Yes, manufacturers successfully metal injection mold titanium. This process offers unique advantages, despite inherent challenges. This guide explores the feasibility, process, benefits, and applications of Titanium Metal Injection Molded parts. This advanced manufacturing technique consistently produces complex components. It provides innovative solutions for demanding industries, leveraging titanium’s superior properties.

Key Takeaways

- Titanium can be metal injection molded, offering a way to make complex parts.

- MIM combines plastic molding and powdered metal to create precise metal components.

- Titanium MIM faces challenges like high melting points and material costs.

- New methods and special equipment help overcome these difficulties.

- Titanium MIM parts are strong, light, and resist rust well.

- This process is good for medical, aerospace, and electronic parts.

- MIM titanium saves money and reduces waste for complex designs.

- MIM titanium parts are almost as good as titanium made in traditional ways.

Understanding Metal Injection Molding (MIM)

What is MIM?

Overview of the MIM Process

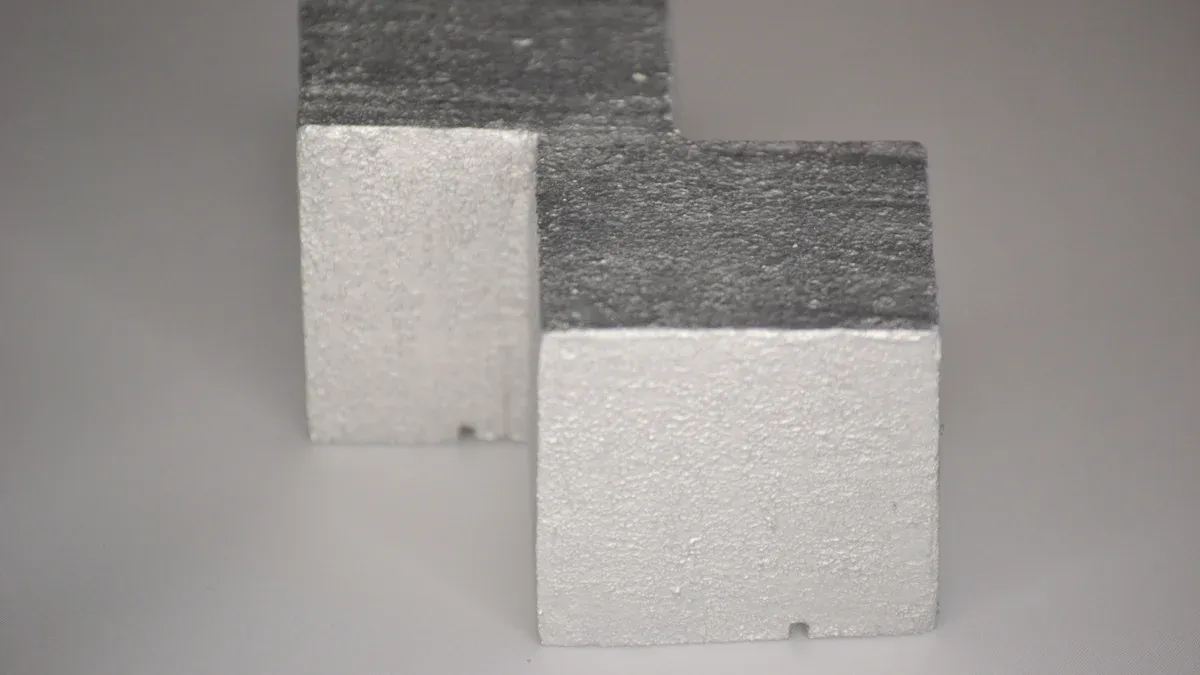

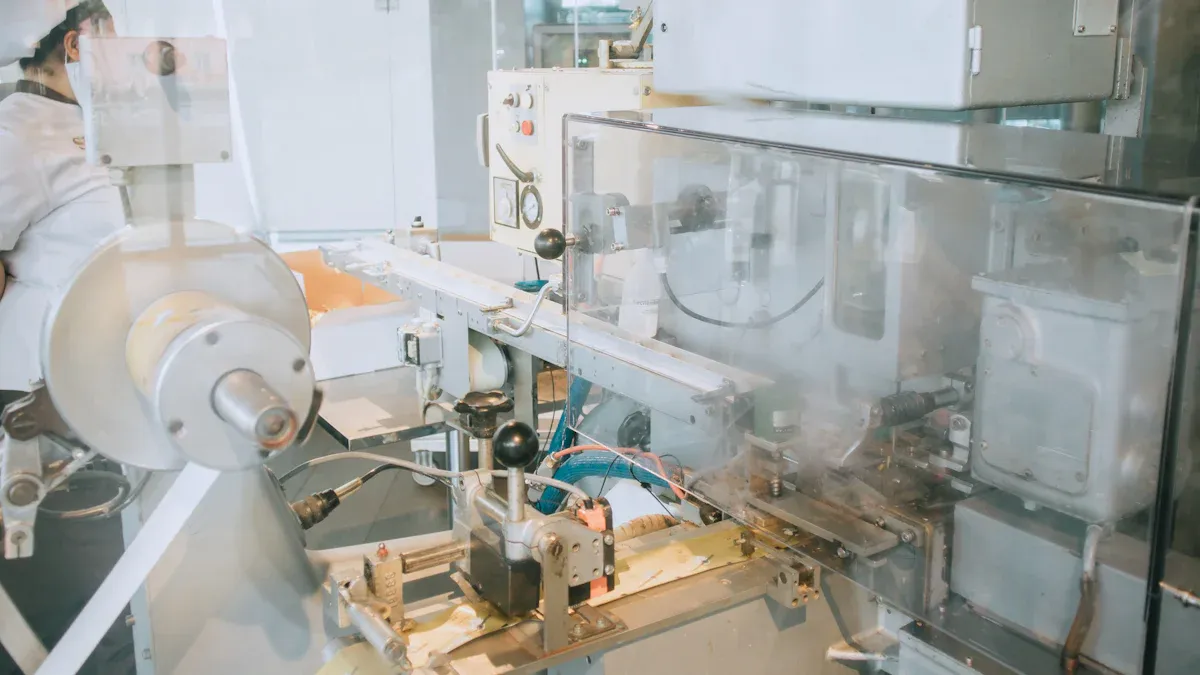

Metal Injection Molding (MIM) combines two established manufacturing techniques: plastic injection molding and powdered metallurgy. This process creates complex metal parts with high precision. First, fine metal powder mixes with a polymer binder to form a feedstock. Manufacturers then inject this feedstock into a mold cavity, similar to plastic injection molding. After molding, a debinding step removes the binder. Finally, a sintering process heats the part to a high temperature, fusing the metal particles and densifying the component. This results in a solid, high-performance metal part.

Why Powdered Metal is Used in Injection Molding

Powdered metal is crucial for injection molding because it allows for shaping intricate designs. Traditional metalworking methods often struggle with these complex geometries. Using fine metal powders enables the feedstock to flow like plastic, filling tiny details within the mold. After the binder removal and sintering, the metal particles bond together. This creates a dense, strong component with properties comparable to wrought metals. This method also minimizes material waste, especially important for expensive materials.

Advantages of MIM for Complex Geometries

Design Freedom and Intricate Part Production

MIM offers significant design freedom, allowing engineers to create highly complex and intricate parts. It produces designs with thin walls, fine details, and complex internal features. This capability often eliminates the need for assembling multiple components. MIM can integrate several parts into a single, unified piece. This simplifies manufacturing and improves part integrity.

Cost-Effectiveness for Mass Production

MIM proves highly cost-effective for mass production. The process achieves high material utilization, often up to 98%. This significantly reduces waste compared to traditional machining methods. Unused feedstock can also be recycled, further enhancing efficiency. MIM produces near-net-shape components, minimizing or eliminating costly post-machining steps. Parts achieve excellent dimensional accuracy. Features like logos or part numbers can be integrated during the molding process. Multi-cavity molds enable the simultaneous production of many parts per cycle. This makes MIM ideal for high-volume manufacturing, lowering energy use and labor costs per part while maintaining consistent quality.

The Feasibility of Titanium Metal Injection Molded Parts

Why Titanium MIM is Challenging

High Melting Point and Reactivity of Titanium

Titanium presents inherent difficulties for Metal Injection Molding due to its unique material properties. It possesses an exceptionally high melting point, approximately 1668 °C (3034 °F). This characteristic demands extremely high temperatures during the sintering phase, making the process energy-intensive and challenging to control precisely. Furthermore, titanium is highly reactive, especially at elevated temperatures. It readily forms brittle compounds when it reacts with oxygen, nitrogen, and carbon. These reactions significantly degrade the mechanical properties of the final part. Therefore, manufacturers must maintain strict atmosphere control, typically using a vacuum or inert gas, throughout the processing stages.

Specific Characteristics of Titanium Powder

Titanium powder itself introduces specific challenges. Fine titanium powder can be pyrophoric, meaning it may self-ignite in air. This necessitates extremely careful handling and storage procedures. The morphology, or shape, and the particle size distribution of the titanium powder critically influence the flowability of the feedstock and the final density of the molded part. Irregularly shaped powders, such as those produced by the Hydride-Dehydride (HDH) process, can lead to agglomeration and higher oxygen content. Conversely, spherical powders offer superior flow characteristics but come with a higher cost.

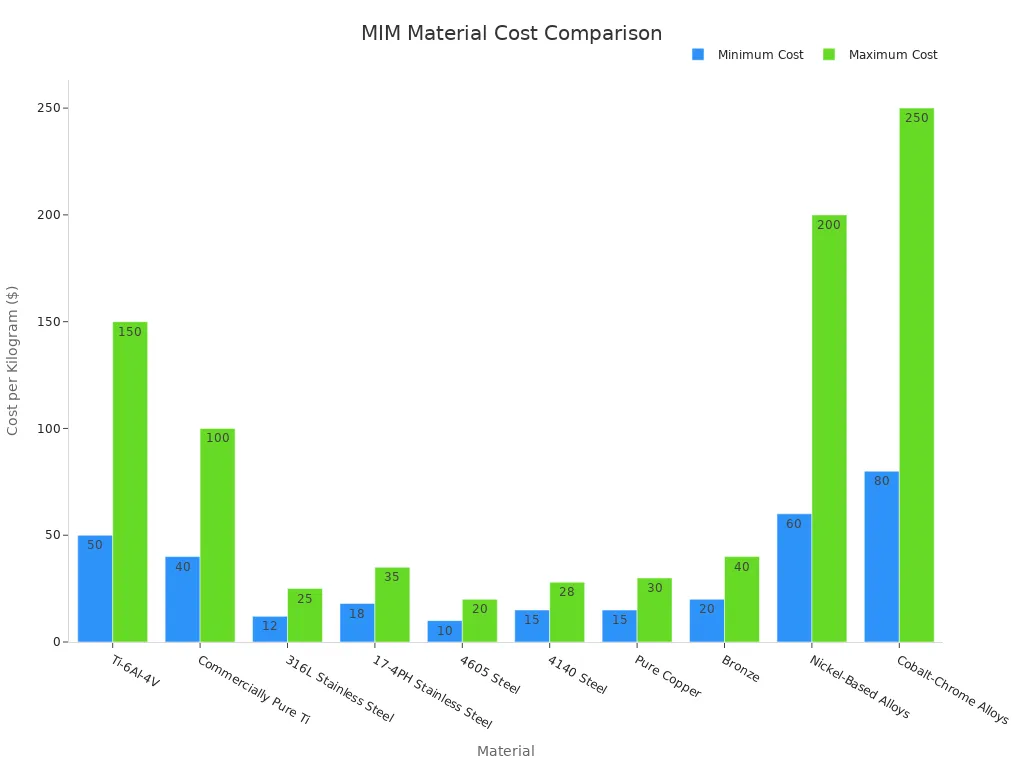

Material Cost Implications

The material cost of titanium powder significantly impacts the overall feasibility of Titanium Metal Injection Molded parts. Titanium powder is considerably more expensive than many other common MIM materials. This higher raw material cost directly contributes to the increased production cost of titanium components.

The table below illustrates the typical material costs for various MIM powders:

| Material | Cost per Kilogram ($) |

|---|---|

| Ti-6Al-4V | 50 – 150 |

| Commercially Pure Ti | 40 – 100 |

| 316L Stainless Steel | 12 – 25 |

| 17-4PH Stainless Steel | 18 – 35 |

| 4605 Steel | 10 – 20 |

| 4140 Steel | 15 – 28 |

| Pure Copper | 15 – 30 |

| Bronze | 20 – 40 |

| Nickel-Based Alloys | 60 – 200 |

| Cobalt-Chrome Alloys | 80 – 250 |

For instance, Ti-6Al-4V powder typically costs between $50 and $150 per kilogram. Commercially Pure Titanium ranges from $40 to $100 per kilogram. These prices are substantially higher than those for common MIM materials like stainless steel alloys (e.g., 316L at $12–$25/kg) and low alloy steels (e.g., 4605 at $10–$20/kg). While specialty alloys such as nickel-based and cobalt-chrome alloys can have comparable or higher costs, titanium remains a premium material in the MIM landscape.

Key Challenges in Titanium MIM

Titanium Powder Production and Handling

Producing and handling titanium powder for MIM applications presents several critical challenges. Contamination by oxygen and carbon poses significant concerns. Carbon, often present in binders, can be absorbed during high-temperature steps like thermal debinding. Oxygen contamination can originate from the powder itself, from sintering supports (e.g., Y2O3 or ZrO2), and from the sintering atmosphere. While storing and handling powder below 200°C is not critical, rapid oxidation begins above 400°C. The interstitial content of the powder and the sintering atmosphere are most critical for preventing contamination.

Commercial titanium-based MIM feedstock is less available compared to stainless steel or cobalt-based materials. Although pure titanium feedstock (grade 4) was initially common, a variety of Ti-6Al-4V feedstocks are now available. Many commercial MIM suppliers produce feedstock in-house due to limited commercial options.

Powder cost and purity vary significantly. ‘Pure’ powders, characterized by low oxygen/carbon content and few residuals, are expensive and typically spherical. Manufacturers produce these powders through inert gas atomization, plasma atomization, or plasma rotating electrode processing. Lower-cost powders often have irregular shapes, may exhibit agglomerations, and are produced by mechanical milling, such as the Hydride-Dehydride (HDH) process. HDH powders generally have higher oxygen content due to passivation steps and high processing temperatures, which also leads to agglomeration.

Proper powder handling is essential. Passivation steps are included in HDH powder processing to avoid self-ignition and burning. Agglomeration is typical for HDH powders. The choice of powder (spherical versus irregular, pure versus HDH) impacts mechanical properties, flowability, and cost. Spherical powders offer better flowability and higher sintering activity but are more expensive. However, their availability and decreasing prices are improving due to advancements in additive manufacturing.

Equipment cleanliness is also paramount. Manufacturers must prevent contamination from other materials, especially steel powder, to avoid brittle or low-melting phases in the final titanium part. Thorough cleaning of injection molding machine parts in contact with feedstock is crucial when changing materials. The clearance of the backflow valve of the screw should be larger than the maximum powder particle size to prevent fretting.

Binder Selection and Feedstock Formulation

Binder selection and feedstock formulation are crucial steps in titanium MIM. Blending titanium powder with appropriate binders is essential. Manufacturers must carefully control the feedstock composition. They use high-quality titanium powders with tight particle size distributions. Minimizing impurities such as oxygen and chlorine in the titanium powder is also critical.

Binder systems must allow for two-step debinding, typically involving solvent and thermal stages. Risks of oxidation and carbonization exist during thermal debinding, especially if the second binder component contains oxygen or decomposes at high temperatures. The thermal degradation temperature should be as low as possible to minimize contamination, ideally between 400°C and 500°C. The ratio of binder components affects green part strength and the acceptable contamination level.

Debinding Process Control for Titanium

The debinding process removes the binder from the green part. This step requires meticulous control to prevent defects like cracks or distortion. For titanium, the debinding process carries significant risks of oxidation and carbonization, particularly during thermal debinding. The decomposition products of the binder must not react with the titanium powder. The debinding temperature and atmosphere are critical parameters that manufacturers must carefully manage.

Sintering Parameters and Atmosphere Management

Sintering represents the most critical step for achieving final density and properties in titanium MIM parts. It is also the most susceptible to oxygen contamination. While complete avoidance of contamination is impossible, manufacturers can minimize it by using a high vacuum (at least 10-2 Pa) or a high-purity argon atmosphere. However, an argon atmosphere may lead to lower density due to gas trapping. Using powder with low oxygen content, such as ELI (Extra-Low Interstitial) Ti-6Al-4V, is also important. The oxygen difference between the powder and the sintered part can be limited to about 0.05 wt%, but values up to 0.1 wt% are possible.

Optimizing sintering parameters involves a compromise between achieving low residual porosity and maintaining small grain sizes. High sintering temperatures and long hold times generally lead to higher density, strength, and ductility. However, these conditions also promote grain coarsening, which can be detrimental to certain properties. Sintering above the beta-transus temperature in the single-phase beta region, common for pure titanium and Ti-6Al-4V, promotes grain growth. Sometimes, sintering at a lower temperature for a longer time proves more beneficial than a brief high-temperature hold. Typical sintering temperatures are around 1300°C with a 2-hour hold time.

Producing titanium via powder injection molding with competitive properties requires a detailed scientific foundation. The production process details significantly impact properties, with every step being important. Key focus areas linking powder and processing include density, purity, alloying, and microstructure. The role of impurities and the inability to remove them during sintering necessitate careful attention to starting alloy powders and binder compositions.

Innovations Overcoming Titanium MIM Challenges

Advanced Binder Systems and Feedstock Development

Researchers continuously develop new binder systems. These advanced systems offer improved flowability, higher green strength, and cleaner removal during debinding. Feedstock development focuses on optimizing powder loading and binder composition. This ensures consistent part quality and minimizes defects in the final titanium components.

Specialized Vacuum Sintering Techniques

Advanced vacuum furnaces achieve ultra-high vacuum levels. These furnaces effectively prevent contamination during the critical sintering phase. Precise temperature control and rapid heating/cooling cycles optimize the microstructure and mechanical properties of the titanium parts.

Optimized Debinding Methods

New debinding methods, including catalytic and supercritical fluid debinding, reduce processing time and minimize contamination risks. These innovative methods ensure complete binder removal without compromising the integrity of the titanium part.

Dedicated Equipment for Titanium Metal Injection Molded Production

Manufacturers design specialized equipment specifically for Titanium Metal Injection Molded production. This equipment features inert atmospheres, high-purity materials, and precise process control. Dedicated production lines prevent cross-contamination from other metals, ensuring the high purity required for critical titanium components.

The Titanium Metal Injection Molded Process: A Step-by-Step Guide

Titanium Powder Preparation

Characteristics and Requirements of Titanium Powder

Successful Titanium Metal Injection Molded (Ti-MIM) parts begin with meticulously prepared titanium powder. Manufacturers must ensure the powder meets stringent requirements for particle size distribution, particle shape, and interstitial levels. Low initial oxygen and carbon levels are crucial because removing these impurities during processing is difficult. Ti-MIM processing typically adds 0.02% to 0.1% interstitials. For example, starting with 0.2 wt% oxygen in the powder can result in a final sintered product with approximately 0.3 wt% oxygen with good practices. While higher interstitial content might improve wear resistance for applications like watch cases, medical implant applications demand very low oxygen and carbon levels. Achieving these low levels through Ti-MIM remains challenging.

The table below outlines critical characteristics and their typical requirements for titanium powder in MIM:

| Characteristic | Requirement/Range |

|---|---|

| Particle size distribution | Quantified by median particle size; typically 30 to 60 µm median particle size, below 45 µm for spherical powders, or -325 mesh |

| Particle shape | Quantified by tap density; deagglomerated spheres, high tap density (60% to 62% of pycnometer density) |

| Interstitial levels | Quantified by oxygen and carbon levels; low initial oxygen level (0.15 wt % maximum), low initial carbon level (0.04 wt % maximum) |

| Other requirements | Deagglomerated, pore-free powders (dense discrete particles without entrapped gas pockets) |

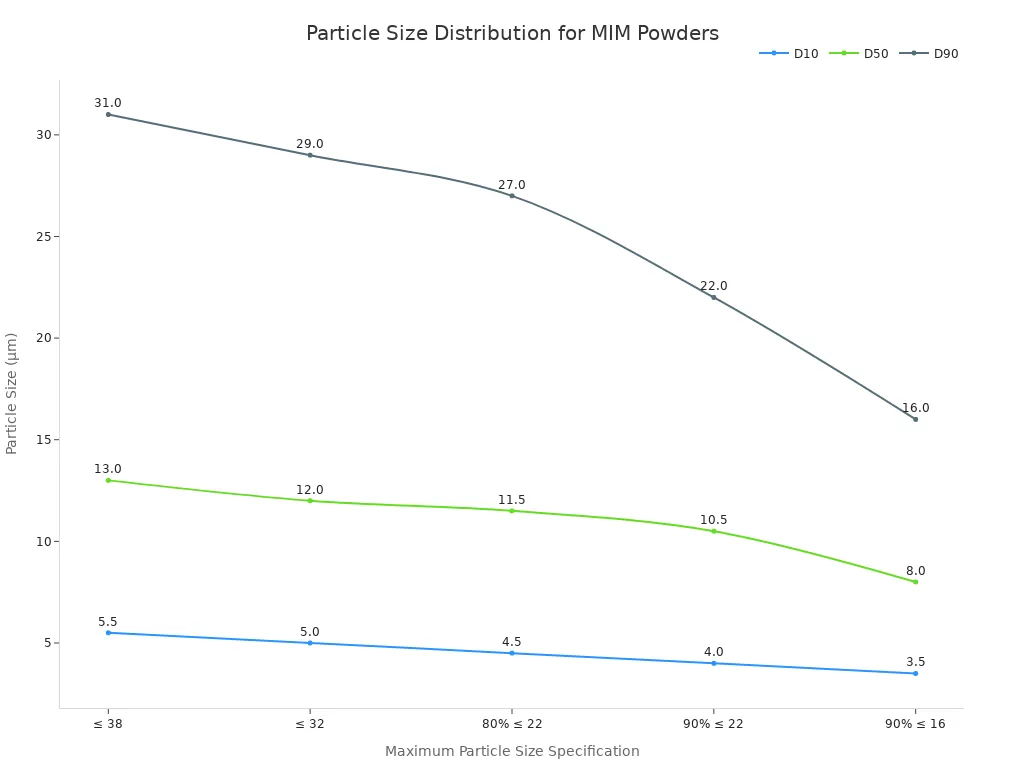

Particle Size and Morphology Considerations

Particle size distribution significantly influences MIM processing. It affects flowability, packing density, and green strength. Fine powders, such as Ti64, improve mold filling. Coarser powders can enhance flow characteristics. Achieving the correct particle size distribution is essential for producing defect-free parts. Gas atomization is a preferred method for producing spherical particles with controlled sizes. These particles offer excellent flowability and sintering behavior, which benefits MIM. Different preparation methods, like gas and water atomization, result in varied particle shapes and sizes. Gas atomization yields spherical particles with narrow size distributions. Water atomization often produces irregularly shaped particles. Surface characteristics, including morphology, surface area, and chemical composition, are also vital. They affect the powder’s interaction with the binder material, debinding, sintering behavior, and the final surface finish and dimensional stability of the molded parts. Surface area measurement helps optimize these characteristics for better binder interaction and improved part quality.

The chart below illustrates typical particle size distributions for Metal Injection Molding (MIM) powders:

Mixing and Granulation for Titanium MIM

Binder Selection and Its Role in Feedstock

Binder selection is crucial for achieving homogeneous titanium feedstock in MIM. Manufacturers tailor binder components to reduce interparticle friction. This improves the flowability of irregular powders. A new binder system, for example, consists of water-soluble polyethylene glycol (PEG) as the main component. It also includes poly (propylene carbonate) (PPC) and poly (methyl methacrylate) (PMMA) as backbone components. This system was developed for titanium-MIM processing. It demonstrated improved rheological properties. It also allowed for higher solid loadings, especially for irregular HDH titanium powder feedstocks. The interactions between polymeric components in the binder provided compatibility. This ensured suitability for thermal processing and enhanced green strength after debinding.

Creating Homogeneous Titanium Feedstock

Creating homogeneous titanium feedstock is a critical step. Manufacturers mix the carefully selected titanium powder with the binder system. This process occurs under controlled temperature and shear conditions. The goal is to achieve a uniform distribution of powder particles within the binder. This prevents agglomerates or voids. Inhomogeneous feedstocks, often resulting from improper binder selection or mixing, can lead to poor rheological properties. They can also cause void formation, density variation, and poor dimensional stability of molded green parts. The resulting mixture, known as feedstock, must possess specific rheological properties. These properties ensure it flows consistently into the mold cavity during injection molding.

Injection Molding of Titanium

Tooling Considerations for Titanium Parts

Tooling design is paramount for successful injection molding of titanium parts. Manufacturers must consider several factors to ensure part quality and process efficiency.

- Wall Thickness: Maintain uniform wall thickness, typically between 1 mm and 6 mm. Avoid sections greater than 12.5 mm. This ensures uniform shrinkage and minimizes warping during sintering.

- Parting Lines and Ejector Pins: Design parting lines on non-functional or less visible surfaces. Position ejector pins in non-functional areas or use sleeve ejection.

- Draft Angles: Draft angles are often not necessary due to wax mold release. However, 0.5° to 2° may be beneficial for high aspect ratios.

- Surface Features (Fillets and Radii): Add fillets and radii of 0.4–0.8 mm to reduce stress. This also improves material flow and prevents defects. Manufacturers can easily integrate decorative features.

- Gating and Flow Considerations: Place gates at the thickest section for balanced flow. This minimizes voids and sink marks. Use multiple gates for complex parts.

- Holes, Slots, and Undercuts: Design holes and slots perpendicular to the parting line. MIM allows for molding undercuts with collapsible cores and direct molding of threads.

- Sintering Effects (Drag and Sag): Account for 15-20% shrinkage in mold design. Prevent sag in unsupported features by designing supports or gussets.

- Titanium alloys (e.g., Ti-6Al-4V) require controlled oxygen-free debinding and sintering conditions. Materials with lower flowability, like some titanium alloys, may require more energy and time for injection. This impacts tooling design for pressure and cycle time.

Molding Parameters and Process Control

Precise control of molding parameters is essential during the injection molding stage. This forms the feedstock into a ‘green part’ with the desired shape and dimensions.

- Molding Temperature: This parameter affects feedstock viscosity and flow.

- Injection Pressure: It controls mold filling and part density.

- Holding Pressure: This compensates for shrinkage during cooling.

- Injection Speed: It influences mold filling, weld lines, and surface finish.

- Cooling Time: This determines part solidification and cycle time.

- Mold Design: Critical aspects include gate location, runner system, venting, and cooling channels.

- Part Ejection: Minimize stress and deformation during removal.

- Machine Parameters: These include screw speed, back pressure, and clamp force.

- Green Part Density: Manufacturers monitor consistency and uniformity.

- Dimensional Accuracy: They ensure the part meets specified tolerances.

Debinding Titanium Components

Methods for Binder Removal (Thermal, Solvent, Catalytic)

After injection molding, the ‘green part’ contains a significant amount of binder. Manufacturers must remove this binder before sintering. This process, called debinding, prepares the part for densification. Binder removal in Metal Injection Molding (MIM) often occurs during the sintering process itself. The component heats, causing the binder to burn or evaporate. The binder must burn or evaporate cleanly. It should not leave contamination or form gas bubbles. These could damage the structure. The binder also must not react with the metal, especially during heating. Reactions accelerate at higher temperatures.

Several methods exist for binder removal:

- Thermal Debinding: This method uses heat to decompose and evaporate the binder.

- Solvent Debinding: This method immerses the part in a solvent. This dissolves a portion of the binder.

- Catalytic Debinding: This method uses a gaseous catalyst to chemically break down the binder.

Each method has specific advantages depending on the binder system and material. Curing is another method. It involves drying the binder and solidifying the part using heat or ultraviolet light. This increases the binder’s strength. It also prepares the part for subsequent processing.

Importance of Controlled Debinding for Titanium

Controlled debinding is especially critical for titanium components. Titanium’s high reactivity means it easily forms brittle compounds with oxygen and carbon. These elements are often present in binder residues or decomposition products. Incomplete binder removal or uncontrolled debinding can lead to carbon contamination. This significantly degrades the mechanical properties of the final part. Manufacturers must carefully manage the debinding atmosphere. They often use inert gases or vacuum to prevent oxidation. Precise temperature ramps also ensure gradual binder removal. This avoids defects like cracks or blisters in the delicate ‘brown part’.

Sintering Titanium Metal Injection Molded Parts

Achieving Final Density and Properties

Sintering is the most crucial step in the Metal Injection Molding process. It transforms the porous ‘brown part’ into a dense, solid metal component. During sintering, the part heats to a temperature below its melting point. This causes the metal particles to fuse together. The primary goals are to eliminate porosity, increase density, and enhance strength. This process significantly improves the mechanical properties of the part. It makes the part suitable for functional applications. Achieving high density, typically 95-99.5% of theoretical density, is vital for optimal performance.

Vacuum Sintering for Titanium Alloys

Titanium’s high reactivity necessitates specialized sintering conditions. Vacuum sintering is the preferred method for titanium alloys. A high vacuum prevents reactions between titanium and atmospheric gases like oxygen and nitrogen. These reactions would form brittle oxides and nitrides. These compounds severely compromise the material’s ductility and strength. Vacuum furnaces maintain extremely low pressures. This ensures a clean environment for the titanium particles to bond. This method minimizes contamination. It preserves the inherent properties of titanium.

Temperature and Time Profiles for Optimal Sintering

Optimizing the temperature and time profiles during sintering is essential. These parameters directly influence the final microstructure and mechanical properties. Manufacturers carefully select sintering temperatures. These temperatures are typically around 1200°C to 1350°C for titanium alloys. The specific temperature depends on the alloy composition. A carefully controlled heating rate prevents thermal shock. A specific hold time at the peak temperature allows sufficient time for particle diffusion and densification. Too short a hold time results in incomplete densification. Too long a hold time can lead to excessive grain growth. This negatively impacts ductility and fatigue resistance. Cooling rates also require control. They influence the final phase transformations and residual stresses within the part.

Post-Sintering Operations for Titanium

Heat Treatment for Property Enhancement

After sintering, manufacturers often perform additional heat treatments. These treatments further enhance the mechanical properties of Titanium Metal Injection Molded components. Vacuum heat treatment is a common method. It lifts material performance by refining the microstructure. Laser hardening targets specific areas. It heats the surface to change its structure into harder martensite. This improves wear resistance. Tempering heats steel below its melting point. This eases stress and improves internal structure. It balances strength with flexibility. It also increases wear resistance. Annealing makes metals softer, more pliable, and easier to machine. It eases internal stresses.

Hot Isostatic Pressing (HIP) is another critical post-sintering treatment. HIP applies high pressure and temperature simultaneously. This eliminates internal porosity. It significantly increases density. It also improves mechanical properties. HIP enhances fatigue life and overall structural integrity. Solution annealing and aging are also used. These processes induce controlled microstructural changes. They further enhance strength and other specific properties.

Surface Finishing and Machining of MIM Titanium

Sintered titanium parts often require surface finishing or machining. This achieves final dimensional tolerances and surface quality. MIM produces near-net-shape parts. This minimizes the need for extensive post-machining. However, some applications demand tighter tolerances or specific surface finishes. Grinding, polishing, or electrical discharge machining (EDM) can achieve these requirements. Surface treatments like anodizing or passivation can also improve corrosion resistance or biocompatibility. These operations ensure the Titanium Metal Injection Molded part meets all functional and aesthetic specifications.

Benefits of Titanium Metal Injection Molded Components

Cost-Effectiveness for Complex Titanium Geometries

Titanium Metal Injection Molded parts offer significant cost advantages, especially for intricate designs. This method reduces the need for extensive machining. It also minimizes material waste.

Reduced Machining and Material Waste

Traditional manufacturing methods often involve significant material removal. This generates considerable waste, particularly with expensive materials like titanium. MIM produces parts very close to their final shape. This is known as near-net-shape production. It drastically reduces the amount of material that needs removal. This leads to less scrap and lower material costs. The process also uses material efficiently, often achieving up to 98% utilization.

Economic Production of Intricate Titanium Parts

MIM is highly economical for mass production of complex titanium parts. It eliminates many costly secondary operations. These operations include welding, brazing, or assembly. The ability to produce multiple parts simultaneously in multi-cavity molds further enhances cost-effectiveness. This makes MIM a preferred choice for high-volume manufacturing of small, complex titanium components.

Design Freedom with Titanium MIM

MIM provides engineers with exceptional design freedom. It allows for the creation of highly complex and intricate titanium parts.

Ability to Create Complex Shapes and Features

MIM enables the creation of complex geometries and unique shapes. These are often difficult or impossible to achieve with traditional machining. Manufacturers can produce parts with dimensional tolerances of ±0.3%. Further machining can achieve even tighter tolerances. This makes MIM ideal for precision applications. It allows for features like undercuts, internal threads, and complex curves.

Integration of Multiple Components into Single Parts

MIM allows for combining multiple parts into a single component. This eliminates the need for fasteners, adhesives, soldering, or welding. Such integration reduces overall weight and cost. It also improves part integrity and reliability. MIM achieves high shape complexity. It suits components with a wide range of specifications, from 20 to over 250. The process also offers flexibility in surface finishes, from matte to highly polished, and various color options.

Excellent Material Properties of MIM Titanium

MIM titanium components retain the superior material properties of wrought titanium. This makes them suitable for demanding applications.

High Strength-to-Weight Ratio

MIM titanium parts exhibit an excellent strength-to-weight ratio. This characteristic is crucial for applications where weight reduction is critical. These include aerospace and medical devices. MIM Ti-6Al-4V (UNS R56400) is particularly noted for this property. While the fatigue performance of MIM components is typically 20-30% lower than wrought counterparts, post-processing treatments like hot isostatic pressing can reduce this gap to 10-15%.

Superior Corrosion Resistance

Titanium is renowned for its outstanding corrosion resistance. MIM titanium parts maintain this property. They resist degradation in harsh environments. This includes exposure to saltwater, bodily fluids, and various chemicals. This makes them ideal for marine, chemical processing, and medical applications.

Biocompatibility for Medical Applications

Titanium’s biocompatibility is a key advantage. MIM titanium parts are non-toxic and do not cause adverse reactions in the human body. This makes them highly suitable for medical and dental implants. Their ability to form complex anatomical shapes further enhances their utility in these critical fields.

Near-Net Shape Production of Titanium Parts

Metal Injection Molding (MIM) excels at producing titanium components very close to their final desired shape. This capability, known as near-net shape production, offers significant advantages. It streamlines the manufacturing process. It also contributes to overall efficiency and cost savings.

Minimizing Post-Processing Requirements

Near-net shape production significantly reduces the need for extensive post-processing operations. Traditional manufacturing methods, such as machining from billets, often require numerous steps. These steps include cutting, grinding, and polishing to achieve the final part geometry. MIM titanium parts emerge from the sintering furnace with high dimensional accuracy. This means they require minimal, if any, additional machining. This reduction in secondary operations directly translates to lower manufacturing costs. It also conserves valuable resources. Manufacturers avoid the expense of specialized tooling and labor associated with complex machining. This is particularly beneficial for intricate titanium designs. The process also minimizes material waste, as it removes less material during finishing.

Reducing Lead Times in Manufacturing

The ability to produce near-net shape titanium parts directly impacts manufacturing lead times. Fewer post-processing steps mean a faster overall production cycle. Manufacturers do not need to schedule and execute multiple machining operations. This accelerates the journey from raw material to finished product. The efficiency of the MIM process, combined with reduced secondary operations, allows for quicker turnaround times. This is crucial in industries where rapid prototyping or fast market entry is essential. Companies can bring new titanium products to market more quickly. This provides a competitive edge. The streamlined process also simplifies supply chain management. It reduces the complexity of coordinating various manufacturing stages.

Applications of Titanium Metal Injection Molded Parts

Titanium Metal Injection Molded components find use across diverse industries. Their unique properties make them ideal for demanding applications.

Medical and Dental Implants

Biocompatibility and Complex Anatomical Shapes

Titanium’s exceptional biocompatibility makes it a prime material for medical and dental implants. MIM Ti-64 is widely used for manufacturing titanium implants and various medical devices. Rigorous biocompatibility tests for MIM Ti-64 consistently pass. These tests include hemocompatibility, cytotoxicity, sensitization, irritation, systemic toxicity, and implantation. Furthermore, a Ti-6Al-4V-0.5B alloy produced by MIM meets the stringent requirements for permanent implant materials, even with its boron content. This capability allows manufacturers to create complex anatomical shapes precisely.

Surgical Instruments and Prosthetics

MIM technology also produces intricate surgical instruments and custom prosthetics. The process allows for the creation of complex geometries with fine details. This is crucial for instruments requiring specific functionalities or for prosthetics needing a precise fit.

Aerospace Components

Lightweight, High-Strength Structural Parts

The aerospace industry heavily relies on titanium for its high strength-to-weight ratio. Titanium MIM is particularly beneficial for small, complex aerospace elements. It produces intricate geometries with superior fatigue resistance. Specific components include couplings, hinges, connectors, locks, control levers, and fasteners. For structural elements like brackets, bulkheads, and housing shells, titanium alloys offer high strength, low density, and fatigue resistance. These properties make them ideal for critical load-bearing applications. MIM ensures tight tolerances, design flexibility, superior density, and microstructure uniformity for these parts.

Engine Components and Fasteners

Titanium MIM also produces various engine components and specialized fasteners. These parts benefit from titanium’s ability to withstand high temperatures and corrosive environments. The precision of MIM ensures reliable performance in critical aerospace systems.

Automotive Parts

Performance-Critical and Weight-Reduction Components

The automotive sector increasingly adopts titanium MIM for performance-critical and weight-reduction components. Titanium’s light weight helps improve fuel efficiency and overall vehicle performance. Its strength ensures durability in demanding automotive environments.

Specialized Engine and Transmission Parts

MIM titanium finds application in specialized engine and transmission parts. These components often require complex shapes and high wear resistance. The precision and material properties offered by MIM titanium meet these stringent requirements, contributing to enhanced vehicle reliability and longevity.

Consumer Electronics

Miniaturization and Durability for Devices

The consumer electronics industry constantly seeks materials that enable miniaturization and enhance durability. Titanium Metal Injection Molded (MIM) parts offer significant advantages in this sector. Titanium’s high strength-to-weight ratio allows manufacturers to create smaller, lighter components without sacrificing structural integrity. This is crucial for portable devices where space and weight are premium considerations. Furthermore, titanium’s inherent corrosion resistance protects electronic components from environmental degradation, extending device lifespan. MIM technology precisely forms intricate titanium parts, meeting the demanding specifications of modern electronics.

Housings and Internal Components

MIM titanium finds application in various parts of consumer electronic devices. Manufacturers use it for robust device housings that protect sensitive internal components from impact and wear. Its ability to form complex shapes makes it ideal for intricate internal components, such as connectors, brackets, and camera modules. These parts often require precise dimensions and high mechanical strength. MIM titanium ensures these components perform reliably under daily use. The process also allows for aesthetic finishes, contributing to the premium look and feel of high-end electronic products.

Luxury Goods

Aesthetics and Unique Properties for High-End Products

The luxury goods market values unique materials that offer both aesthetic appeal and superior performance. Titanium MIM provides an excellent solution for high-end products. Titanium’s distinctive luster, lightweight feel, and hypoallergenic properties make it a desirable material. It offers a premium tactile experience that consumers associate with luxury. The ability to produce intricate designs with high precision further enhances its appeal in this sector. Manufacturers can create complex, visually striking components that stand out.

Watch Components and Jewelry

Titanium MIM is increasingly popular for watch components and jewelry. Watchmakers utilize MIM titanium to produce lightweight yet durable cases, bezels, and internal movement parts. The precision of MIM allows for the creation of intricate gears and complex case designs. This contributes to both the functionality and aesthetics of luxury timepieces. In jewelry, titanium’s hypoallergenic nature makes it suitable for individuals with metal sensitivities. Jewelers can craft unique, intricate designs that are both strong and comfortable to wear. MIM technology enables the production of complex jewelry pieces with fine details, offering designers greater creative freedom.

The Future of Titanium Metal Injection Molded Technology

The future of Titanium Metal Injection Molded (MIM) technology appears promising. Continuous innovation drives its expansion into new applications and markets. Researchers and manufacturers actively pursue advancements in materials and processes. This ensures the technology meets evolving industry demands.

Advancements in Materials and Processes

New Titanium Alloys for MIM

The development of new titanium alloys significantly expands MIM applications. Manufacturers optimize high-performance alloys for enhanced strength, corrosion resistance, and thermal stability. Praxis Technology, for example, actively develops a variety of titanium materials for metal injection molding. These include high-strength alloys and commercially pure materials. Their development efforts extend beyond Grade 5 (Ti-6Al-4V) to encompass a broader range of titanium-based alloys. This allows for tailored properties to suit specific industrial needs. Furthermore, the integration of hybrid 3D printing with MIM promises the manufacturing of even more complex parts.

Enhanced Sintering Technologies

Sintering techniques continue to evolve. Advances in high vacuum systems and the use of controlled, extremely pure atmospheres minimize titanium oxidation during sintering. This ensures the integrity and performance of the final components. The integration of Artificial Intelligence (AI) and the Internet of Things (IoT) also revolutionizes process monitoring. These technologies enable improved quality control and predictive maintenance. Automation in feedstock handling, debinding, and sintering processes further enhances efficiency and consistency. Additionally, the development of sustainable, recyclable feedstocks and eco-friendly binders addresses environmental concerns.

Growing Market Demand and New Applications

Expansion into Emerging Industries

The global Titanium Metal Injection Molding market shows robust growth. Projections indicate it will reach USD 2.6 billion by 2032, growing at a compound annual growth rate (CAGR) of 8.6%. Emerging markets, particularly in Asia Pacific, offer substantial opportunities for this growth. Rapid industrialization and technological advancements drive this expansion. Asia Pacific is poised to be the fastest-growing region in the titanium MIM market. Countries like China, Japan, and South Korea lead this regional growth. Consumer electronics is an emerging application area for titanium MIM. The need for miniaturization and enhanced functionality in devices like smartphones and wearable technology fuels this demand.

Increased Adoption in Existing Sectors

Existing sectors also show increased adoption of MIM titanium parts. The automotive and electronics sectors, for instance, drive demand in regions like Asia Pacific. Industries recognize the benefits of MIM titanium, such as its high strength-to-weight ratio and corrosion resistance. This leads to its greater use in aerospace, medical, and luxury goods. Manufacturers continue to find new ways to leverage MIM titanium’s unique properties. This ensures its continued relevance and growth across various established industries.

Comparing Titanium MIM to Traditional Manufacturing

Cost Savings and Efficiency

Up to 20-50% Cost Reduction Compared to Machining

Titanium Metal Injection Molding (MIM) offers significant cost advantages over traditional manufacturing methods, particularly for complex parts. Companies often achieve a 20-50% cost reduction compared to machining. This saving comes from the MIM process’s ability to produce near-net-shape components. This minimizes the need for extensive post-processing. For intricate designs, where machining would involve multiple steps and specialized tools, MIM streamlines production.

Reduced Material Waste and Production Steps

MIM significantly reduces material waste. Traditional methods, like machining from a solid block, generate substantial scrap, especially with expensive materials such as titanium. MIM uses almost all the raw material. This efficiency leads to lower material costs. The process also integrates multiple production steps into one. This eliminates the need for assembly, welding, or brazing of several smaller components. This consolidation simplifies the manufacturing workflow and lowers labor costs.

Density and Performance

Achieving 95-99.5% Density in MIM Titanium Parts

MIM titanium parts achieve high density, which is crucial for performance. After sintering, these components can reach a final density exceeding 97% of theoretical density. This high density contributes to the part’s strength and structural integrity. Manufacturers carefully control the sintering process to maximize densification.

Comparison of MIM Titanium Strength to Wrought Titanium

MIM titanium parts exhibit properties comparable to wrought titanium. This means they offer similar strength and performance characteristics. While some mechanical properties, like fatigue performance, might show slight differences, advancements in MIM technology continue to close this gap. Post-processing techniques, such as Hot Isostatic Pressing (HIP), further enhance the density and mechanical properties of MIM titanium, bringing them even closer to wrought material standards.

Process Limitations and Advantages

Suitability for Specific Part Sizes and Complexities

Titanium MIM excels in producing small, complex components. Most MIM parts, including those made with titanium, typically range from 2 grams to 100 grams. The process is highly suitable for very tiny parts, some weighing less than 20 milligrams. Other manufacturing methods struggle to produce these repeatably. MIM is well-suited for intricate designs that would be difficult or impossible to machine. These include undercuts, thin walls (down to 0.5mm), logos, and internal features. It creates intricate designs with better feature resolution than investment casting or additive manufacturing.

When to Choose MIM Over Other Methods

Manufacturers choose MIM when parts require high complexity, tight tolerances, and high volume production. MIM can hold tolerances of ±0.3% (minimum of ±0.075mm/0.003″). This makes it excellent for precise applications. The process achieves very tight tolerances, specifically within 0.1-0.3%. This is crucial for applications requiring precise fits, such as hermetic seals. The final product is dense and pore-free, contributing to its ability to form hermetic seals. For simple, large parts, or very low production volumes, other methods might be more cost-effective. However, for small, complex titanium components produced in mass quantities, MIM offers unparalleled advantages.

Metal Injection Molding (MIM) for titanium is a viable and increasingly important manufacturing process. It offers significant advantages for producing complex, high-performance titanium components despite its inherent challenges. Continued innovation expands its potential across various industries. This makes it a key technology for the future. Manufacturers leverage this process for demanding applications.

FAQ

What is Titanium Metal Injection Molding (MIM)?

Titanium MIM combines powdered metallurgy with plastic injection molding. It creates complex titanium parts. Manufacturers mix fine titanium powder with a binder. They inject this mixture into a mold. After debinding and sintering, a dense titanium component results.

Why is Titanium MIM challenging to implement?

Titanium MIM faces challenges due to titanium’s high melting point and reactivity. Titanium powder also has specific characteristics. Material costs are higher. These factors demand precise process control and specialized equipment.

What are the main benefits of using Titanium MIM?

Titanium MIM offers cost-effectiveness for complex geometries. It provides significant design freedom. Parts exhibit excellent material properties like high strength-to-weight ratio and corrosion resistance. It also enables near-net shape production.

Which industries commonly use Titanium MIM parts?

Industries like medical, dental, aerospace, automotive, and consumer electronics use Titanium MIM parts. Luxury goods also benefit from its unique properties. Its biocompatibility and strength make it versatile.

How does MIM titanium compare to traditionally manufactured titanium?

MIM titanium parts achieve properties comparable to wrought titanium. They reach 95-99.5% density. While fatigue performance may differ slightly, post-processing like Hot Isostatic Pressing (HIP) can close this gap.

Does Titanium MIM reduce manufacturing costs?

Yes, Titanium MIM can reduce costs by 20-50% compared to machining. It minimizes material waste. The process also integrates multiple production steps. This makes it economical for mass production of complex parts.

Can Titanium MIM produce parts for medical implants?

Yes, Titanium MIM is highly suitable for medical implants. Titanium’s biocompatibility is excellent. The process creates complex anatomical shapes precisely. MIM Ti-64 consistently passes rigorous biocompatibility tests.