3D Printed Titanium offers exciting possibilities. It can replace carbon fiber in specific applications, but this replacement is not universal. The decision always hinges on application-specific requirements and performance metrics. Both materials offer distinct advantages. This leads to complementary rather than purely substitutive roles in various industries. Engineers carefully evaluate each material’s strengths for optimal design.

Key Takeaways

- 3D printed titanium and carbon fiber are different materials. They each have good points for different jobs.

- 3D printed titanium is strong and light. It works well in hot places and for medical parts.

- Carbon fiber is very light and stiff. It helps make planes and cars lighter and faster.

- Engineers choose materials based on what a project needs. They look at strength, weight, and cost.

- Making things with 3D printed titanium allows for complex shapes. It can combine many parts into one.

- Making carbon fiber parts can be slow and costly. New ways of making them are helping with this.

- Sometimes, engineers use both materials together. This combines their best features for better results.

Understanding 3D Printed Titanium and Carbon Fiber

Engineers often evaluate materials based on their fundamental properties and manufacturing methods. A clear understanding of 3D printed titanium and carbon fiber is essential for making informed material selection decisions.

What is 3D Printed Titanium?

3D printed titanium refers to components fabricated using additive manufacturing techniques. These processes build parts layer by layer from titanium powder or wire.

Additive Manufacturing Processes for Titanium

Several additive manufacturing processes create titanium components. Each method offers unique advantages for specific applications. The table below outlines common techniques:

| Method | Various Technology | Fabricated Components |

|---|---|---|

| Directed Energy Deposition | Laser engineered net shaping, Electron beam direct melting, Rapid plasma deposition, Direct light fabrication, 3D laser cladding | Metals, Polymers, Composites |

| Binder Jetting | Ink jetting, 3D printing, Color jet printing | Metals, Ceramics |

| Powder Bed Fusion | Selective laser melting, Direct metal laser sintering, Selective laser sintering | Metals, Ceramics, Glass, Plastic |

| Sheet Lamination | Ultrasonic AM, Laminated object manufacturing | Metals, Ceramics |

Powder Bed Fusion, particularly Selective Laser Melting (SLM) and Electron Beam Melting (EBM), are popular for titanium. These methods precisely melt and fuse titanium powder, creating complex geometries.

Key Material Characteristics of 3D Printed Titanium

3D printed titanium exhibits several desirable material characteristics. It offers high corrosion resistance due to a protective oxide layer. This material also provides an excellent strength-to-weight ratio, delivering stability comparable to stainless steel but with less mass. Furthermore, 3D printed titanium shows good biocompatibility, making it suitable for medical applications like implants. It also possesses low thermal expansion, which is beneficial in environments with temperature fluctuations.

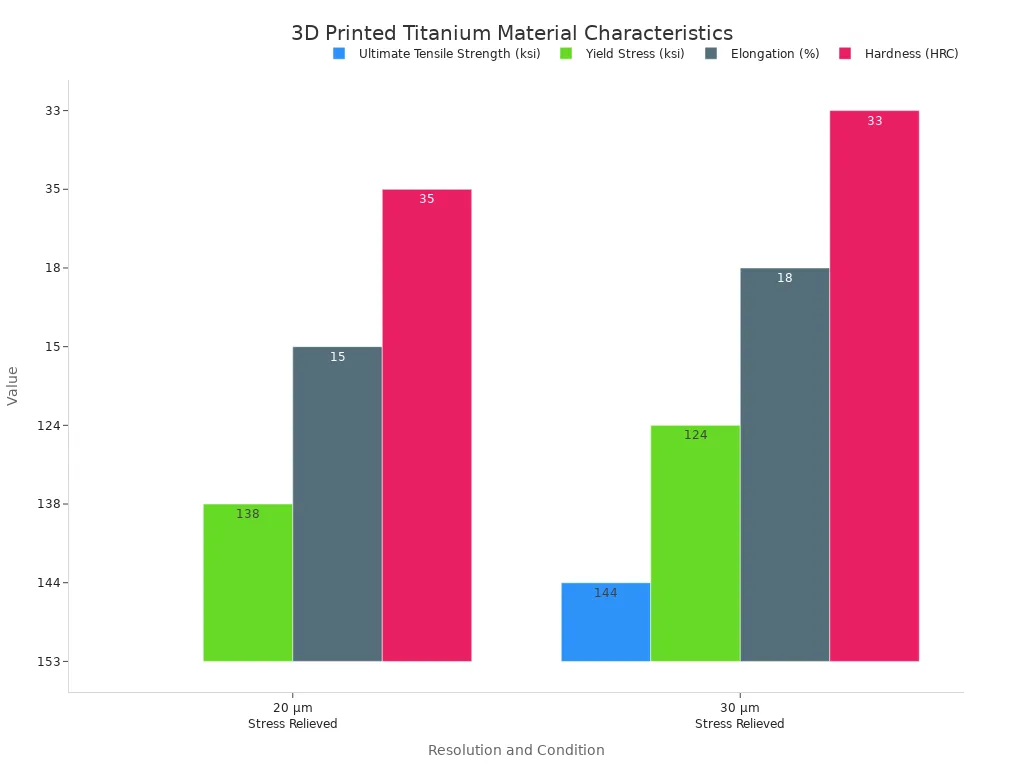

| Resolution | Condition | Ultimate Tensile Strength (MPa) | Yield Stress (MPa) | Elongation (%) | Hardness (HRC) |

|---|---|---|---|---|---|

| 20 µm | Stress Relieved | 1055 | 951 | 15 | 35 |

| 30 µm | Stress Relieved | 993 | 855 | 18 | 33 |

These properties highlight its robust mechanical performance under various conditions.

What is Carbon Fiber?

Carbon fiber is a high-performance composite material. It combines strong carbon fibers with a resin matrix.

Composite Structure and Manufacturing

Carbon fiber composites consist of reinforcement (carbon fibers) and a matrix (resin). The carbon fibers carry most of the load. They significantly contribute to the material’s overall properties. Each fiber contains thousands of filaments, very thin in diameter. The resin transfers load between fibers, prevents buckling, and binds the materials together. Carbon fiber composites are anisotropic. This means their properties, such as stiffness, depend on the fiber orientation. Manufacturers can tailor strength in specific directions by arranging multiple fabric layers at different angles.

The production of carbon fiber involves chemical and mechanical processes. It begins with drawing long fibers. These fibers then undergo very high temperatures in an oxygen-free environment to prevent burning. This heating process, called carbonization, removes most non-carbon atoms. Further heating in proprietary atmospheres converts the fibers into carbides, enhancing conductivity and strength.

Several methods exist for manufacturing carbon fiber composites:

- Manual Laminating: Workers manually apply resin with a roller and brush. This method suits simple designs.

- Vacuum Bagging: After manual resin application, a vacuum bag seals the mold. A vacuum pump extracts air, ensuring fabric adhesion and pressure.

- Resin Infusion: Dry fabrics are placed in a mold, then sealed with film. A vacuum pump removes air. Resin is then automatically supplied through netting and ducts, impregnating the dry fabrics. This method is common for medium to large composites.

- Filament Winding: Carbon fibers wind around a rotating mandrel. This method is ideal for structural components with smooth curved surfaces.

Key Material Characteristics of Carbon Fiber

Carbon fiber is extremely stiff, strong, and light. It is significantly lighter than steel or aluminum, yet up to five times stronger. Its stiffness, measured by the modulus of elasticity, is typically around 33 msi (228 GPa). Carbon fiber does not permanently deform below its ultimate tensile strength, effectively having no yield strength.

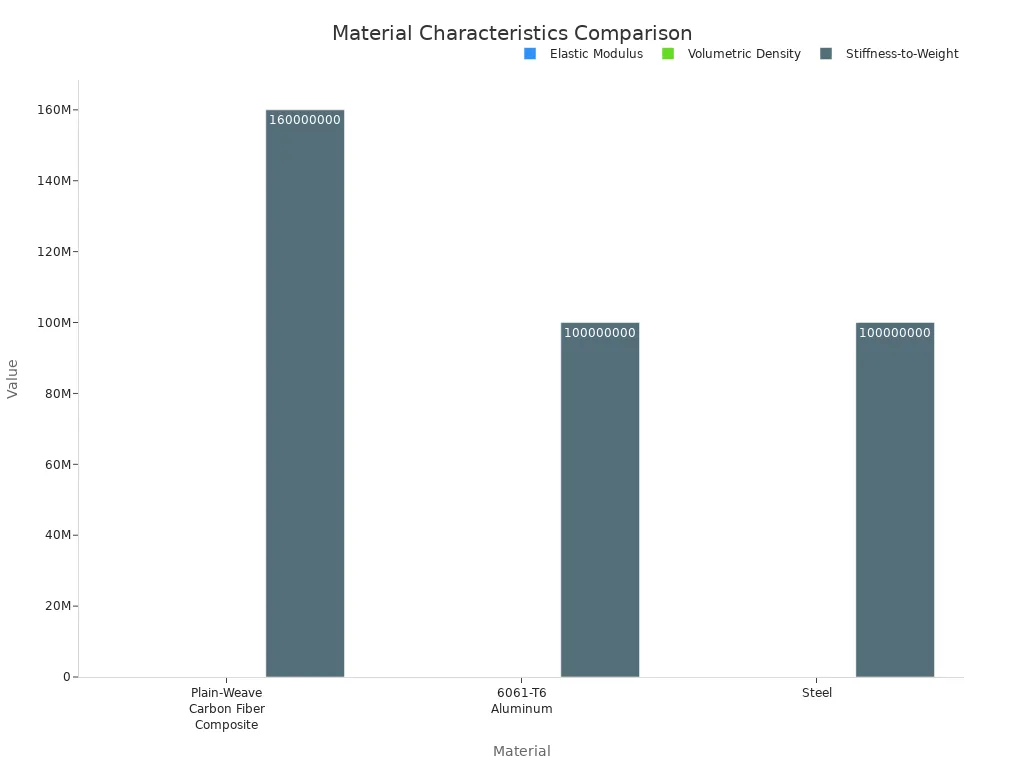

| Material | Elastic Modulus | Volumetric Density | Stiffness-to-Weight |

|---|---|---|---|

| Plain-Weave Carbon Fiber Composite | 8 msi | 0.05 lbs./in³ | 160 x 10⁶ |

| 6061-T6 Aluminum | 10 msi | 0.10 lbs./in³ | 100 x 10⁶ |

| Steel | 30 msi | 0.30 lbs./in³ | 100 x 10⁶ |

This table shows a basic plain-weave carbon fiber panel has a stiffness-to-weight ratio 60% greater than aluminum or steel. Carbon fiber also resists corrosion, tolerates heat, and exhibits good fatigue resistance. It can conduct electricity in some forms.

Direct Comparison: Performance Metrics

Engineers meticulously compare materials based on their performance metrics. This section examines how 3D printed titanium and carbon fiber stack up in critical areas.

Strength-to-Weight Ratio

The strength-to-weight ratio is a crucial metric for many advanced applications. It determines how much load a material can bear relative to its mass.

Tensile Strength of 3D Printed Titanium

3D printed titanium alloys demonstrate impressive tensile strength. These materials can achieve tensile strengths exceeding 1600 megapascals, making them among the strongest 3D-printed metals available. For common 3D printed titanium alloys like Ti6Al4V, tensile strengths often surpass 900 MPa. This high strength allows for robust designs with reduced material usage.

Carbon Fiber’s Lightweight Advantage

Carbon fiber excels in lightweight applications. Its inherent low density combined with high tensile strength results in an exceptional strength-to-weight ratio. This characteristic makes carbon fiber a preferred material for components where mass reduction is paramount, such as in aerospace and high-performance automotive industries.

Stiffness and Rigidity

Stiffness, or resistance to deformation, is another vital performance indicator.

Modulus of Elasticity in 3D Printed Titanium

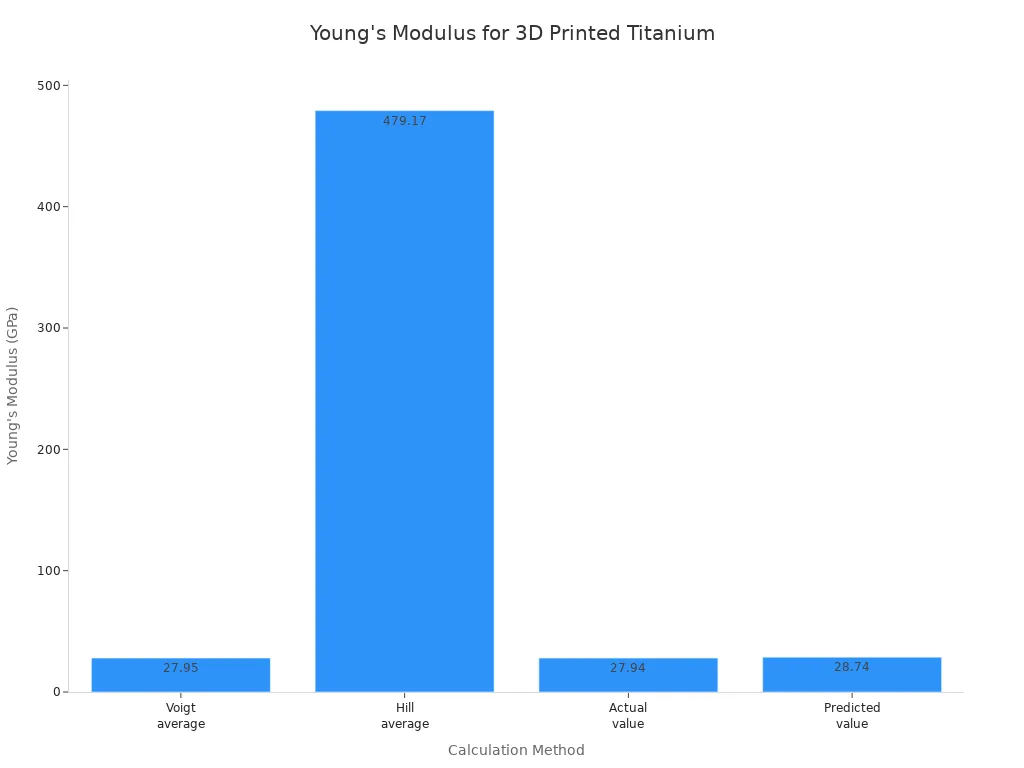

3D printed titanium exhibits a range of elastic moduli depending on the specific alloy and printing parameters. For instance, a 3D-printed β-Ti21S alloy shows an extremely low Young’s modulus of 52 ± 0.3 GPa. However, titanium generally possesses a high Young’s modulus, reaching nearly 500 GPa, which indicates excellent rigidity. The table below illustrates various calculated Young’s Modulus values for 3D printed titanium:

| Calculation Method | Young’s Modulus (GPa) |

|---|---|

| Voigt average | 27.95 |

| Hill average | 479.17 |

| Actual value | 27.94 |

| Predicted value | 28.74 |

Anisotropic Stiffness of Carbon Fiber

Carbon fiber composites are anisotropic. This means their stiffness varies significantly depending on the direction of the applied force relative to the fiber orientation. Manufacturers can strategically align fibers to achieve maximum stiffness in specific load-bearing directions, optimizing structural performance.

Durability and Fatigue Resistance

Durability and fatigue resistance are critical for long-term performance and safety.

Impact Resistance of Carbon Fiber

Carbon fiber prepreg composites show significant strain rate effects under Hopkinson impact conditions. The material exhibits more pronounced brittle failure characteristics under dynamic loading compared to quasi-static compression. Damage strength increases, failure strain decreases, and elastic modulus increases during dynamic impact. Failure modes include matrix cracking, fiber pull-out/breakage, and critical delamination. Toughening mechanisms, such as interleaving with ultra-thin layers of CNTs or aramid pulp, can significantly improve impact resistance.

Corrosion Resistance of 3D Printed Titanium

Titanium alloys generally offer excellent corrosion resistance due to a stable passive oxide layer. However, specific environments can affect this property. For example, titanium alloys can corrode in biological mediums after implantation, influenced by factors like acidic conditions, masticatory forces, and fluoride content. Pitting corrosion on commercially pure titanium can result from fluoride ion activity. Manufacturing methods also play a role; LPBF-manufactured Ti-6Al-4V often shows better corrosion performance in Ringer’s solution compared to EBM-manufactured versions.

| Environment | Manufacturing Method | Corrosion Resistance | Notes |

|---|---|---|---|

| Air (600 °C) | 3D-printed Ti-6Al-4V | Higher weight gain, more serious corrosion | Due to α’ phase formation |

| Air (600 °C) | Cold-rolled Ti-6Al-4V | Lower weight gain | |

| Air-SO2 (600 °C) | 3D-printed Ti-6Al-4V | Much higher weight gain, more serious corrosion | Sulfur species cause significant attack; due to α’ phase formation |

| Air-SO2 (600 °C) | Cold-rolled Ti-6Al-4V | Much lower weight gain |

Manufacturing and Cost Implications

Manufacturing processes and associated costs significantly influence material selection. Engineers must consider both the complexity of production and the scalability of each material.

Manufacturing Complexity and Scalability

The methods used to produce components from 3D printed titanium and carbon fiber differ greatly, impacting their overall scalability.

Production Speed for 3D Printed Titanium

Additive manufacturing offers varying production speeds for titanium components. KITECH’s refined Selective Laser Melting (SLM) process has significantly increased titanium layering speed. It now reaches up to 37.966 cm³/h, more than doubling the previous rate of 18 cm³/h. This improvement enhances the efficiency of 3D printed titanium production. Different processes also yield varying deposition rates and build times for titanium alloys.

| Material | Deposition Rate | Build Time |

|---|---|---|

| Titanium Ti64 | 6 lbs./h | 3 hours |

| Titanium Ti64 | 6 lbs./h | 1 hour |

| Titanium Ti64 | 7 lbs./h | 6 hours |

Carbon Fiber Layup and Curing Processes

Carbon Fiber Reinforced Polymers (CFRP) involve complex and often slow manufacturing processes. Processing speeds for CFRP in automated assembly remain significantly lower than traditional materials like metals and plastics. This creates a bottleneck in high-volume manufacturing. Typical processing cycles for aerospace-grade CFRP parts range from 2-8 hours. This represents a substantial productivity gap compared to the minutes required for comparable metal components. Material preparation, specifically cutting and layup of carbon fiber prepregs, remains labor-intensive with limited automation. Automated cutting systems achieve speeds of only 0.5-1.5 m/s, considerably slower than metal processing equipment. Conventional autoclave curing, a major bottleneck, requires lengthy cycle times of 2-6 hours under controlled pressure and temperature conditions. Quality control and inspection processes, such as ultrasonic scanning, operate at speeds of only 0.1-0.3 m²/min, creating inspection bottlenecks. Energy consumption for CFRP processing is typically 2-5 times higher per kilogram than conventional materials, primarily due to high-temperature curing cycles. Tooling limitations include significantly longer tool change operations and setup times. Typical changeover times for CFRP manufacturing are 2-4 hours, compared to 15-30 minutes for metal stamping operations.

Design Freedom and Customization

Each material offers distinct levels of design freedom, influencing the complexity of achievable geometries.

Geometric Complexity with 3D Printed Titanium

3D metal printing, particularly with titanium, enables the fabrication of net-shape metallic components with complex geometric shapes. This represents a key strength over traditional manufacturing methods. Internal latticework for weight reduction, difficult or impossible with traditional subtractive methods, is a specific geometric complexity achievable with 3D printed titanium.

Carbon Fiber Design Limitations

Carbon fiber manufacturing presents several design limitations. The production of carbon fiber composites is inherently complex, involving numerous steps and requiring precise control. This complexity makes the process expensive and challenging to scale. It demands specialized knowledge, skilled labor, and advanced equipment, hindering widespread adoption. Recycling carbon fiber composites also presents a significant challenge. They are thermoset materials, meaning they cannot melt down like metals or plastics. This makes proper disposal difficult and limits their role in a sustainable, circular economy. Current recycling methods are often expensive and not very effective. Stress concentration at corners is another significant design limitation. A smaller corner radius can drastically reduce the ultimate strength of the carbon fiber structure. Conversely, increasing the corner radius can enhance strength by reducing radial stress. Shrinkage during the molding process also poses a challenge. Carbon fibers themselves have a negative coefficient of thermal expansion. While some shrinkage can aid in mold removal, excessive shrinkage can lead to molding defects like warpage and shrink marks.

Cost Analysis

Material and manufacturing costs are critical factors in the economic viability of a product.

Material Costs for 3D Printed Titanium

Titanium powder for 3D printing generally costs between $300.00 and $363.00 per kilogram. For Selective Laser Melting (SLM) 3D printing, titanium alloy powders like Ti-6Al-4V typically cost between $300 and $600 per kilogram. The price varies significantly based on the specific alloy and purity.

| Alloy | Price Range per Kg |

|---|---|

| CP Ti Gr 2 | $50 – $150 |

| Ti-6Al-4V | $80 – $450 |

| Ti-6Al-4V ELI | $100 – $650 |

| Ti 6Al-7Nb | $250 – $1000 |

| Ti-555 | $150 – $850 |

| Ti-1023 | $500 – $2000 |

Carbon Fiber Manufacturing Costs

Carbon fiber manufacturing costs are influenced by the complex, multi-step production process. The labor-intensive nature of layup, the long curing cycles, and the specialized equipment required contribute to higher overall production expenses compared to many traditional materials. The energy consumption for CFRP processing also adds to the cost. These factors often make carbon fiber components more expensive for mass production, despite the material’s performance benefits.

Advantages of 3D Printed Titanium

3D Printed Titanium offers significant benefits across various industries. Its unique properties and manufacturing flexibility make it a preferred choice for demanding applications.

High-Temperature Performance

Titanium’s inherent properties make it suitable for environments with elevated temperatures. This material maintains its structural integrity even under extreme heat.

Thermal Stability of 3D Printed Titanium

Titanium alloys exhibit excellent thermal stability. They retain their strength and shape at high temperatures. Pure titanium, for example, shows good stability up to 400°C (750°F). Its high melting point of 1668°C (3034°F) contributes to this capability. Different titanium alloys offer varying levels of thermal performance, tailored for specific needs.

| Material Type | Thermal Stability / Creep Resistance | Notes |

|---|---|---|

| Pure Titanium (Grade 1-4) | Good thermal stability up to 400°C (750°F) | Excellent corrosion resistance, good strength-to-weight ratio, low density, high melting point (1668°C / 3034°F). |

| Alpha Alloys (e.g., Ti-5Al-2.5Sn) | Good creep resistance at elevated temperatures (up to 500°C / 930°F) | Enhanced high-temperature strength and creep resistance compared to pure titanium. |

| Near-Alpha Alloys (e.g., Ti-6Al-2Sn-4Zr-2Mo) | Excellent creep resistance at higher temperatures (up to 600°C / 1110°F) | Developed for aerospace applications requiring superior high-temperature performance. |

| Alpha-Beta Alloys (e.g., Ti-6Al-4V) | Good thermal stability and creep resistance up to 350°C (660°F) | Most common titanium alloy, offering a balance of strength, ductility, and thermal properties. |

| Beta Alloys (e.g., Ti-10V-2Fe-3Al) | Good thermal stability, but generally lower creep resistance than alpha or near-alpha alloys at very high temperatures | High strength, good hardenability, and excellent formability. Often used in applications requiring high strength at moderate temperatures. |

| Titanium Aluminides (e.g., TiAl) | Excellent high-temperature strength and creep resistance (up to 800°C / 1470°F) | Intermetallic compounds with superior high-temperature properties, but can be brittle at room temperature. Used in advanced aerospace and automotive applications. |

| Titanium Matrix Composites (TMCs) | Enhanced thermal stability and creep resistance, depending on reinforcement material (e.g., SiC fibers) | Offer improved high-temperature performance and stiffness compared to conventional titanium alloys. |

| General Titanium Properties | High melting point (1668°C / 3034°F), low thermal expansion, low thermal conductivity | These properties contribute to titanium’s ability to maintain strength and structural integrity at elevated temperatures, making it suitable for high-performance applications. |

Creep Resistance in High Heat

Creep refers to a material’s tendency to deform permanently under mechanical stress at elevated temperatures. Titanium alloys, especially alpha and near-alpha types, demonstrate excellent creep resistance. This property ensures components maintain their shape and function over long periods in hot environments. For example, near-alpha alloys like Ti-6Al-2Sn-4Zr-2Mo offer superior creep resistance up to 600°C (1110°F), making them ideal for aerospace engine parts.

Biocompatibility and Medical Applications

Titanium’s compatibility with the human body makes it invaluable for medical devices. Its unique properties support integration with biological tissues.

Osseointegration Properties of 3D Printed Titanium

3D printing technology significantly enhances the biocompatibility and osseointegration of porous titanium alloys. Osseointegration describes the direct structural and functional connection between living bone and the surface of a load-bearing implant.

- Increased surface roughness of 3D-printed titanium implants (SLM) significantly enhances osseointegration strength compared to conventional implants (CNC-SLA).

- Microscale bone interlocking is observed on SLM implants after week 2, facilitating better engagement with bone tissue.

- SLM implants demonstrated significantly greater removal torque at week 2 compared to CNC-SLA implants at the same time point, and comparable to CNC-SLA implants at week 8.

- Microscale finite element analysis showed that the rough surface of SLM implants disperses harmful strains at the bone-implant interface into the surrounding bone, reducing damage risk.

- 3D-printed titanium implants have shown accelerated osseointegration, with increased bone-to-implant contact after 8 weeks in human jaws and superior osseointegration strength in animal experiments. This technology allows for personalized customization and precise control of micro-organization and structural design, which contributes to improved osseointegration.

Custom Prosthetics and Implants

The ability to create complex, patient-specific geometries makes 3D printing ideal for medical applications. Surgeons use 3D printed titanium to produce custom prosthetics, dental implants, and orthopedic devices. This customization ensures a perfect fit and improved patient outcomes. The technology also allows for porous structures that encourage bone growth into the implant, further enhancing integration.

Complex Geometries and Part Consolidation

Additive manufacturing unlocks new possibilities for design, allowing for intricate shapes and functional integration.

Lightweighting through Lattice Structures in 3D Printed Titanium

Engineers frequently use lattice structures to reduce weight while preserving mechanical strength. Titanium’s high specific strength (strength to density ratio) makes it an excellent material for lightweight designs, particularly in medical applications. For example, a long-strip space mirror, requiring strict weight and stiffness constraints, utilizes a 3D printed titanium alloy support structure. This structure incorporates an outer skin and an internal lattice. This design enhances specific stiffness and achieves significant lightweighting, addressing challenges like a small installation interface and a high center of mass.

Reducing Assembly Steps with 3D Printed Titanium

3D printing allows for the consolidation of multiple parts into a single, complex component. This process significantly reduces the number of individual parts in an assembly. Part consolidation simplifies manufacturing, lowers assembly costs, and minimizes potential points of failure. For instance, an aerospace bracket traditionally made from several machined pieces can become one integrated 3D printed titanium part.

High-Stress, Low-Volume Components

Industries requiring components that withstand extreme forces but are produced in limited quantities often find significant value in advanced manufacturing techniques. These applications prioritize performance and reliability over mass production cost.

Aerospace Brackets with 3D Printed Titanium

Aerospace manufacturers increasingly turn to 3D printed titanium for critical structural components. These parts must endure immense stress while contributing minimally to overall weight. Every new Airbus A350 XWB now incorporates 3D printed metal components, specifically titanium brackets. These brackets secure the connection between the aircraft’s wings and engines. This decision stemmed from the superior quality achievable through 3D printing, alongside economic advantages.

Airbus achieved a significant milestone by installing a 3D-printed titanium bracket on the A350 XWB’s pylon. This marked the first instance of a 3D-printed metal part used in a serial-production aircraft. This highlights the growing adoption of additive manufacturing for structural components. Airbus engineers successfully 3D printed titanium brackets, leading to significant benefits. These benefits include reduced material waste, part consolidation, optimized geometries, and lighter-weight components. This approach not only cut production costs but also contributes to fuel savings over the satellites’ lifespan due to the reduced weight.

Boeing utilizes 3D printed titanium (Ti-6AL-4V) for aft galley brackets in its 787 Dreamliner aircraft. These structural components, produced using Norsk Titanium’s Rapid Plasma Deposition (RPD) technology, are FAA-certified. Seven of these brackets are installed on each aircraft. This makes them a highly successful structural aerospace component manufactured with additive manufacturing. In spacecraft, 3D printed titanium is used for complex satellite antenna mounts and sensor brackets. This application aims to reduce weight while maintaining rigidity. This is especially crucial for components exposed to extreme temperature variations.

Motorsport Components from 3D Printed Titanium

Motorsport demands peak performance from every component. Teams constantly seek ways to reduce weight and improve structural integrity. 3D printed titanium offers a compelling solution for these high-stress, low-volume applications. Engineers can design intricate geometries, such as optimized suspension components, gearbox housings, and exhaust systems. These designs maximize strength while minimizing mass. The ability to rapidly prototype and iterate designs also provides a competitive edge. Teams can quickly test and refine parts, adapting to specific track conditions or performance requirements. This customization and rapid development cycle make 3D printed titanium invaluable in the fast-paced world of professional racing.

Advantages of Carbon Fiber

Carbon fiber offers distinct advantages across numerous industries. Its unique combination of properties makes it indispensable for applications demanding high performance.

Extreme Lightweighting for Large Structures

Carbon fiber excels at reducing weight in large-scale constructions. This capability significantly enhances efficiency and performance in various sectors.

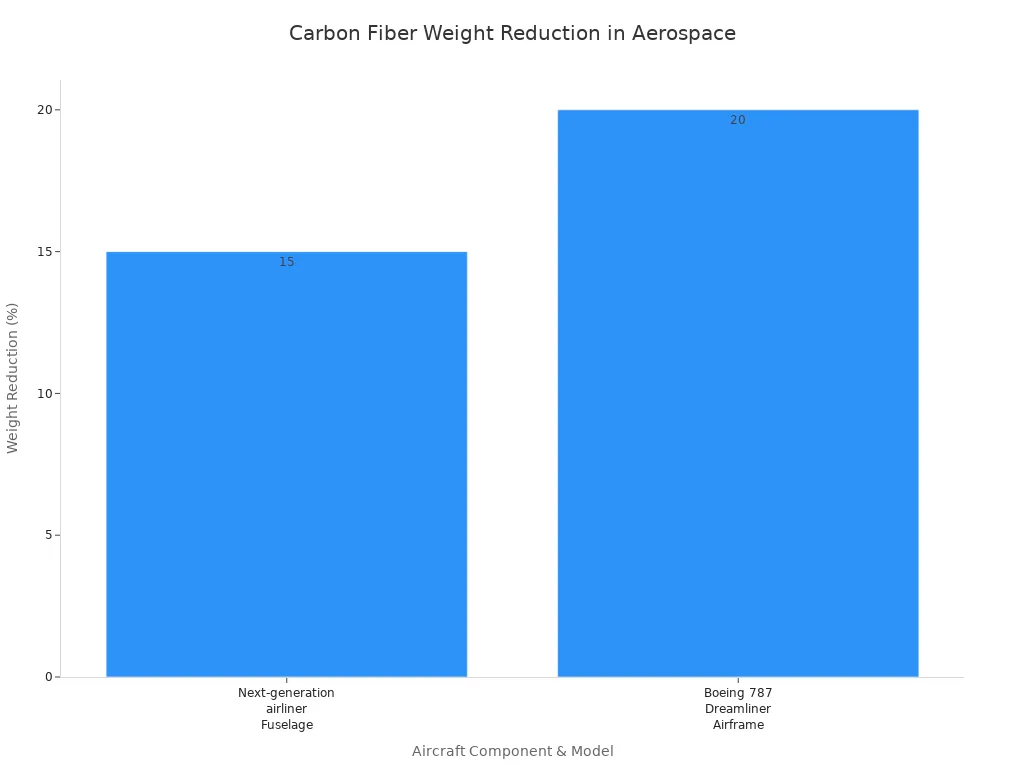

Aerospace Fuselages and Wings with Carbon Fiber

The aerospace industry heavily relies on carbon fiber for its lightweighting capabilities. Manufacturers use carbon fiber composites to construct major aircraft components. This significantly reduces the overall weight of the aircraft. For example, next-generation airliners utilize high-modulus carbon fiber aerospace materials and prepreg layup in their fuselages. This achieves a 15% weight reduction. The Boeing 787 Dreamliner airframe, including wings, fuselages, and tail assemblies, incorporates over 50% carbon fiber aerospace composites. This results in a 20% weight reduction compared to traditional aluminum designs.

| Aircraft Component | Aircraft Model/Type | Carbon Fiber Application | Weight Reduction |

|---|---|---|---|

| Fuselage | Next-generation airliner | High-modulus carbon fiber aerospace materials and prepreg layup | 15% |

| Airframe (wings, fuselages, tail assemblies) | Boeing 787 Dreamliner | Over 50% carbon fiber aerospace composites | 20% (compared to aluminum) |

This substantial weight reduction translates into improved fuel efficiency and increased payload capacity for aircraft.

High-Performance Automotive Chassis with Carbon Fiber

High-performance automotive manufacturers frequently choose carbon fiber for chassis construction. This material’s exceptional strength-to-weight ratio allows for the creation of incredibly stiff yet lightweight vehicle structures. A lighter chassis improves acceleration, handling, and braking performance. It also contributes to better fuel economy. Carbon fiber enables engineers to design complex monocoque structures. These structures integrate safety and performance features while keeping mass to a minimum. This makes carbon fiber a critical material for racing cars and luxury sports vehicles.

Superior Stiffness-to-Weight Ratio

Carbon fiber’s stiffness-to-weight ratio is a key advantage. It provides excellent rigidity without adding excessive mass. This property is crucial for applications requiring precise control and minimal deformation.

Sporting Goods Utilizing Carbon Fiber

The sporting goods industry widely adopts carbon fiber. Its superior stiffness-to-weight ratio enhances performance in various equipment. Tennis rackets, golf clubs, bicycles, and fishing rods all benefit from carbon fiber construction. A stiffer tennis racket provides more power and control. A lightweight, rigid bicycle frame transfers pedaling energy more efficiently. This allows athletes to achieve higher speeds and better results. Carbon fiber’s ability to deliver strength and stiffness at a low weight gives athletes a competitive edge.

Robotic Arms with Carbon Fiber Components

Robotic arms require high stiffness and low inertia for precise and rapid movements. Carbon fiber components meet these demands effectively. Using carbon fiber in robotic arms reduces their overall weight. This allows for faster acceleration and deceleration. The material’s high stiffness minimizes deflection and vibration during operation. This ensures greater accuracy and repeatability in tasks. Carbon fiber enables the design of longer reach robotic arms without compromising precision. This expands the operational envelope for industrial automation and specialized robotics.

Vibration Damping Properties

Carbon fiber exhibits valuable vibration damping characteristics. This property helps control unwanted oscillations and noise in various applications.

Acoustic Applications of Carbon Fiber

Carbon fiber composites play a role in acoustic applications due to their vibration damping properties. Twill weave patterns significantly influence the acoustic performance of these composites. The material’s ability to dampen vibrations directly links to its acoustic performance. Vibrations often manifest as sound waves. Incorporating a twill weave allows for the creation of carbon fiber composites. These composites not only reduce unwanted vibrations but also minimize noise generation. This is particularly beneficial in sectors like automotive and aerospace where noise reduction is critical.

While carbon fiber reinforced polymer composites possess high mechanical properties, their low viscoelastic properties can limit their effectiveness in applications requiring significant vibration damping. Repetitive high-amplitude vibrations can promote micro-crack propagation. This reduces the longevity of carbon structures. To address this, methods such as interleaving with flax and viscoelastic layers can improve the damping properties. A manufactured carbon fiber reinforced panel demonstrated improved efficiency compared to a baseline configuration. It showed almost double the modal damping and a 10 dB gain in global noise reduction.

Precision Instruments Using Carbon Fiber

Precision instruments often require materials with excellent vibration damping to maintain accuracy. Carbon fiber helps isolate sensitive components from external vibrations. This ensures stable and reliable operation. Telescopes, microscopes, and metrology equipment benefit from carbon fiber’s ability to absorb and dissipate vibrational energy. This minimizes image distortion or measurement errors. The material’s thermal stability also contributes to instrument precision. It prevents dimensional changes due to temperature fluctuations. Carbon fiber provides a stable platform for highly sensitive scientific and industrial tools.

Cost-Effectiveness in Mass Production

Carbon fiber’s journey from specialized material to broader industrial use often depends on its manufacturing cost-effectiveness, especially in large-scale production. Manufacturing processes significantly influence the final price of carbon fiber components.

Prepreg Manufacturing of Carbon Fiber

Prepreg, or pre-impregnated carbon fiber, represents a crucial material form for high-performance applications. Manufacturers impregnate carbon fiber fabrics with a resin system beforehand. This process offers several advantages for mass production.

| Feature | Prepreg Carbon Fiber |

|---|---|

| Material & Equipment Cost | Higher |

| Production Speed | Faster in mass production |

| Labor Cost | Lower due to pre-impregnation |

| Production Type | High-volume, high-performance |

The pre-impregnation reduces labor costs during component fabrication because workers do not need to mix and apply resin manually. This leads to faster production speeds in mass manufacturing environments. However, the production of carbon fiber prepreg involves sophisticated manufacturing processes. This makes it relatively expensive compared to traditional materials. These high production costs can limit its adoption, especially in cost-sensitive industries. Despite advancements, mass production of carbon fiber prepreg remains limited. Its high-end pricing and associated risks can hinder wider acceptance.

Automated Layup Processes for Carbon Fiber

Automated layup processes are vital for improving the cost-effectiveness of carbon fiber in mass production. These methods replace manual labor with robotic systems. Automated fiber placement (AFP) and automated tape laying (ATL) machines precisely position carbon fiber plies onto molds. This significantly increases production speed and consistency.

Automated systems reduce human error and ensure uniform material distribution. This leads to higher quality parts with fewer defects. The faster processing times and reduced labor requirements directly translate into lower manufacturing costs per unit. This makes carbon fiber components more economically viable for larger production volumes. Automation also allows for greater design complexity and repeatability. This further enhances the material’s appeal for industries seeking both performance and efficiency.

Emerging Trends and Hybrid Solutions

Material science constantly evolves, leading to innovative approaches in engineering. Hybrid solutions and continuous advancements in manufacturing technologies are shaping the future of material selection.

Combining 3D Printed Titanium and Carbon Fiber

Engineers increasingly explore methods to leverage the strengths of both 3D printed titanium and carbon fiber. This creates components with optimized performance characteristics.

Titanium Inserts in Carbon Fiber Structures

Designers integrate titanium inserts into carbon fiber structures to enhance specific areas. These inserts provide localized strength, wear resistance, or improved connection points. Companies are already pioneering hybrid solutions. Superstrata, for example, developed a custom unibody carbon fiber composite bicycle frame. This frame incorporates titanium, built without joints, glue, or bolts, using continuous carbon fiber composite. It boasts a strength-to-weight ratio 61 times higher than steel and weighs less than 1.3kg.

Hybrid Manufacturing Techniques

Hybrid manufacturing techniques combine the benefits of additive and traditional methods. Sturdy Cycles creates custom titanium road bikes. They combine drawn titanium tubing with 3D-printed titanium junctions, also known as lugs. They also produce custom 3D-printed titanium forks, stems, cranksets, and seat posts. Bastion Cycles utilizes 3D metal printers to create titanium lugs. These lugs connect to carbon fiber tubes. This method allows for custom geometry, optimized flex patterns, internal cable routing, and aerodynamic shapes. It leverages the strengths of both materials for superior performance and weight reduction.

Advancements in 3D Printed Titanium Technology

The field of 3D printed titanium continues to see rapid innovation. New alloys and improved processes expand its capabilities.

New Alloys and Printing Processes

Researchers are constantly pushing the boundaries of 3D printed titanium. RMIT University researchers developed a new approach. They predict the grain structure of metals in additive manufacturing. This guides the design of high-performance alloys. They found the constitutional supercooling parameter (P) most reliable for selecting alloying elements. This achieves desired grain structures, leading to stronger, more ductile, and 29% cheaper titanium alloys with uniform grain structures. Electron Beam Powder Bed Fusion (EB-PBF) offers excellent printing stability, speed, and reduced oxidation risk. This method particularly benefits industries requiring large-size and high-quality parts. Furthermore, AI and machine learning optimize titanium alloy properties. These include density, strength, and ductility. This allows for material customization for specific needs. It significantly speeds up the manufacturing process, reducing the time to understand new material responses from years to weeks.

Improved Surface Finishes for 3D Printed Titanium

Post-processing techniques are also advancing. These techniques aim to achieve smoother surface finishes for 3D printed titanium components. Improved surface quality enhances fatigue resistance and reduces the need for extensive machining.

Future of Material Selection

The future of material selection will prioritize specific application needs and continuous innovation.

Application-Driven Material Choices

Engineers will continue to make material choices based on the unique demands of each application. Performance metrics, cost, and manufacturing feasibility will guide these decisions.

Evolving Material Science and Engineering

Material science and engineering will continue to evolve. This will introduce new materials and hybrid solutions. These advancements will further blur the lines between traditional material applications. They will offer engineers more versatile tools for design and innovation.

3D printed titanium and carbon fiber fulfill distinct, often complementary roles. Engineers do not universally replace one with the other. Instead, direct replacement depends on specific application demands. Both materials will continue to evolve. This evolution will expand their utility across various industries, offering more versatile solutions. Their combined advancements promise innovative engineering possibilities.

FAQ

Can 3D printed titanium fully replace carbon fiber?

No, 3D printed titanium does not universally replace carbon fiber. Engineers choose materials based on specific application needs. Both materials offer distinct advantages, often serving complementary roles rather than purely substitutive ones.

Which material is stronger, 3D printed titanium or carbon fiber?

Both materials offer high strength. 3D printed titanium alloys can achieve over 900 MPa tensile strength. Carbon fiber excels in strength-to-weight ratio, making it very strong for its mass. The best choice depends on the specific load and application.

Which material is lighter, 3D printed titanium or carbon fiber?

Carbon fiber is generally lighter than 3D printed titanium. Its low density combined with high strength makes it ideal for extreme lightweighting applications. Titanium offers a good strength-to-weight ratio but is denser than carbon fiber.

Is 3D printed titanium good for high temperatures?

Yes, 3D printed titanium exhibits excellent thermal stability. It retains strength and shape at high temperatures, with some alloys performing well up to 600°C. This makes it suitable for hot environments like aerospace engine parts.

Does carbon fiber dampen vibrations well?

Carbon fiber composites can dampen vibrations. Engineers use specific weave patterns and hybrid approaches, like interleaving with viscoelastic layers, to enhance this property. This helps reduce noise and improve stability in precision instruments.

Which material is more cost-effective for mass production?

Carbon fiber manufacturing can be expensive due to complex processes and specialized equipment. Automated layup helps reduce costs. 3D printed titanium also has high material costs. Cost-effectiveness depends heavily on production volume and part complexity.

Can engineers combine 3D printed titanium and carbon fiber?

Yes, engineers increasingly combine these materials. They use titanium inserts in carbon fiber structures for localized strength or connection points. Hybrid manufacturing techniques, like 3D printed titanium lugs with carbon fiber tubes, leverage both materials’ strengths for optimized performance.