Titanium 3D printing offers a unique blend of benefits and challenges. Many industries, such as aerospace and healthcare, recognize the advantages of titanium due to its long-term value and lightweight strength. However, the high initial investment and complexities of the printing process can pose significant hurdles. Understanding these factors is essential for businesses considering titanium 3D printing.

Key Takeaways

- Titanium 3D printing is highly biocompatible, making it ideal for medical implants and reducing the risk of adverse reactions.

- The lightweight strength of titanium allows for strong yet light components, benefiting industries like aerospace and automotive.

- Titanium can withstand high temperatures, making it suitable for demanding applications in aerospace and automotive sectors.

- Design flexibility in titanium 3D printing enables the creation of complex geometries that traditional methods cannot achieve.

- Titanium’s corrosion resistance makes it durable in harsh environments, enhancing the longevity of components.

- High material costs and process complexity are significant barriers to the widespread adoption of titanium 3D printing.

- Production speed can be improved by optimizing printer parameters, making titanium 3D printing more competitive with traditional methods.

- Despite its challenges, titanium 3D printing offers lower material waste compared to traditional manufacturing, promoting sustainability.

Advantages of Titanium 3D Printing

Biocompatibility

Titanium 3D printing excels in biocompatibility, making it a preferred choice for medical applications. The material’s compatibility with human tissue reduces the risk of adverse reactions. Studies demonstrate that 3D-printed titanium implants exhibit favorable biocompatibility. For instance, a study titled “Biocompatibility of Bespoke 3D-Printed Titanium Alloy Plates for Treating Acetabular Fractures” utilized both in vitro and in vivo tests. The findings revealed no significant cytotoxicity compared to traditional titanium alloy plates.

| Study Title | Methodology | Findings |

|---|---|---|

| Biocompatibility of Bespoke 3D-Printed Titanium Alloy Plates for Treating Acetabular Fractures | In vitro and in vivo tests, including intradermal and intravenous injection, and intramuscular implantation | Demonstrated favorable biocompatibility of 3D-printed titanium alloy plates with no significant cytotoxicity compared to traditional titanium alloy plates. |

Moreover, the biosafety of 3D-printed titanium implants matches that of traditionally fabricated titanium implants. Custom implants produced through 3D printing not only replace but may also surpass traditional options in terms of functionality and adaptability.

- The biosafety of 3D-printed titanium implants is comparable to that of traditionally fabricated titanium implants.

- 3D-printed custom implants have the potential to not only replace but possibly surpass traditionally fabricated titanium implants in terms of usage.

Lightweight Strength

The lightweight strength of titanium 3D printing significantly benefits various industries. Titanium’s high strength-to-weight ratio allows for the creation of components that are both strong and lightweight. This characteristic is particularly advantageous in sectors such as aerospace, automotive, and medical devices.

| Material | Tensile Strength (MPa) | Yield Strength (MPa) |

|---|---|---|

| Forged Ti-6Al-4V | 1000 | 900 |

| 3D Printed Ti-6Al-4V | 950–1000 | 850–900 |

Industries that benefit from this lightweight strength include:

| Industry | Benefits |

|---|---|

| Aerospace | High-performance materials that can withstand demanding conditions. |

| Medical Devices | Biocompatibility for custom prosthetics and surgical tools. |

| Automotive | Lightweight components that improve energy efficiency and performance. |

| Marine | Corrosion resistance for specialized parts used in harsh environments. |

Additionally, lighter components enhance performance and energy savings across various applications. In the medical field, custom prosthetics and implants tailored to individual anatomy improve patient outcomes.

High-Temperature Resistance

Titanium 3D printing also offers exceptional high-temperature resistance, making it suitable for demanding applications in aerospace and automotive industries. The material can withstand service temperatures higher than aluminum alloys, capable of enduring between 450°C to 500°C for extended periods.

| Property | Detail |

|---|---|

| Service Temperature | Higher than aluminum alloys, capable of 450°C to 500°C for extended periods. |

| Low-Temperature Performance | Retains plasticity at -253°C. |

| Corrosion Resistance | Superior to stainless steel, especially against pitting and acid corrosion. |

The high strength and low density of titanium reduce material usage while maintaining required strength. This lightweight property contributes to lower fuel costs in aerospace applications. Furthermore, titanium’s ability to produce parts with high unit strength and good rigidity makes it an ideal choice for critical components.

- High strength and low density reduce material usage for required strength.

- Lightweight properties contribute to lower fuel costs in aerospace applications.

- Suitable for producing parts with high unit strength and good rigidity.

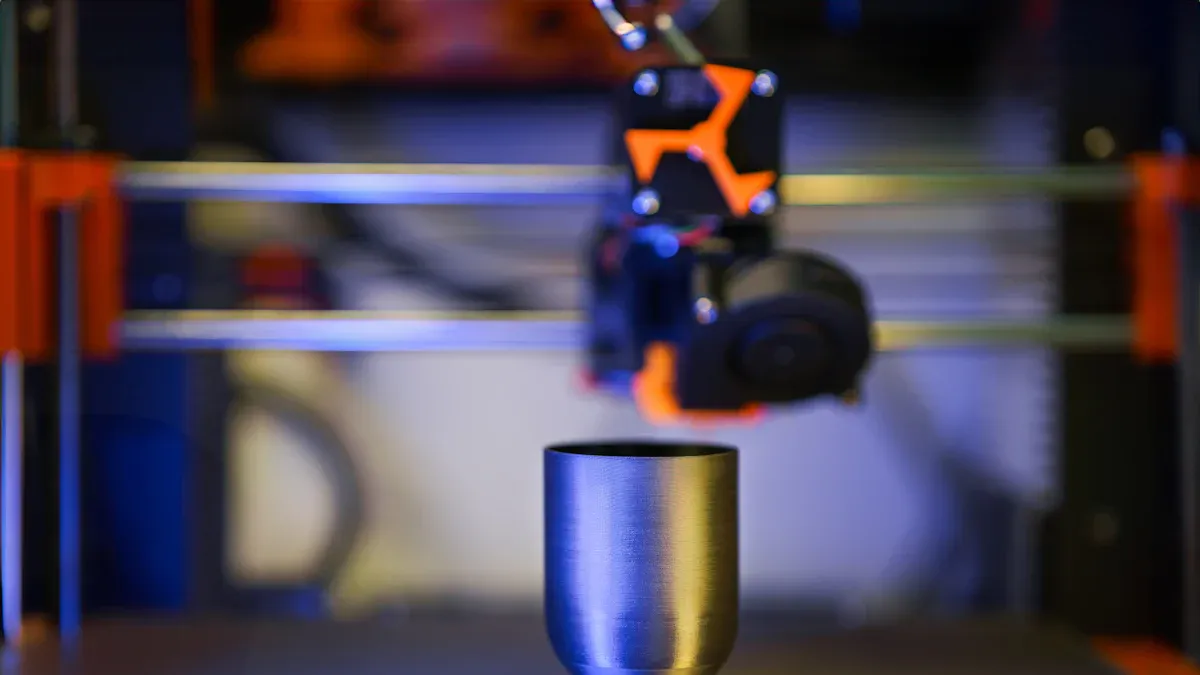

Design Flexibility

Titanium 3D printing offers remarkable design flexibility, enabling engineers to create complex geometries that traditional manufacturing methods cannot achieve. This capability is crucial in various industries, including aerospace, automotive, and healthcare. The technology allows for the production of intricate details, such as lightweight and complex geometries essential for performance in various designs. For example, turbine blades with internal cooling channels can be manufactured, enhancing efficiency and performance.

- Key Benefits of Design Flexibility:

- Creation of lightweight and complex geometries.

- Production of intricate details, such as those found in finished wheel hub mounts.

- Development of patient-specific implants and prosthetics, improving comfort and functionality.

- Minimization of material waste while producing lightweight, intricate designs.

In aerospace, intricate titanium components are lighter and more durable, contributing to overall performance. In healthcare, custom implants tailored to individual patients significantly improve surgical outcomes. The ability to produce such geometries not only enhances functionality but also fosters innovation across various sectors.

Corrosion Resistance

Corrosion resistance is another significant advantage of titanium 3D printing. Titanium alloys, particularly Ti-6Al-4V, exhibit excellent mechanical properties and superior corrosion resistance, making them suitable for harsh environments. Studies have evaluated the corrosion resistance of 3D-printed titanium alloy Ti64-ELI in Ringer’s and NaCl solutions, simulating marine and chemical environments. The findings indicate that Ringer’s solution exhibited higher corrosion rates compared to NaCl, highlighting the environmental influence on corrosion behavior.

- Corrosion Resistance Insights:

- Ti-6Al-4V alloy is extensively studied for its electrochemical behavior, especially in marine environments.

- Experimental findings show that the weight gain of 3D-printed Ti-6Al-4V was significantly higher than that of cold-rolled Ti-6Al-4V when exposed to high-temperature environments. This suggests that the corrosion resistance of 3D-printed titanium components may be inferior to that of conventionally produced titanium parts, particularly due to the detrimental effects of sulfur species in the environment.

Despite these challenges, the corrosion resistance of titanium 3D-printed components remains a compelling advantage, especially in applications where durability and longevity are critical.

Disadvantages of Titanium 3D Printing

High Cost

One of the most significant drawbacks of titanium 3D printing is its high cost. The average price of titanium powder used in 3D printing ranges from $200 to $500 per kilogram. In contrast, traditional manufacturing methods typically cost between $100 and $150 per kilogram. This stark difference in material costs can deter businesses from adopting titanium 3D printing, especially for large-scale production.

| Method | Average Cost per kg |

|---|---|

| 3D Printing (Titanium Powder) | $200-$500 |

| Traditional Manufacturing | $100-$150 |

Several factors contribute to the high costs associated with titanium 3D printing:

- High material costs

- Production efficiency

- Technological requirements

- Demand for lightweight, high-strength materials

- Innovations in additive manufacturing

- Development of cost-effective alloys and recycling techniques

Despite the potential for return on investment (ROI) through in-house prototyping, the initial investment remains a barrier. However, businesses may find cost efficiency in small and medium batch production compared to traditional methods.

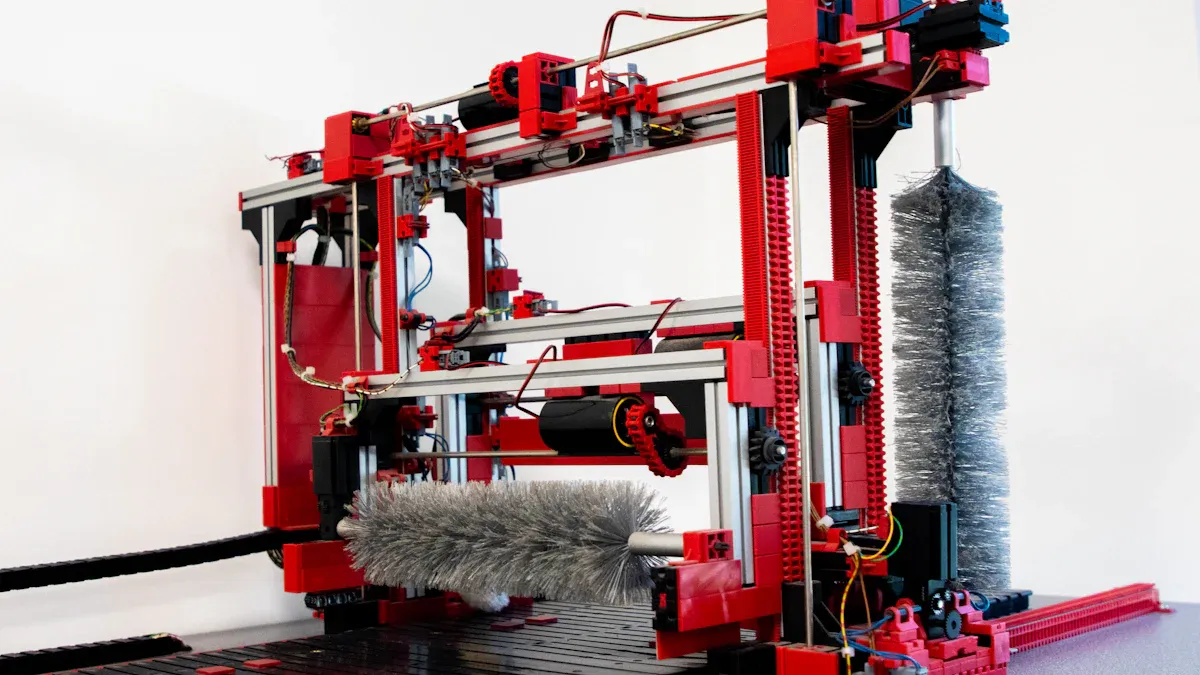

Complexity of Process

The complexity of the titanium 3D printing process presents another challenge. This technology requires skilled operators to navigate various technical hurdles. The following table outlines some of the key challenges associated with the process:

| Challenge | Description |

|---|---|

| Designing support structures | Necessary for complex geometries to ensure stability during printing. |

| Managing thermal behavior | Critical to prevent warping and ensure dimensional accuracy. |

| Optimizing powder characteristics | Important for ensuring flowability and density of the powder used in the printing process. |

| Calibrating process parameters | Essential for achieving consistent outcomes, as small changes can lead to part failures. |

| Addressing post-processing issues | Involves challenges like support removal and surface finishing to achieve desired quality. |

These complexities can lead to increased production times and costs. Additionally, issues such as striation can result in unusable products, particularly in critical applications like medicine.

Material Limitations

Titanium 3D printing also faces material limitations that restrict its broader application. Some of the key concerns include:

- High Costs: Titanium powder can cost around $450 per kilogram, which is a significant barrier to wider adoption.

- Reliability Concerns: The complexity of 3D printing titanium requires skilled operators. Issues like striation can lead to unusable products, especially in critical applications like medicine.

- Scalability Limitations: Current technology is limited to small parts, making it unsuitable for larger components, which restricts its application in various industries.

While heat treatment can enhance the mechanical properties of titanium parts, the overall reliability and scalability of 3D printed titanium components remain areas of concern.

Production Speed

Production speed in titanium 3D printing significantly influences its viability for various applications. Several factors affect how quickly manufacturers can produce parts. Key elements include:

- Filament viscosity and strength: These properties determine the material’s printability.

- Liquefier geometry: The design of the liquefier impacts the rate of printing.

- Printer parameters: Essential settings such as laser power, scan speed, hatch distance, stripe width, and stripe overlap must be optimized to enhance production speed.

- Porosity: This characteristic affects the performance of 3D-printed parts. Factors influencing porosity include powder properties and the specific printing processes used.

Optimizing these parameters can lead to significant improvements in production speed, making titanium 3D printing more competitive with traditional manufacturing methods. However, achieving the right balance between speed and quality remains a challenge for many manufacturers.

Environmental Impact

The environmental impact of titanium 3D printing is a critical consideration for industries looking to adopt this technology. The energy consumption associated with titanium 3D printing processes poses significant environmental challenges. Notably, titanium production is energy-intensive, requiring nearly ten times more energy than steel. This high energy requirement contributes to a substantial carbon footprint throughout the lifecycle of titanium, from mining to primary metal production.

In terms of waste generation, titanium 3D printing offers advantages over traditional manufacturing methods. The following table illustrates the differences in material waste between the two approaches:

| Method | Buy-to-Fly Ratio | Material Waste Percentage |

|---|---|---|

| Traditional Machining | 12:1 to 25:1 | Up to 90% |

| Titanium 3D Printing | As low as 3:1 | Significantly lower |

Titanium 3D printing minimizes waste by melting only a small amount of powder and allowing for the reuse of powder multiple times. Studies indicate that titanium powder remains viable through several build cycles, further reducing the environmental impact. This efficiency in material usage positions titanium 3D printing as a more sustainable option compared to traditional methods, despite the initial energy demands associated with the technology.

Titanium 3D printing presents a mix of advantages and disadvantages. Key benefits include:

- Biocompatibility: Ideal for medical implants.

- Lightweight Strength: Offers a superior strength-to-weight ratio.

- Corrosion Resistance: High durability in harsh environments.

However, challenges such as high material costs and process complexity hinder broader adoption.

Industry experts highlight significant advancements, particularly in cost reduction and material properties.

Looking ahead, trends like advanced materials and increased automation promise to enhance the technology’s viability. The market for titanium 3D printing is projected to grow significantly, with estimates reaching $1.2 billion by 2033.

| Trend | Description |

|---|---|

| Advanced Materials | New opportunities from innovative material compositions. |

| Improved Printing Processes | Enhanced techniques for producing complex parts. |

| Eco-Friendly Practices | Cleaner production methods driven by sustainability goals. |

As the industry evolves, ongoing research and development will play a crucial role in overcoming existing challenges and unlocking the full potential of titanium 3D printing.

FAQ

What industries benefit most from titanium 3D printing?

Titanium 3D printing primarily benefits industries such as aerospace, automotive, and healthcare. These sectors leverage titanium’s lightweight strength, biocompatibility, and corrosion resistance for critical applications.

How does titanium 3D printing compare to traditional manufacturing?

Titanium 3D printing offers design flexibility and reduced material waste compared to traditional manufacturing. However, it often incurs higher material costs and longer production times.

Can titanium 3D printing produce large components?

Currently, titanium 3D printing is best suited for small to medium-sized components. The technology faces scalability limitations, making it less effective for larger parts.

What are the environmental impacts of titanium 3D printing?

Titanium 3D printing has a lower material waste percentage than traditional methods. However, it requires significant energy for production, contributing to a larger carbon footprint.

Is titanium 3D printing suitable for medical implants?

Yes, titanium 3D printing is highly suitable for medical implants due to its excellent biocompatibility. Custom implants can be tailored to individual patient needs, enhancing surgical outcomes.

What are the main challenges of titanium 3D printing?

Key challenges include high material costs, process complexity, and production speed. Skilled operators are necessary to navigate these hurdles effectively.

How does the cost of titanium powder affect production?

The high cost of titanium powder, ranging from $200 to $500 per kilogram, significantly impacts overall production costs. This expense can deter businesses from adopting titanium 3D printing for large-scale projects.

What advancements are expected in titanium 3D printing?

Future advancements may include improved materials, enhanced printing processes, and eco-friendly practices. These developments aim to reduce costs and increase the technology’s viability across various industries.