for self-supporting angles, typically greater than 45° from horizontal. This reduces material cost, print time, and post-processing. They adhere to AM process limits for minimum wall thickness (e.g., 0.4-1.0 mm) and hole/pin diameters (e.g., >0.5-1.0 mm). This ensures reliable production and avoids distortion or sealing issues.

Advantages of Eliminating Welds in 3D Printed Titanium Frames

Eliminating welds offers significant benefits for the performance and manufacturing of 3D printed titanium frames.

Enhanced Fatigue Resistance and Durability

The absence of welds directly contributes to enhanced fatigue resistance and durability. Issues in traditional titanium frames typically occur at the welds, for example, at the bottom bracket and rear dropouts. Problems can also arise where tubing has been cold-worked, such as bent, crimped, or shaped. These areas are susceptible to human error. Cracking in welds can develop over time. However, it is usually noticeable before catastrophic failure. Advanced manufacturing technologies, including 3D printing, eliminate the risks associated with welding. This results in a more reliable and structurally sound product. It directly contributes to the overall durability and lifespan of 3D printed titanium frames by removing a common point of failure.

Reduced Manufacturing Steps and Inspection Needs

Monolithic production significantly reduces manufacturing steps. It eliminates the need for separate welding processes and subsequent inspections. This streamlines the production workflow. It also lowers labor costs and accelerates time to market. The inherent integrity of a single-piece component minimizes the need for extensive post-production quality checks related to weld integrity.

3D printed titanium frames do not inherently require welding. Manufacturers produce them as single, integrated components, leveraging additive manufacturing’s strength. Welding becomes necessary for specific applications. These include joining multiple printed sections, repairing damage, or integrating non-printed elements. Welding 3D printed titanium frames presents unique challenges. Understanding these considerations is crucial for successful hybrid designs and repairs.

FAQ

Do all 3D printed titanium frames require welding?

No, 3D printed titanium frames do not inherently require welding. Manufacturers often produce them as single, monolithic components. This process leverages additive manufacturing’s strength, eliminating the need for traditional welds in the primary structure.

When does welding become necessary for 3D printed titanium frames?

Welding becomes essential in specific situations. These include joining multiple printed sections to create larger structures. It is also necessary for repairing damaged frames or integrating non-printed elements like mounting brackets into the design.

What makes welding 3D printed titanium challenging?

Welding 3D printed titanium presents challenges due to its unique microstructure and potential residual stresses. Titanium’s high reactivity with atmospheric gases also demands an inert atmosphere. Welders require specialized expertise and precise control to achieve sound joints.

How does welding impact the properties of a 3D printed titanium frame?

Welding creates a heat-affected zone (HAZ) where the material’s microstructure changes. This can alter local mechanical properties. Welding also introduces residual stresses and potential distortion. Post-weld treatments help mitigate these effects.

Can manufacturers repair damaged 3D printed titanium frames using welding?

Yes, welding offers a viable solution for repairing damaged 3D printed titanium frames. Technicians can address cracks, breaks, or structural failures. This process extends the component’s service life, but requires careful technique due to the material’s specific characteristics.

What are the advantages of designing weld-free 3D printed titanium frames?

Eliminating welds enhances fatigue resistance and durability. It removes common failure points found in traditional welded structures. This approach also reduces manufacturing steps and inspection needs, streamlining production and improving overall product reliability.

What post-weld treatments are important for 3D printed titanium?

Post-weld heat treatments, such as stress relief at specific temperatures, are crucial. These treatments reduce residual stresses and improve microstructural homogeneity. Non-destructive testing (NDT) methods like X-ray or ultrasonic inspections then ensure weld integrity.