The choice between titanium and stainless steel isn’t always clear-cut. Titanium components cost up to 5 times more than similar stainless steel parts. The material weighs about 40% less and delivers comparable strength. Engineers and designers must assess this basic trade-off among several other factors.

Titanium and stainless steel differ significantly beyond cost and weight considerations. Titanium stands out with the highest strength-to-weight ratio among metallic elements. The market belongs to stainless steel, though – its 300 Series makes up over 70% of global production. Material hardness tests revealthat titanium’s tensile strength ranges from 900 to 1,200 MPa, while stainless steel ranges from 480 to 1,100 MPa. The strength comparison becomes more interesting because titanium handles extreme conditions better despite its lighter weight. Its melting point reaches approximately 1,668°C compared to stainless steel’s 1,370-1,530°C. Each metal excels in specific uses based on priorities like weight requirements, resistance to corrosion, temperature tolerance, or budget limits.

Material Composition and Grades

The way titanium and stainless steel are made up explains their different behaviors in real-life applications. When you know their grades and what they’re made of, you can pick the right metal for your project.

Titanium Grades: CP1, CP2, Grade 5 (Ti-6Al-4V)

Titanium comes in two main types: commercially pure titanium and titanium alloys. Unlike other metals, you can use titanium in its almost pure form.

Commercially Pure (CP) titanium gets stronger as the grade number goes up:

- CP Grade 1 bends easily and fights off corrosion well. You’ll find it in chemical production equipment and medical implants.

- CP Grade 2 is known as the “workhorse” of titanium. It’s a bit stronger than Grade 1 but just as good at resisting corrosion. Aerospace and marine industries love using it.

- CP Grade 3 beats both Grade 1 and 2 in strength and flexibility. It works great when you just need medium strength with good corrosion resistance.

Grade 5 (Ti-6Al-4V) is the most popular titanium alloy out there. It makes up about half of all titanium used worldwide. This alpha-beta alloy contains about 6% aluminum and 4% vanadium. These additions help it handle heat better and make it three times stronger with an ultimate tensile strength of 150 ksi.

Stainless Steel Grades: 304, 316, 410, 17-4 PH

Stainless steel starts with iron and carbon. Adding chromium and nickel, plus other elements, gives it its special properties.

Grade 304 rules the market with a 50% share of all stainless steel. As an austenitic (300 series) steel, it contains 18-20% chromium and 8-10.5% nickel by weight. This go-to grade resists corrosion well and shapes easily. You’ll see it everywhere, from food service to outdoor fixtures and high-wear spots.

Grade 316 takes what’s good about 304 and makes it better by adding 2-3% molybdenum. This boost makes it even tougher against corrosion, especially in salty environments.

Grade 410 is part of the martensitic family and can have up to 1.2% carbon. It’s super hard and strong with decent corrosion resistance. That’s why it works so well for cutlery and industrial equipment.

17-4 PH (precipitation hardening) stainless contains 15-17.5% chromium, 3-5% nickel, and 3-5% copper. This mix creates incredible strength and hardness while fighting off corrosion well. Aerospace companies and manufacturers of high-performance parts rely on it.

Elemental vs Alloyed: Pure Titanium vs Chromium-Nickel Steel

These metals are different at their core. Titanium is a pure metallic element (symbol: Ti) that works well either pure or mixed with other elements. Even the “pure” grades have tiny amounts of oxygen, nitrogen, carbon, hydrogen, and iron that affect how they behave.

Stainless steel isn’t an element – it’s an alloy that starts with iron and needs at least 10.5% chromium. Chromium creates a protective layer that stops rust and corrosion. Adding nickel, manganese, and molybdenum gives it extra special properties.

This basic difference shows up in how these metals work. Titanium naturally fights off corrosion because of what it is, while stainless steel needs its special mix of elements to stay rust-free.

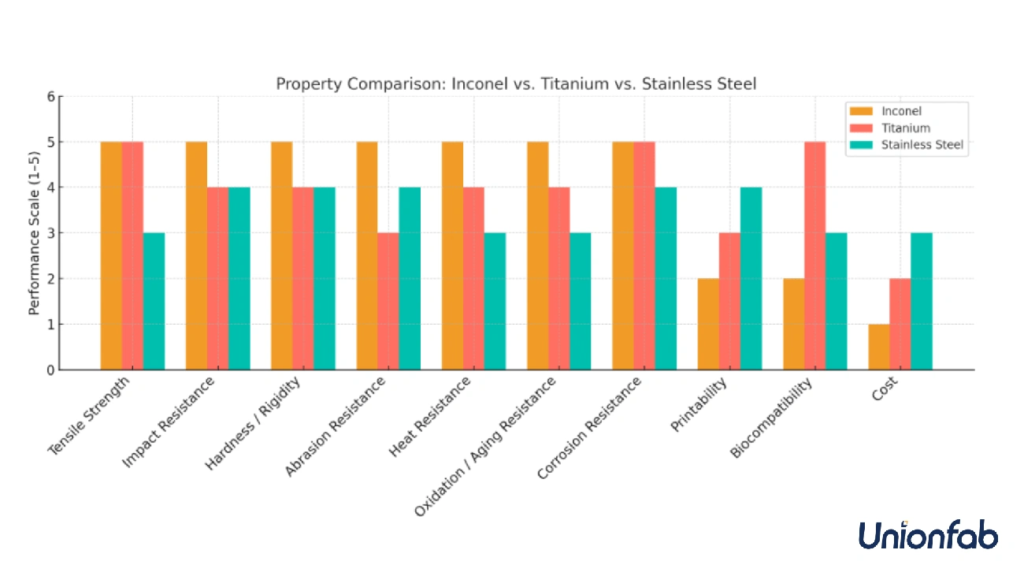

Mechanical Properties Comparison

Engineers often choose between titanium and stainless steel based on their mechanical properties. These materials have unique advantages that come from their structural characteristics.

Tensile Strength: 900–1200 MPa vs 480–1100 MPa

Grade 5 titanium alloys (Ti-6Al-4V) have tensile strength between 900 and 1,200 MPa. Stainless steel ranges from 480 to 1,100 MPa. Some high-grade stainless steels match titanium’s strength, but standard grades fall short. This makes titanium a better choice for applications that need high strength with low weight. Yes, it is worth noting that specialty stainless steel alloys can reach 2,000 MPa, which goes beyond typical titanium values.

Yield Strength: 800–1100 MPa vs 240–800 MPa

Titanium’s yield strength ranges from 800 to 1,100 MPa, which suggests great resistance to permanent deformation. Stainless steel has a yield strength between 240 and 800 MPa. Grade 5 titanium (Ti-6Al-4V) offers 1,100 MPa yield strength, which is much higher than 304 stainless steel’s 215 MPa. This becomes a big advantage in applications with fluctuating loads.

Titanium vs Steel Strength-to-Weight Ratio

Some stainless steel grades might have better absolute strength, but titanium wins in the strength-to-weight ratio. Titanium’s density is about 4.5 g/cm³, making it 42% lighter than steel at 7.8 g/cm³. Pure titanium matches some steels’ strength at just 40% of their weight. A steel part might be 5% stronger than a similar titanium one, but the titanium version weighs 40% less.

Titanium Hardness vs Stainless Steel: 250–400 HB vs 150–400 HB

Brinell hardness tests show titanium ranges from 250 to 350 HB, while stainless steel varies between 150 and 400 HB. Titanium measures 180-400 HV on the Vickers scale, and stainless steel shows 150-300 HV. Standard titanium alloys have Rockwell hardness around 30-40 HRC, but medium-carbon alloy steels can reach 50-60 HRC.

Elastic Modulus: 110 GPa vs 200 GPa

Titanium has an elastic modulus of 110-120 GPa, much lower than stainless steel’s 200-210 GPa. This means titanium is twice as flexible as steel. Titanium’s lower modulus works better for stress distribution, vibration dampening, and fatigue resistance. Steel’s higher elastic modulus makes it a better choice for applications that need structural rigidity and stiffness.

Looking at mechanical properties alone, titanium shines in strength-to-weight ratio and fatigue resistance. Stainless steel proves better for absolute strength and structural rigidity.

Corrosion and Temperature Resistance

Environmental performance makes titanium stand out from stainless steel more than almost anything else. These materials shine in challenging conditions but work differently and with varying success rates.

Corrosion Resistance in Saltwater and Chloride Environments

Titanium shows remarkable immunity to saltwater environments. Its corrosion rates reach just 0.0005 mm/year in seawater. This protection comes from titanium’s passive oxide layer that forms right away when it meets oxygen. Stainless steel depends on its chromium content to create a protective layer. This layer works well in many cases but fails in environments rich in chlorides. The gap between these materials grows even wider under harsh conditions. Titanium can handle 10% hydrochloric acid at 35°C with minimal damage, while most stainless steels start breaking down in similar conditions.

Oxidation Resistance at High Temperatures

Titanium stays strong at temperatures up to about 600°C. Above this point, it starts pulling in oxygen and nitrogen from the air, which can make it brittle. Stainless steel keeps its properties across a wider temperature range. It works well from extremely cold temperatures up to about 800-900°C, depending on the type. Titanium alloys create a thick oxide film below 550°C that stops further oxidation.

Melting Point: 1668°C vs 1370–1530°C

Titanium’s melting point is 1668°C, which is higher than stainless steel’s range of 1370–1530°C. This higher threshold lets titanium stay strong in conditions where stainless steel might start to weaken. Despite that, special grades of stainless steel often work better for long-term high-temperature uses beyond titanium’s comfort zone.

Biocompatibility: Titanium in Medical Implants

Titanium beats stainless steel in biocompatibility thanks to its oxide layer’s special properties. Research shows that pure titanium and Ti-6Al-4V alloy have much lower passive currents and higher breakdown potentials. They resist pitting both in lab tests and living tissue. Titanium also helps with osseointegration – the connection between bone and implant. This explains why titanium-based hip implants have a 95% success rate after 10 years.

Fabrication and Machinability

Manufacturing choices between titanium and stainless steel can make or break your project. Each material comes with its own manufacturing challenges that shape both costs and timelines.

Weldability: Inert Gas Welding vs MIG/TIG

Titanium needs extra care during welding because it reacts quickly with oxygen, nitrogen, and carbon as temperatures rise. Most welders use gas tungsten arc welding (GTAW) with titanium in a controlled inert gas environment. The metal’s heat-affected zone becomes brittle without proper shielding, and welds often fail.

Stainless steel is much easier to work with during welding. You can weld it with almost any arc method, including MIG and TIG techniques. Common filler rods like ER308L and ER309 create strong joints between stainless steel parts. This makes stainless steel a better choice for projects that need complex joining.

Machining Difficulty: Tool Wear and Speed

Working with titanium is tough, mainly because it doesn’t conduct heat well. The cutting edge holds about 80% of the heat generated during machining. This means you need:

- Slower cutting speeds (20-40 m/min) with faster feed rates

- Tools that keep moving to avoid work hardening

- Special cooling methods to handle heat

Stainless steel lets you work faster with cutting speeds up to 100 m/min. Both metals still face issues with galling and work hardening. Grade 303 stainless steel works best for machining because it contains sulfur.

Casting and Forming: Hot vs Cold Working

You’ll need vacuum or argon-arc melting at around 1,660°C to cast titanium. This calls for special equipment because of titanium’s high melting point and reactivity.

Stainless steel is easier to cast. It works with standard methods like investment or sand casting at temperatures between 1,370-1,540°C. More shops can work with stainless steel because it needs lower temperatures and the process is well-known.

Surface Treatments: Anodizing vs Passivation

Each metal gets its own type of surface treatment. Titanium usually gets anodized—an electric process that builds up its natural oxide layer. This helps fight corrosion and lets you add color.

Stainless steel goes through passivation—a chemical process that cleans free iron and other contaminants from its surface. This creates a protective oxide shield against corrosion. Both treatments boost performance, but titanium’s anodized surface works better for medical uses.

Cost, Availability, and Use Cases

Money often decides whether titanium or stainless steel makes more sense for a project.

Material Cost: $35/kg vs $1.5/kg

Titanium comes with a hefty price tag of $35 to $50 per kilogram. Stainless steel costs nowhere near as much at just $1 to $1.50 per kilogram. We needed complex processes to extract titanium that use lots of energy and special equipment. This price difference makes stainless steel a natural choice for prototypes, non-critical parts, or budget-conscious projects.

Availability of Alloys and Grades

A resilient infrastructure of global supply chains makes stainless steel easy to find. You can get different grades like 304, 316, 430, and specialty alloys such as 17-4 PH for various uses. Titanium’s niche market status means you’ll need special suppliers, which adds time to getting your materials.

Applications: Aerospace, Medical, Automotive, Construction

Each material shines in its own industry:

Titanium leads in:

- Aerospace: Aircraft engines, frames, fasteners

- Medical: Implants (over 90% success rate), dental applications

- Marine: Ship components, underwater pipes, desalination systems

Stainless steel rules in:

- Construction: Structural frames, HVAC systems (75% of consumer goods)

- Automotive: Exhaust systems, brake components

- Food processing: Kitchen appliances, tableware

Environmental Impact and Recyclability

Both metals can be recycled completely. This recycling cuts down CO2 emissions significantly. Aluminum scrap recycling reduces emissions by 92% compared to raw production. Copper scrap recycling lowers CO2 output by 65%. Titanium needs more energy to produce at first, but its longer service life usually makes up for this drawback.

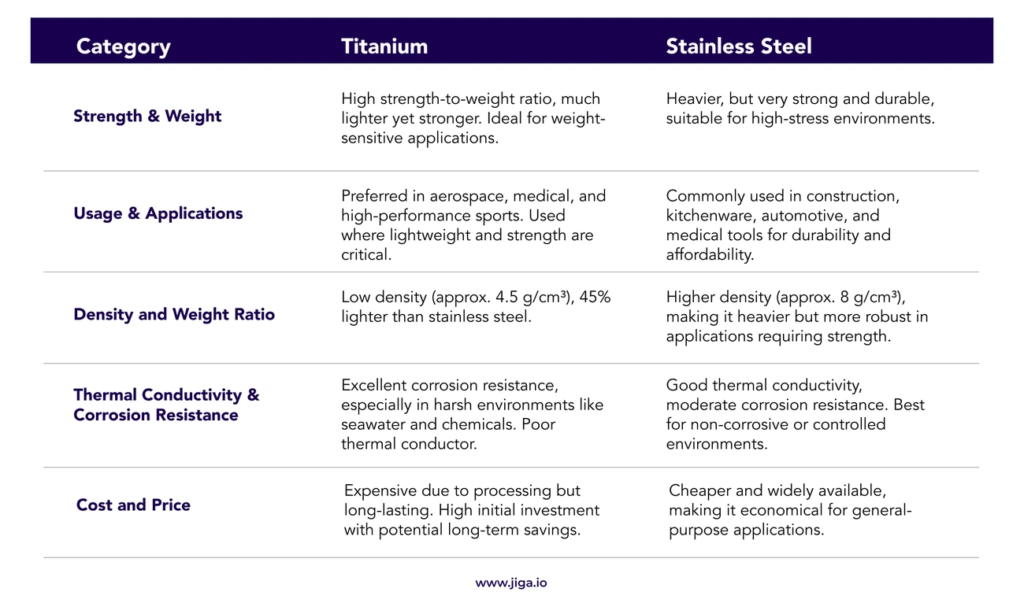

Comparison Table

| Characteristic | Titanium | Stainless Steel |

|---|---|---|

| Mechanical Properties | ||

| Tensile Strength | 900-1,200 MPa | 480-1,100 MPa |

| Yield Strength | 800-1,100 MPa | 240-800 MPa |

| Elastic Modulus | 110-120 GPa | 200-210 GPa |

| Hardness (Brinell) | 250-400 HB | 150-400 HB |

| Melting Point | 1,668°C | 1,370-1,530°C |

| Physical Properties | ||

| Density | 4.5 g/cm³ | 7.8 g/cm³ |

| Weight Comparison | 40% lighter than steel | Base reference |

| Material Composition | ||

| Base Material | Pure elemental titanium | Iron-chromium alloy |

| Common Grades | CP1, CP2, Grade 5 (Ti-6Al-4V) | 304, 316, 410, 17-4 PH |

| Corrosion Resistance | ||

| Saltwater Corrosion Rate | 0.0005 mm/year | Variable (less resistant) |

| Temperature Tolerance | Effective up to 600°C | Effective up to 800-900°C |

| Manufacturing | ||

| Welding Requirements | Strict inert gas environment | Multiple welding methods possible |

| Machining Speed | 20-40 m/min | Up to 100 m/min |

| Surface Treatment | Anodizing | Passivation |

| Practical Considerations | ||

| Cost (per kg) | $35-50 | $1-1.50 |

| Market Availability | Limited, specialized suppliers | Accessible to more people |

| Main Applications | Aerospace, Medical, Marine | Construction, Automotive, Food Processing |

| Recyclability | 100% recyclable | 100% recyclable |

Conclusion

A deep dive into titanium and stainless steel reveals a simple truth: your project’s specific needs determine the best choice. Without doubt, titanium shines with its exceptional strength-to-weight ratio, unmatched corrosion resistance, and superior biocompatibility. These qualities make it perfect for aerospace, medical implants, and marine applications. The premium features come at a price, though – titanium parts cost 5 times more than stainless steel alternatives.

Stainless steel weighs more but delivers excellent strength, versatility, and economical solutions. You’ll find it works best when budget matters more than weight. The material proves easier to work with, too. It needs simpler welding requirements and lets you machine parts faster than titanium’s demanding production process.

Your specific application needs should guide the choice between these materials. Projects that need the best corrosion resistance, lightweight construction, and biocompatibility justify titanium’s higher cost. Stainless steel makes more sense when durability, heat resistance, and cost efficiency top your priority list.

Engineers should match these trade-offs with their project requirements carefully. A 40% weight reduction might be crucial for aerospace parts, but barely matters for stationary industrial equipment. Titanium’s superior resistance to saltwater becomes vital for marine uses, yet adds unnecessary cost for indoor applications.

The best material choice doesn’t come from picking an overall winner. It comes from matching material properties to what your application needs. Both metals keep improving through new alloys and manufacturing methods. They expand their uses while keeping their unique advantages. The right choice depends on a full analysis of performance needs, environmental conditions, budget limits, and manufacturing capabilities. This helps determine whether titanium or stainless steel better fits your project’s goals.

Key Takeaways

Understanding the fundamental differences between titanium and stainless steel helps engineers make informed material selection decisions based on project-specific requirements.

• Cost vs Performance Trade-off: Titanium costs 5x more than stainless steel ($35-50/kg vs $1-1.50/kg) but offers 40% weight reduction with comparable strength.

• Superior Strength-to-Weight Ratio: Titanium delivers tensile strength of 900-1,200 MPa at just 4.5 g/cm³ density, making it ideal for aerospace and weight-critical applications.

• Corrosion Resistance Champion: Titanium exhibits exceptional saltwater resistance (0.0005 mm/year corrosion rate) and biocompatibility, perfect for marine and medical applications.

• Manufacturing Complexity: Titanium requires specialized welding in inert gas environments and slower machining speeds (20-40 m/min vs 100 m/min for steel).

• Application-Specific Selection: Choose titanium for aerospace, medical implants, and marine environments; select stainless steel for construction, automotive, and food processing, where cost-effectiveness matters most.

The optimal choice depends on balancing performance requirements against budget constraints—titanium excels when weight, corrosion resistance, and biocompatibility are critical, while stainless steel dominates cost-sensitive applications requiring durability and ease of fabrication.

FAQs

Q1. Why might someone choose titanium over stainless steel for a project? Titanium is preferred when weight reduction is crucial, as it’s 40% lighter than steel while maintaining comparable strength. It also excels in corrosion resistance and biocompatibility, making it ideal for aerospace, medical, and marine applications.

Q2. What are the main drawbacks of using titanium compared to stainless steel? The primary disadvantages of titanium are its higher cost (about 5 times more expensive than stainless steel) and more complex manufacturing processes. It requires specialized welding techniques and slower machining speeds, which can increase production time and costs.

Q3. How do titanium and stainless steel compare in terms of strength? Titanium generally offers a higher strength-to-weight ratio, with tensile strengths ranging from 900-1,200 MPa. Stainless steel’s tensile strength varies from 480-1,100 MPa. However, some specialized stainless steel alloys can match or exceed titanium’s strength.

Q4. In which environments does titanium outperform stainless steel? Titanium significantly outperforms stainless steel in saltwater and other corrosive environments. It has a corrosion rate of just 0.0005 mm/year in seawater, making it excellent for marine applications. It also performs better in medical implants due to its biocompatibility.

Q5. How do the manufacturing processes differ between titanium and stainless steel? Titanium requires more specialized manufacturing processes. It needs strict inert gas environments for welding and slower machining speeds (20-40 m/min). Stainless steel is more forgiving, allowing various welding methods and faster machining speeds (up to 100 m/min), making it easier and often more cost-effective to work with.