Modern bicycle frames that weigh less than a kilogram (2.2 lbs) show how optimized design has transformed cycling manufacturing. E-bikes were almost non-existent in the market 25 years ago, but sales hit 3.7 million units in 2019. Experts project these numbers to quadruple to 17 million by 2030. This rapid growth makes engineers rethink how they approach bicycle components.

Design optimization isn’t just about cutting weight. Engineers must balance the product’s structure, material selection, and stress distribution to boost performance based on real-life priorities. They now utilize advanced manufacturing methods like 3D printing titanium “nodes” that adapt to each rider’s needs. This optimized approach helps create efficient metal parts that deliver peak performance with minimal materials. Modern design tools make it easier to integrate electronics and motors into drivetrains, which speeds up innovation throughout the industry.

The meaning of optimized design has changed a lot over the last several years, especially when you have companies like Airbus cutting an aircraft partition’s weight by 45% while keeping its strength and function intact . This piece explores how engineers cut titanium bike components by 40% through innovative optimization techniques without sacrificing performance.

Design Goals Behind the 40% Weight Reduction

Weight reduction in high-performance bike components creates a complex engineering challenge. Titanium bike parts now weigh 40% less thanks to careful design that puts performance first. Engineers needed to build parts that stayed strong and rigid with much less material.

Balancing Rigidity and Mass in Titanium Components

Titanium’s unique properties make it perfect for lightweight parts. The Ti-6Al-4V alloy (containing 6% aluminum and 4% vanadium) weighs just 4.43g/cm³—about 43% lighter than standard steel. Yet it stays strong with tensile strength over 1000MPa, matching high-strength alloy steels. This amazing strength-to-weight ratio makes it the top choice for aerospace and high-performance cycling.

Engineers must balance several competing factors when designing better titanium components. Stiffness plays a key role in power transfer since a flexible frame loses energy through bending during pedaling. In stark comparison to this, most marketing claims miss the mark—energy stored in frame flexing comes back when the frame rebounds, affecting how responsive the bike feels rather than its efficiency.

Stiffness matters most for structural strength. One engineer puts it simply: “a bike has two wheels and a rider and you need to keep them all in the same place relative to each other”. Too much flex could make the bike hard to control during fast descents or heavy braking. Metal fatigue becomes crucial too—each flex could lead to failure over time. Titanium helps here with its “fatigue limit,” which means it can flex forever below certain stress levels without breaking.

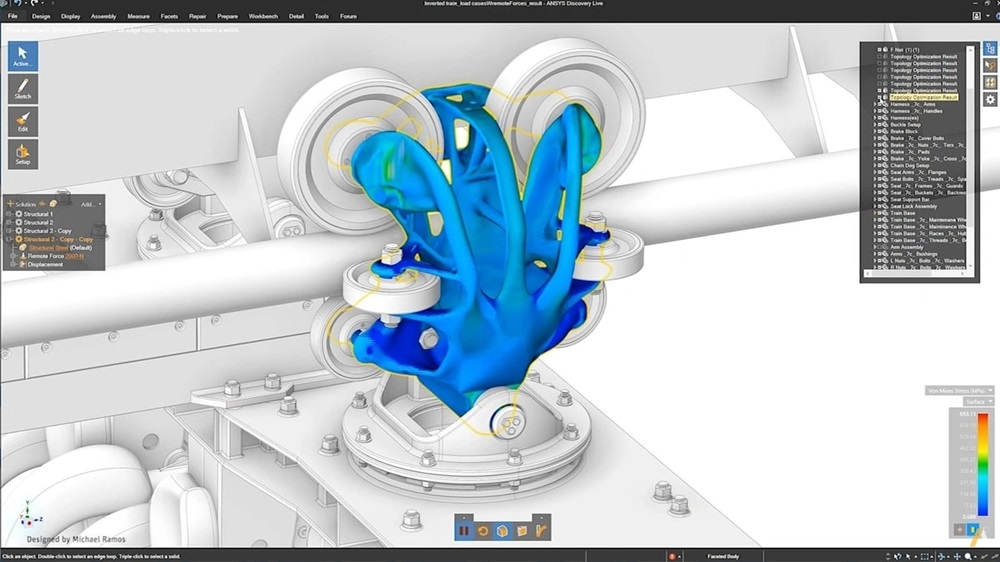

Engineers use topology optimization—a computer-aided design technique—to get maximum stiffness with minimum weight. A bicycle seat post bracket showed this works well, dropping from 360g to 200g (45% lighter) while staying just as strong. Yes, it is possible to cut weight by up to 70% from original designs in some cases.

Original Constraints in Traditional Crankarm Design

Traditional crankarm designs hit many roadblocks that stopped them from getting better. Old manufacturing methods relied on standard tubes and welding, which limited design options. This led to poor material placement and extra weight.

Traditional titanium component design faced these challenges:

- Wall thickness variations: Even tiny thickness differences (.010″ or 0.25mm) could ruin parts

- Internal diameter precision: Changes of just .005″ (0.13mm) affected how parts worked by a lot

- Built-in stresses: Titanium 6/4 is “notoriously prone to built-in stresses,” so setup must be perfect to prevent warping

- Manual processing requirements: Old designs needed lots of extra work, making them costly and slow to produce

Designers had no choice but to add extra material “just in case,” which made parts heavier than needed. The radical alteration toward better process design changed everything. Designers now use generative design tools to add material only where it needs to be strong, instead of starting with a solid block and cutting away.

Crankarms need different levels of stiffness depending on direction. Parts must fight both bending forces (based on second moment of area, I) and torsional forces (based on polar second moment of area, J). Modern optimization helps engineers place material exactly where it makes parts strongest, rather than spreading it evenly.

Generative Design Workflow Using Fusion 360

Generative design brings a fundamental change to how engineers create components. Traditional methods start with drawings, but this process starts by defining parameters and constraints. AI then determines the best possible forms. SRAM worked with Autodesk to use Fusion 360’s generative design features. This ended up creating titanium crankarms that weighed 20% less and showed twice the strength of traditional versions.

Setting Load Cases and Boundary Conditions

Ground conditions need an accurate representation for any problem-based solution to work. The finite element analysis (FEA) modeling process needs three main types of input data:

- Geometry data: Creates the finite elements that represent frame components

- Material properties: Has elastic modulus, shear modulus, Poisson ratio, and mass density

- Loading information: Shows magnitude, direction, and where forces are applied

The right loading information plays a vital role in getting reliable results. Engineers looked at various load cases to assess structural strength. These included static start-up forces, horizontal and vertical impacts, braking scenarios, and steady-state pedaling conditions. The team applied boundary conditions as restraints to key spots like bottom brackets, steering tubes, and seat posts. They used rigid links to copy real component interactions.

The crankarm project needed specific obstacle regions where the solver couldn’t add material. These included areas where the crankarm might hit other components during rotation. Forces from side components and shock absorbers’ reaction forces determined the central components’ loading.

AI-Driven Geometry Generation for Crankarms

Fusion 360 creates thousands of possible solutions in just hours once parameters are set. It finds options that match the requirements best. SRAM could explore many design options that weren’t possible before. The AI system assessed each design based on manufacturing needs. This created very different solutions depending on whether CNC machining or additive manufacturing would be used.

The system created designs that “no human ever would have thought of”. These computer-generated designs ranged from traditional-looking crankarms with holes to futuristic truss-like structures. Each version went through strength-to-weight ratio analysis and material placement optimization.

SRAM’s design engineers found that generative design “shaved considerable time off the crank-arm project”. Fusion 360’s cloud features let teams in California and Chicago work together easily, even during the pandemic shutdown.

Combining Multi-Part Assemblies into Single Units

Generative design excels at combining multiple components into single units. This makes assembly easier while improving product quality, function, and life span. Part consolidation helps manufacturers who create complex products with challenging shapes. They get benefits like lighter weight, lower assembly costs, less waste, better reliability, and improved performance.

The combination process has four main steps. Teams select the assembly, use generative design to test hundreds of options, redesign parts using the data, and prove the new design through FEA before 3D printing. General Motors showed this approach by turning eight parts into one 3D-printed seat bracket. The new part weighed 40% less yet showed 20% more strength.

This optimized design approach helps engineers solve complex challenges much faster than before. Fusion 360’s AI tools let global teams work together naturally. They can tackle problems like “how do we make that part lighter, yet more performant than its predecessor, and consolidate some of its elements so it’s easier to build, thus cheaper?”.

Material Optimization: Why Titanium Was Chosen

Titanium stands out in bicycle manufacturing as a premium material, though production challenges have limited its use over the years. Engineers assess titanium’s properties against project needs because material choice directly affects how much weight they can reduce.

Strength-to-Weight Ratio of Grade 5 Titanium

Grade 5 titanium (Ti-6Al-4V) is a great choice for high-performance cycling parts. This alloy combines 90% titanium, 6% aluminum, and 4% vanadium to create an exceptional strength-to-weight ratio. Tests show it has a tensile strength of about 1035 MPa while weighing just half as much as steel parts. Among all metals used in bicycle manufacturing, titanium’s strength-to-weight ratio ranks highest.

Grade 5 titanium strikes the perfect balance between stiffness and weight reduction. The material weighs just 4.51 g/cm³—about 60% of steel’s weight—yet keeps its structural integrity. Parts made from this material work well in extreme temperatures and resist breaking down even after countless stress cycles, which matters a lot for bike components.

Reducing Waste Through Simulation-Aware Design

Modern design software helps cut down titanium waste. The old way involved cutting away material from solid blocks, which wasted expensive titanium. Now, engineers use software that knows material properties, tests performance under stress, and works within manufacturing limits to create better designs.

This approach works great with titanium parts because the material goes only where needed. Reynolds 3D printed titanium dropouts show this benefit—they build up instead of cutting down, which creates less waste while staying strong and light. These parts blend naturally with frame tubes, which saves framebuilders time.

Cost vs Sustainability Trade-offs in Titanium Use

Two main things have held back titanium’s wider use in bicycle parts: it costs too much and affects the environment. The traditional Kroll process uses lots of energy, driving up prices and carbon emissions. A titanium bicycle frame costs $3,000-$4,000, while carbon fiber frames run $1,500-$2,000.

New technologies tackle both these issues at once. Canyon works with IperionX to develop greener manufacturing using the HAMR-process instead of the Kroll method. This new approach makes titanium recycling possible and reduces environmental impact.

Titanium parts last 20-30 years, much longer than other materials, which helps justify the higher upfront cost. The metal naturally resists rust, so it doesn’t need paint or coatings, which makes it even better for the environment throughout its life.

Additive Manufacturing for Final Part Realization

Modern manufacturing needs specialized techniques to turn optimized designs into real components with complex shapes. The quickest way to create titanium bicycle parts with intricate, material-efficient structures is Laser Powder Bed Fusion (L-PBF) technology.

3D Printing Titanium Nodes with L-PBF

L-PBF systems create components by melting thin layers of titanium powder with a focused laser beam. Parts are built layer by layer, which enables the creation of internal structures that were impossible before. Manufacturing facilities now work with remarkable efficiency. They print 38 components in 24 hours, which has boosted productivity by 60% compared to traditional casting methods. The process takes place in an inert gas environment, usually argon. This prevents titanium’s highly reactive nature from causing oxidation that could reduce the material’s ductility and fatigue resistance.

Support Structure Optimization for Print Success

Support structures are vital for successful titanium L-PBF printing. These temporary structures prevent parts from collapsing or deforming. However, they create challenges like higher material costs, complex post-processing, and possible surface damage. Engineers must balance these factors through orientation design variables that reduce supports while keeping structural integrity. Designers work to find the best build angles that eliminate overhangs where possible. Parts are positioned to minimize support structure needs. This streamlined process design cuts waste, reduces production time, and improves surface quality.

Post-Processing: Heat Treatment and Surface Finishing

Titanium components need specific post-processing to reach their best mechanical properties. Stress relief heat treatment happens first at 600-800°C in argon for 1-2 hours while parts stay attached to the build plate. Critical components undergo Hot Isostatic Pressing at 920-930°C under 100-120 MPa pressure for 2-4 hours to eliminate internal porosity. These treatments create exceptional mechanical properties. Tensile strength reaches 1035 MPa, yield strength hits 998 MPa, and elongation at break touches 13.5%. Surface finishing might include tumbling or vibratory polishing to achieve surface roughness values as low as 0.22 μm. This greatly enhances fatigue resistance by removing potential crack initiation sites.

Performance Validation and Testing Results

Testing rigorously is essential to create a successful, optimized design process. The titanium bike components that were 40% lighter went through extensive performance evaluation to check their ground capabilities against theoretical predictions.

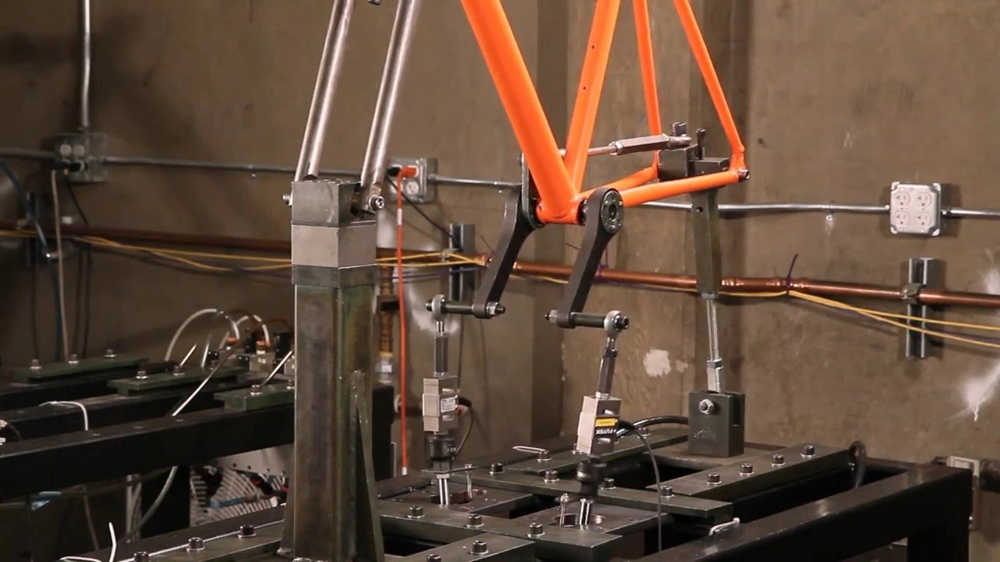

Fatigue Testing Under Simulated Ride Conditions

SRAM’s engineers tested components to assess their durability and suitability. The tests put the parts through thousands of kilometers of simulated riding cycles. ZwickRoell testing machines were used to confirm finite element method (FEM) models by exploring mechanical responses under loads of all types. This method helped optimize the process and cut test times by 80 percent. The accuracy of testing and crack detection also improved. Athletes tried physical prototypes in both lab and ground conditions. They shared their thoughts on stiffness, comfort, and overall performance.

Stiffness-to-Weight Ratio Benchmarking

A critical performance metric for lightweight components is the stiffness-to-weight ratio. This ratio determines how well titanium bike parts transfer power from rider to drivetrain. Titanium structures with good design show exceptional “fatigue limit” properties. They can flex forever without failing when stresses stay below critical thresholds. Tests of stiffness-to-weight showed that titanium components last remarkably long with proper welding. This comes from their natural flexibility (twice that of steel) and better resistance to side impacts.

Comparative Analysis: Optimized vs Legacy Crankarms

Static and dynamic experiments on the optimized crankarm design matched simulation predictions excellently. FEA results showed maximum stress rose from 41.2% to 61.5% of the material’s yield strength. This was slightly above the target optimization value of 50%. A special testing apparatus confirmed these findings. It checked the entire range of motion at 15-degree intervals with strain gages and dial indicators. Theory matched practice closely. The data confirmed that topology optimization software works well to optimize metal additive manufacturing parts.

Conclusion

Making titanium bike components 40% lighter marks a breakthrough in cycling manufacturing. Engineers used generative design to create parts that kept their strength while weighing much less. They placed materials strategically instead of spreading them evenly, which challenged old design methods.

AI-powered tools in Fusion 360 made this possible. The software created thousands of designs based on real-life stress conditions. It produced shapes that no human designer would think of. These computer-generated structures put material only where needed, which cut down excess weight.

Grade 5 titanium (Ti-6Al-4V) was the best material choice because of its strength-to-weight ratio. Titanium used to be hard to work with and expensive. New additive manufacturing methods like Laser Powder Bed Fusion (L-PBF) solved these problems. Printing complex shapes directly from optimized designs has changed how manufacturing works.

Post-processing is vital too. Heat treatments make the parts stronger. Surface finishing helps them last longer. These treatments help the parts perform better even with less material.

Thorough testing showed these lightweight parts work well in real-life conditions. The parts’ stiffness-to-weight ratio proved that well-designed titanium structures last long and stay strong.

These optimization methods work in other industries too. Aircraft makers cut weight while keeping structures strong, which uses less fuel and helps the environment. This new way of designing shows how engineering has changed. Engineers now put material exactly where it needs to be instead of cutting it away from solid blocks.

These optimized titanium bike parts show more than just weight reduction. They show a new way of thinking about design. Engineers now start with what they need the part to do and let computers figure out the best shape. This approach will keep changing manufacturing in all industries, creating products that weigh less, stay stronger, and help the environment.

Key Takeaways

Engineers achieved a remarkable 40% weight reduction in titanium bike components by combining AI-powered generative design with advanced manufacturing techniques, proving that optimization goes far beyond simple material removal.

• Generative design revolutionizes component creation: Fusion 360’s AI generates thousands of design iterations in hours, placing material only where structurally needed rather than using traditional uniform distribution methods.

• Grade 5 titanium offers unmatched performance: Ti-6Al-4V alloy provides exceptional strength-to-weight ratio at 4.43g/cm³ density—43% lighter than steel while maintaining 1000+ MPa tensile strength.

• Additive manufacturing enables complex geometries: Laser Powder Bed Fusion (L-PBF) 3D printing creates intricate internal structures impossible with traditional manufacturing, achieving 60% productivity increases.

• Rigorous testing validates lightweight performance: Components underwent extensive fatigue testing and stiffness-to-weight benchmarking, confirming that optimized parts maintain structural integrity despite significant mass reduction.

• Part consolidation reduces complexity: Multi-component assemblies can be consolidated into single units, simplifying assembly while improving reliability and reducing manufacturing costs.

This breakthrough demonstrates how combining computational design tools with advanced materials and manufacturing techniques can achieve previously impossible performance improvements, setting new standards for lightweight engineering across industries.

FAQs

Q1. What is generative design and how was it used to create lighter bike parts? Generative design is an AI-powered approach that creates thousands of potential designs based on set parameters and constraints. For the titanium bike parts, engineers used Fusion 360’s generative design capabilities to explore multiple design iterations, resulting in components that were 20% lighter and twice as strong as traditional versions.

Q2. Why was titanium chosen as the material for these optimized bike components? Grade 5 titanium (Ti-6Al-4V) was selected due to its exceptional strength-to-weight ratio. It offers a density of just 4.43g/cm³—about 43% lighter than steel—while maintaining tensile strength exceeding 1000MPa. This allows for components that are structurally sound yet considerably lighter than traditional materials.

Q3. How were the optimized titanium parts manufactured? The parts were manufactured using Laser Powder Bed Fusion (L-PBF), an additive manufacturing technique. This process builds components layer by layer by selectively melting thin layers of titanium powder with a focused laser beam, allowing for the creation of complex internal structures that were previously impossible to produce.

Q4. What kind of testing did the lightweight components undergo? The optimized components underwent extensive performance validation, including fatigue testing under simulated ride conditions, stiffness-to-weight ratio benchmarking, and comparative analysis against legacy designs. Both static and dynamic experiments were conducted to verify that the parts met or exceeded performance requirements despite their reduced weight.

Q5. What are the broader implications of this weight reduction achievement? This achievement demonstrates the potential of combining AI-powered design tools with advanced materials and manufacturing techniques to create significantly lighter yet stronger components. The approach has applications beyond cycling, with potential benefits in industries like aerospace, where weight reduction can lead to improved fuel efficiency and reduced environmental impact.