Manufacturers create Titanium Bike Parts using distinct methods. Additive manufacturing, or 3D printing, builds components layer by layer. Prominent techniques include Direct Metal Laser Sintering (DMLS), Cold Metal Fusion (CMF), and Laser Powder Bed Fusion (LPBF). In contrast, machining removes material from a solid block in a subtractive process. The fundamental difference lies in material addition versus material removal. Design complexity, performance requirements, and production costs significantly influence the selection of either manufacturing approach.

Key Takeaways

- 3D printing builds titanium parts layer by layer. Machining removes material from a solid block.

- 3D printed parts can be as strong as machined parts. They need special treatment after printing.

- 3D printing makes complex shapes easily. Machining struggles with very detailed designs.

- Machining creates very precise parts. It also makes surfaces very smooth.

- 3D printing is good for custom parts and small orders. Machining is better for many standard parts.

- 3D printing wastes less material. Machining creates more scrap metal.

- Combining both methods works best. 3D printing makes the basic shape. Machining adds the final touches.

Material Properties of Titanium Bike Parts

Strength and Integrity of Titanium Bike Parts

Anisotropy in 3D Printed Titanium Bike Parts

3D printed components often exhibit anisotropy. This means their material properties, such as strength, vary depending on the direction of the applied force relative to the print layers. The layer-by-layer manufacturing process creates a distinct internal structure. This structure can lead to different strengths along the build direction compared to perpendicular directions. For instance, a part might be stronger when loaded parallel to the layers than when loaded perpendicular to them.

| Material Type | Tensile Strength (MPa) | Yield Strength (MPa) |

|---|---|---|

| 3D Printed Titanium (SLM) | 1035 | 998 |

| Properly Processed 3D Printed Ti-6Al-4V | 950-1100 | N/A |

| Traditional Forged Titanium | 900-1050 | N/A |

Properly processed 3D printed Ti-6Al-4V achieves tensile strengths ranging from 950-1100 MPa. This range compares favorably to traditional forged titanium, which typically falls between 900-1050 MPa. Post-processing, such as Hot Isostatic Pressing (HIP), is crucial for 3D printed parts. It removes internal porosity and enhances fatigue strength. This allows 3D printed components to match or even exceed the performance of traditionally manufactured parts.

Homogeneity in Machined Titanium Bike Parts

Machined components, conversely, typically display greater homogeneity. They start from a solid block of material, like a forged billet. This initial material possesses a uniform grain structure and consistent properties throughout. Machining removes material without altering this fundamental internal structure. Therefore, machined parts generally exhibit consistent strength and integrity in all directions.

Fatigue Resistance for Titanium Bike Parts

Layer Adhesion in Additive Titanium Bike Parts

Fatigue resistance in 3D printed parts depends heavily on the quality of layer adhesion. Micro-defects or incomplete fusion between layers can act as stress concentrators. These areas become initiation points for cracks under cyclic loading. Poor layer adhesion can significantly reduce the fatigue life of a component. However, manufacturers employ specific post-processing techniques to mitigate these issues. For example, 3D printed titanium bike parts, specifically dropouts, undergo heat treatment to enhance their fatigue strength. This process results in a part achieving at least 99.5% density compared to a CNC-machined billet 6/4 part. It is considered equally strong and durable.

Grain Structure in Subtractive Titanium Bike Parts

Machined parts benefit from the inherent grain structure of the raw material. The manufacturing process preserves this structure. This consistent grain orientation contributes to predictable and often superior fatigue resistance. Machining does not introduce new interfaces or potential weak points like layer boundaries. This results in a more uniform response to cyclic stresses.

Thermal and Residual Stress in Titanium Bike Parts

Heat Dissipation in 3D Printed Titanium Bike Parts

The 3D printing process involves localized melting and rapid cooling of titanium powder. This rapid thermal cycling can induce significant residual stresses within the part. Uneven heat dissipation during printing contributes to these internal stresses. These stresses can lead to warping or cracking if not properly managed. Post-print heat treatments are often necessary to relieve these residual stresses.

Stress Relief in Machined Titanium Bike Parts

Machining generally introduces less residual stress into components compared to 3D printing. The material removal process generates heat, but it is typically more controlled and localized. While some surface stresses can occur from cutting forces, they are usually less severe and more predictable. For highly critical Titanium Bike Parts, manufacturers may still perform stress relief annealing after machining to ensure optimal performance and dimensional stability.

Design Flexibility for Titanium Bike Parts

Complex Geometries for Titanium Bike Parts

Organic Shapes and Lattice Structures for Titanium Bike Parts

3D printing offers unparalleled freedom in design. Manufacturers can create organic shapes and intricate lattice structures. This capability allows for completely hollow structures and complex internal geometries. Engineers can also integrate internal cable routing and custom mounts directly into parts. These designs optimize material use and enhance performance, often leading to lighter and stronger components.

Machining Limitations for Complex Titanium Bike Parts

Machining faces inherent limitations when creating complex shapes. It struggles with complicated geometries and large dimensions. Achieving narrow tolerances on intricate features can be challenging. Furthermore, maintaining the strength of thin walls during the machining process presents difficulties. These constraints often force designers to simplify parts or use multi-component assemblies.

Internal Channels in Titanium Bike Parts

Integrated Fluid Paths in 3D Printed Titanium Bike Parts

3D printing excels at creating internal channels and integrated fluid paths. This technology transcends traditional manufacturing constraints. It enables the creation of complex geometries and internal channels that optimize fluid flow, leading to superior performance. Engineers can embed cable channels, cooling systems, or sensor mounts directly into parts. This integration reduces assembly steps, minimizes failure points, and improves structural efficiency. For example, internal pneumatic channels or cable paths can be printed directly into components. This eliminates the need for extra tubing or brackets, reducing weight and simplifying assembly. The ability to produce intricate internal structures also enhances thermal management and fluid dynamics.

Multi-Axis Machining Challenges for Titanium Bike Parts

Creating internal channels with machining presents significant challenges. Multi-axis machining can produce some internal features, but it often requires complex setups and specialized tools. Deep or winding internal paths are particularly difficult, if not impossible, to achieve without splitting the part into multiple sections. This limitation often restricts designers to simpler, more accessible internal geometries.

Part Consolidation for Titanium Bike Parts

Reducing Assembly Steps for 3D Printed Titanium Bike Parts

Part consolidation is a major benefit of 3D printing. Design freedom allows for topology-optimized structures and combined parts. This approach removes failure points and significantly reduces overall weight. For instance, topology optimization can reduce weight by 21%. Integrated features eliminate welded joints, contributing to lighter components and simplified assembly. Consolidating multiple mechanical functions into single units reduces complexity, improves reliability, and lowers manufacturing costs for Titanium Bike Parts.

Traditional Multi-Part Titanium Bike Assemblies

Traditional manufacturing methods often require assembling multiple individual parts. This process involves numerous steps, such as welding, bolting, or bonding. Each connection point represents a potential failure point and adds to the overall weight and complexity of the final assembly. This contrasts sharply with the integrated designs possible with 3D printing.

Precision and Surface Finish of Titanium Bike Parts

Dimensional Accuracy of Titanium Bike Parts

Post-Processing for 3D Printed Titanium Bike Parts

3D printing often requires additional steps to achieve precise dimensions. The layer-by-layer process can introduce slight variations. These variations mean that fresh-off-the-printer parts rarely meet final specifications directly. Manufacturers use post-processing techniques like machining or grinding to refine the dimensions. This ensures the part fits correctly and functions as intended.

Tight Tolerances in Machined Titanium Bike Parts

Machining excels at producing parts with high dimensional accuracy. It removes material from a solid block using precise cutting tools. This method allows for very tight tolerances. Machined components consistently meet exact specifications. The inherent rigidity of the machining process contributes to this precision.

Surface Roughness of Titanium Bike Parts

As-Printed Surface Texture of Titanium Bike Parts

3D printed titanium parts typically have a rougher surface directly after printing. Fresh-off-the-printer titanium parts, relevant to 3D printed bike components, typically exhibit surface roughness (Ra) values ranging from 4 to 10 μm. Some original LPBF components can have Ra values up to 25 μm. This texture comes from the layered manufacturing process.

| Part Type | Ra Value (μm) |

|---|---|

| As-built DMLS specimens (3D Printed) | ~13.76 |

| Original LPBF components (3D Printed) | Up to 25 |

Machined Surface Quality of Titanium Bike Parts

Machining generally produces a smoother surface finish. The cutting action of tools creates a more uniform texture.

| Machining Type | Ra Value (μm) |

|---|---|

| As machined | 3.2 |

| Smooth machined | 1.6 |

A smooth machined surface can achieve an Ra value of 1.6 μm. This is significantly smoother than most as-printed surfaces.

Post-Processing Options for Titanium Bike Parts

Polishing and Grinding for Additive Titanium Bike Parts

Titanium components require extensive post-processing to meet final specifications and performance standards after 3D printing. Surface finish presents a challenge. Overhangs often result in rougher surfaces. This necessitates more post-treatments that increase manufacturing costs. Raw 3D-printed titanium parts often have a rough surface. They require finishing to improve appearance, durability, and performance. Unionfab offers various finishing solutions, including:

- Polishing

- Grinding

- Sandblasting

- Shot Peening

- Painting

- Powder Coating

Surface Treatments for Machined Titanium Bike Parts

Machined parts may also undergo surface treatments. These treatments enhance specific properties. They can improve corrosion resistance or alter appearance. Examples include anodizing or specialized coatings. These treatments are often less about correcting initial roughness and more about adding functional or aesthetic benefits.

Cost and Production Volume for Titanium Bike Parts

Setup Costs for Titanium Bike Parts Manufacturing

Machine Investment for 3D Printing Titanium Bike Parts

3D printing titanium components requires a substantial initial investment in machinery. Industrial-grade metal 3D printers, especially those capable of processing titanium, carry high price tags. These machines often include advanced laser systems, inert gas environments, and sophisticated control software. The cost of these specialized printers can range from hundreds of thousands to millions of dollars. This significant upfront capital expenditure impacts the overall cost structure for manufacturers.

Tooling and Fixturing for Machining Titanium Bike Parts

Machining titanium parts also involves setup costs, primarily for tooling and fixturing. Manufacturers need specialized cutting tools made from hard materials like carbide. Titanium’s hardness and tendency to work-harden quickly wear down standard tools. Custom fixtures are often necessary to securely hold complex Titanium Bike Parts during the machining process. While these costs can be considerable, they are generally lower than the initial investment for a high-end metal 3D printer.

Material Waste in Titanium Bike Parts Production

Powder Recycling in Additive Titanium Bike Parts

3D printing offers significant advantages in material utilization. The process uses titanium powder, and manufacturers can often recycle unused powder. This reduces waste. Some projects demonstrate waste reduction from 80% with traditional methods to less than 5% with 3D printing. This efficiency is crucial due to titanium’s high cost. The buy-to-fly ratio for 3D printing ranges from 3:1 to 12:1. This indicates much less material is purchased than ends up in the final part.

Chip Generation in Subtractive Titanium Bike Parts

Machining is a subtractive process. It generates a significant amount of material waste in the form of chips. Traditional machining can result in up to 90% material waste. The buy-to-fly ratio for traditional machining is typically 12:1 to 25:1. This means manufacturers buy a large amount of raw material, but only a small fraction becomes the final product. Recycling these titanium chips is possible, but it adds processing steps and costs.

Production Volume Break-Even Points for Titanium Bike Parts

Low Volume Customization with 3D Printed Titanium Bike Parts

3D printing excels in low-volume production and customization. The technology allows for rapid design iterations and the creation of unique, bespoke components without expensive tooling changes. This makes it ideal for prototyping, custom bike frames, or limited-edition parts. The cost per part remains relatively consistent regardless of design changes, making it economical for small batches.

High Volume Efficiency with Machined Titanium Bike Parts

Machining becomes more cost-effective at higher production volumes. Once manufacturers establish tooling and programming, the per-part cost decreases significantly with increased output. The efficiency of automated CNC machines allows for rapid production of identical parts. This makes machining the preferred method for standardized components produced in large quantities.

Lead Times for Titanium Bike Parts

Rapid Prototyping with 3D Printed Titanium Bike Parts

3D printing significantly accelerates product development cycles. It enables rapid prototype production, testing, and optimization. This technology enhances production efficiency through automation, minimizes manual intervention, and lowers costs. It also facilitates innovative designs, including complex hollow structures and topology optimization, leading to lighter and stronger components. Unlike traditional methods that involve multiple processes like casting, CNC machining, and welding, additive manufacturing allows for integrated formation. This saves materials and avoids risks such as welding-induced deformation and fatigue.

For small-batch customized products, 3D printing shortens product delivery time and enhances production efficiency. This approach considers the need for lightness and weight reduction in cycling products. It allows for one-piece forming of complex structures and supports high-end customization. It also helps avoid the high manufacturing costs and environmental pollution associated with single-piece or small-lot production using traditional methods. For example, manufacturers can produce a batch of bicycle seat stay yokes quickly:

| Method | Component | Quantity | Time | Efficiency vs. Traditional |

|---|---|---|---|---|

| 3D Printing | Bicycle Seat Stay Yoke | 38 pieces | 24 hours | >60% more efficient than casting |

Production Scheduling for Machined Titanium Bike Parts

Machining processes often involve longer lead times, especially for custom or low-volume components. The need for specific tooling, programming, and setup contributes to this duration. While efficient for mass production, custom machined Titanium Bike Parts require careful scheduling. This includes design finalization, material procurement, and allocation of machine time.

For highly customized components, lead times can extend considerably:

| Item | Lead Time |

|---|---|

| Custom Frames/Bikes | >18 months |

| Custom Forks/Components | 9-12 months |

These extended periods reflect the intricate planning and sequential steps involved in traditional manufacturing. Each stage, from design to final machining, adds to the overall production timeline. This contrasts with the integrated and faster turnaround possible with 3D printing for prototypes and small batches.

Sustainability of Titanium Bike Parts Manufacturing

Energy Consumption for Titanium Bike Parts

Power Usage of 3D Printers for Titanium Bike Parts

Metal 3D printers consume significant energy. These machines require high-power lasers or electron beams to melt titanium powder. They also need energy to maintain inert gas environments and precise temperature controls within the build chamber. This ensures the quality and integrity of the printed parts. The entire printing process, from pre-heating to post-cooling, demands a consistent energy supply.

Energy for Machining Titanium Bike Parts

Machining titanium also involves substantial energy consumption. CNC machines use powerful motors to drive cutting tools and move workpieces. These operations generate considerable heat, requiring energy for cooling systems. The hardness of titanium means cutting tools must work harder, increasing the energy needed for material removal. Both manufacturing methods are energy-intensive, but their energy demands stem from different operational principles.

Material Utilization for Titanium Bike Parts

Near-Net Shape Manufacturing of Titanium Bike Parts

3D printing excels in material utilization through near-net shape manufacturing. This process builds parts layer by layer, adding material only where necessary. Techniques like topology optimization and lattice design allow engineers to create highly efficient structures. These designs significantly reduce the amount of raw material needed. For example, 3D printed components can be up to 50% lighter than their machined counterparts while maintaining structural integrity. This demonstrates that 3D printing creates parts with considerably less material waste.

Material Removal Rates for Machined Titanium Bike Parts

Machining is a subtractive process. It starts with a solid block of material and removes unwanted portions to achieve the final shape. This method inherently generates more scrap material in the form of chips. While manufacturers can recycle these chips, the initial material removal rate means a larger volume of raw material is consumed compared to the final part’s weight.

Waste Management for Titanium Bike Parts

Powder Handling and Disposal for 3D Printed Titanium Bike Parts

Managing waste from 3D printing titanium involves specific challenges. Metal powders are often discarded in landfills. They are considered hazardous, difficult to handle, and expensive to transport, especially sludges with high water content. Despite being hazardous, these metal powders are recyclable. Metal 3D printer waste can be classified as RCRA hazardous due to characteristics like flammability, reactivity, or toxicity. Specific hazardous wastes include:

- Reactive metal particulates: These can be explosive or flammable. Inhalation of certain powders, such as nickel, cobalt, or chromium, can cause health issues. Improper disposal can contaminate soil or water.

- Used powders & residues: These are often classified as hazardous industrial waste due to oxidized material, loose particles, or contaminants.

- Post-processing wastes: Supports, failed prints, and sludge from cleaning are hazardous if they contain metal alloys or specific chemicals.

Research focuses on deoxidizing and remanufacturing used titanium powders and scrap for 3D printing. Companies like 6K can take certified chemistry materials from machining operations, along with 3D printing support structures, used powders, and out-of-spec parts. They convert these into suitable AM powder, achieving a 100% yield. This process significantly reduces landfill waste and cuts energy costs associated with transportation, mining, and refining.

Metal Chip Recycling for Machined Titanium Bike Parts

Machining generates metal chips as a byproduct. Manufacturers can collect and recycle these titanium chips. This process involves sorting, cleaning, and melting the chips to create new raw material. While recycling metal chips is common practice, it requires additional energy and resources for collection, processing, and remanufacturing.

Applications and Hybrid Approaches for Titanium Bike Parts

When 3D Printing Excels for Titanium Bike Parts

Custom Frames and Components for Titanium Bike Parts

3D printing offers significant advantages for creating highly customized bike components. Manufacturers can produce fully customized frames tailored precisely to individual riders’ body measurements and riding styles. This ensures a perfect fit and allows for unique designs. The technology also enables innovative designs like organic shapes and lattice structures, which improve aerodynamics and overall performance. For instance, the MYTHOS Axion handlebar, a customizable 3D printed titanium component, gives riders and bike fitters precise control over every aspect of their fit with millimeter precision. This eliminates the need for compromise in adjustments.

Lightweighting and Optimization of Titanium Bike Parts

3D printing provides unprecedented freedom to create and innovate, overcoming traditional manufacturing limitations. This geometric freedom, combined with topology optimization and simulation analysis, allows for significant weight reduction without compromising strength. Engineers achieve this through lattice structures and thin-wall optimization, leading to advancements in lightweight frame design. The technology also enables integrated structures. Complex assemblies, typically requiring multiple welded components, can be produced as a single, seamless unit. This enhances overall stiffness, reliability, and design precision. Furthermore, 3D printing facilitates streamlined geometries and concealed cable routing, drastically reducing aerodynamic drag and meeting high-performance demands for bicycles. A 3D-printed titanium pedal crank, for example, achieved a 40-50% weight reduction compared to conventional pedal cranks.

When Machining is Preferred for Titanium Bike Parts

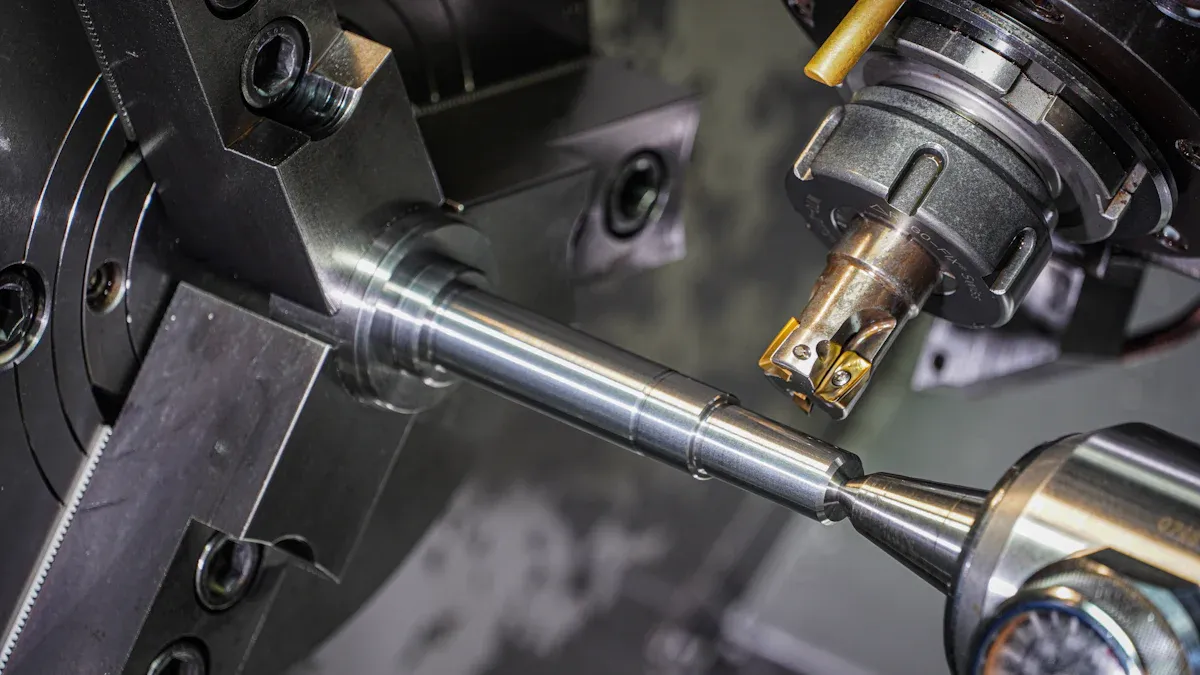

High-Stress Titanium Bike Components

Machining remains the preferred method for high-stress components. CNC machining allows for high-level precision and customization of bike parts. Multi-axis CNC milling achieves precise cutting and shaping, enabling the production of complex components. CNC turning is cost-effective for simpler customized parts like hubs or cranks, creating high-precision curved components. CNC bike parts offer superior precision and accuracy compared to conventionally produced components. This ensures repetitive production without dimensional errors and tight tolerances for perfect fitting and reliable performance. Titanium spindles, for instance, are favored for their lightweight and robust nature, enhancing performance and longevity in high-end bicycles. Titanium’s ability to withstand high stresses and temperatures contributes to better overall performance.

Standardized Titanium Bike Parts

Machining is highly efficient for producing standardized components in large volumes. Once manufacturers establish tooling and programming, the per-part cost decreases significantly with increased output. This makes machining the ideal method for producing consistent, identical parts like standard axles, bolts, or brake calipers.

Combining Technologies for Titanium Bike Parts

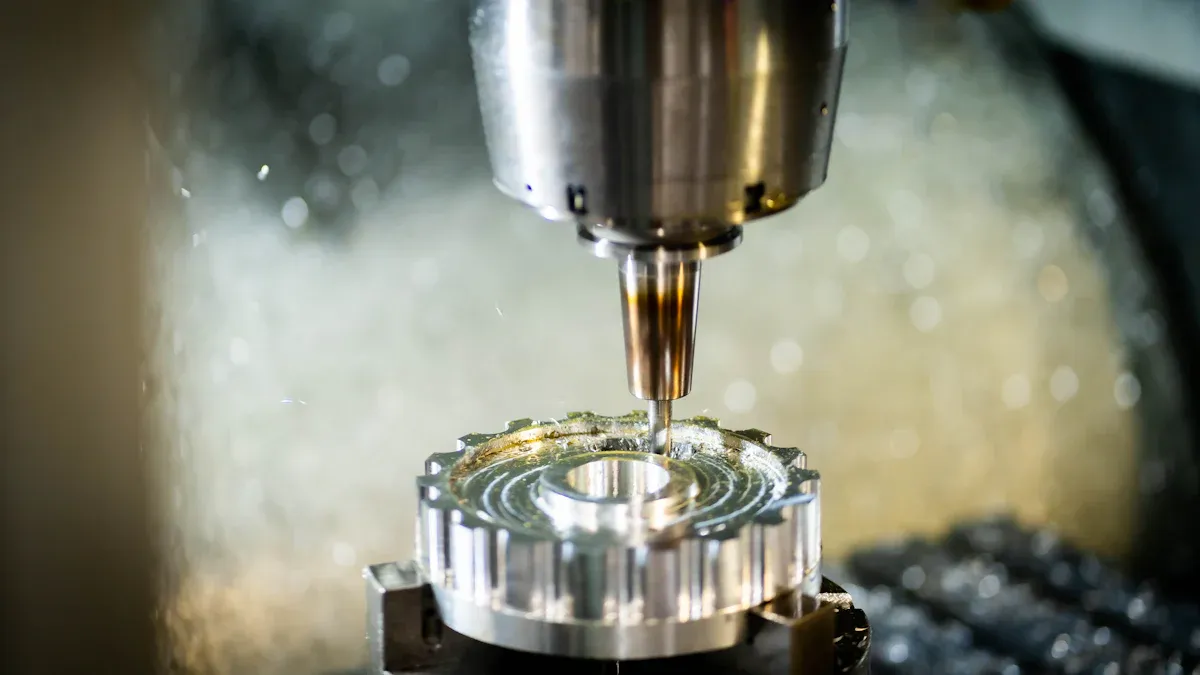

3D Printed Near-Net Shape with Machined Finish for Titanium Bike Parts

A hybrid approach often leverages the strengths of both technologies. 3D printing can create a near-net shape part, minimizing material waste and enabling complex internal geometries. Subsequently, machining refines critical surfaces and features to achieve tight tolerances and a superior surface finish. This combination optimizes material use while ensuring precision.

Hybrid Manufacturing Workflows for Titanium Bike Parts

Manufacturers increasingly adopt hybrid workflows. They might 3D print a complex frame junction and then machine the interfaces for other components. This approach allows designers to exploit the geometric freedom of additive manufacturing for specific sections while relying on the precision and surface quality of machining for critical connection points.

3D printing excels in creating complex, lightweight structures and offers unparalleled customization for low-volume production. It allows for designs impossible with traditional methods, enabling personalized and functional bike components. Machining provides an exceptional strength-to-weight ratio, corrosion resistance, and durability, making it ideal for high-stress, standardized components in larger volumes. Manufacturers strategically select methods for specific Titanium Bike Parts based on design complexity, required precision, and production scale. The future involves integrating both technologies. Innovations in aerospace-grade alloys like Scalmalloy and advanced titanium alloys, combined with 3D printing’s customization capabilities, will drive lighter, stronger, and more personalized bike components.

FAQ

What is the fundamental difference between 3D printing and machining titanium bike parts?

3D printing builds titanium bike parts layer by layer. This process adds material. Machining removes material from a solid block. This process subtracts material.

Do 3D-printed titanium bike parts have the same strength as machined ones?

Properly processed 3D printed titanium can match or exceed machined parts in strength. Post-processing, such as Hot Isostatic Pressing (HIP), is crucial for 3D printed components.

Why do 3D printed titanium parts often have a rougher surface finish?

The layer-by-layer manufacturing process creates a distinct surface texture. This results in a rougher finish compared to machined surfaces. Manufacturers often require post-processing to smooth these parts.

Which manufacturing method is better for complex titanium bike part designs?

3D printing excels at creating complex geometries. It allows for organic shapes, lattice structures, and intricate internal channels. Machining faces limitations when producing highly intricate designs.

Is 3D printing or machining more cost-effective for titanium bike parts production?

3D printing is cost-effective for low-volume customization and rapid prototyping. Machining becomes more efficient for high-volume production of standardized parts.

How does material waste compare between 3D printing and machining titanium bike parts?

3D printing uses near-net shape manufacturing, minimizing material waste. Manufacturers can often recycle unused powder. Machining generates significant chip waste from material removal.

Can manufacturers combine 3D printing and machining for titanium bike parts?

Yes, hybrid approaches are common. 3D printing creates near-net shapes with complex features. Machining then refines critical surfaces for precision and a superior finish.