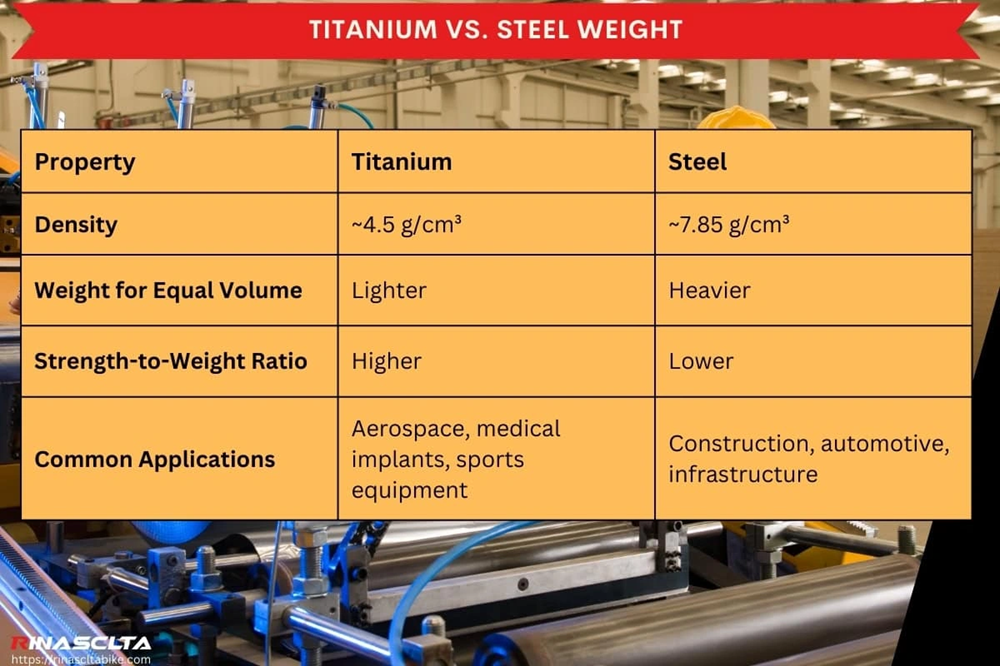

Titanium stands out as nature’s champion among metals with its unmatched strength-to-density ratio . This metal matches steel’s strength but weighs much less at 4.5 g/cm³, while steel tips the scales at 7.8 g/cm³ . Such an impressive mix of strength and light weight has made titanium a prized material in many industries.

Engineers have found that titanium weighs about half as much as iron . The metal weighs 60% more than aluminum but packs more than double the punch of common aluminum alloys like 6061-T6 . Titanium’s specific strength reaches an impressive 288 kNm/kg , which makes it perfect for projects that need stronger and lighter alloys . The metal also shrugs off corrosion better than most, even in the nastiest environments . These features help explain why titanium beats steel hands down in applications where weight matters but toughness can’t be compromised.

Titanium Density and Its Role in Material Selection

Titanium’s remarkable density of 4.51 g/cm³ places this metal right between lightweight aluminum and heavier steel. This physical characteristic is the foundation of titanium’s exceptional performance when weight matters in many industries.

Titanium density: 4.51 g/cm³ vs other metals

Pure titanium has a density of 4.51 g/cm³, while commercially pure grades come in slightly lower at 4.4-4.5 g/cm³. Titanium alloys range from 4.4-4.8 g/cm³ based on their composition. These numbers show titanium weighs about 40% less than steel (7.8-8.0 g/cm³) but weighs twice as much as aluminum (2.7 g/cm³).

You can see the density differences clearly here:

| Material | Density (g/cm³) |

|---|---|

| Titanium | 4.5 |

| Steel | 7.8-8.0 |

| Aluminum | 2.7 |

Grade-2 Titanium weighs in at 4.51 g/cm³ compared to carbon steel’s 7.85 g/cm³. The Ti-6Al-4V alloy (Grade 5) is even lighter at 4.42-4.43 g/cm³, making it perfect for applications where weight matters most.

How low density affects structural design

Titanium’s relatively low density substantially changes how engineers approach structural design. They can build lightweight structures that stay durable. This advantage becomes vital in aerospace applications where titanium creates lighter, smaller parts that handle heavy loads effectively.

Automotive engineers use titanium components to cut overall weight while keeping structural integrity, which helps improve fuel efficiency. Marine applications benefit from titanium’s winning combination of lower weight and resistance to corrosion.

Specific strength: strength-to-weight ratio explained

Specific strength—the ratio of material strength to density—stands out as one of titanium’s most valuable features. Titanium alloys show better specific strength values than many structural metals. To name just one example, Ti-6Al-4V (Grade 5) has a specific strength of 226, which easily beats both maraging steel (202) and stainless steel varieties (75-105).

This property makes titanium incredibly efficient when designs need both weight reduction and strength. The metal’s atomic structure creates a unique blend that’s stronger than aluminum yet lighter than steel. Titanium components can support more weight compared to their own mass than steel parts. This explains why high-performance applications where weight matters choose titanium as their go-to material.

Thermal and Chemical Behavior of Titanium

Titanium stands apart from other common metals due to its low thermal conductivity of 11.4 W/m·K. This unique property creates both challenges and benefits for engineers. Heat management becomes a significant factor in many applications. The metal’s poor heat distribution concentrates temperature at the cutting tool instead of spreading it through the workpiece. This concentration can reduce tool life and might damage material integrity.

Thermal conductivity: 11.4 W/m·K and its implications

Titanium’s thermal conductivity differs dramatically from that of other engineering metals. Steel conducts heat four times better than titanium’s 11.4 W/m·K. Engineers need special cooling techniques to work with this metal, but its low conductivity works well in thermal barrier applications. The metal maintains its properties remarkably well from -270°C to +400°C, making it perfect for extreme environments.

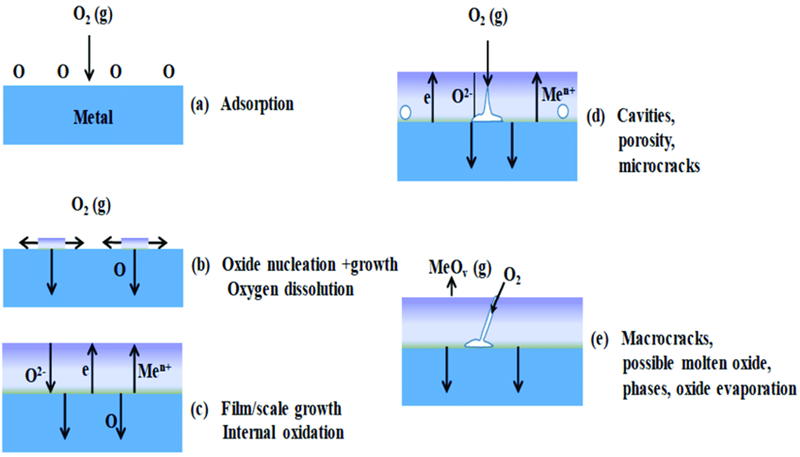

Oxide layer formation and corrosion resistance

The metal’s most remarkable chemical property lies in its protective oxide film formation. Titanium creates a thin, tough TiO2 layer when exposed to oxygen or air. This original film starts at just 1-2 nanometers thick and grows to about 25 nanometers over four years. Titanium dioxide makes up most of this oxide layer that acts as a passive barrier, stopping further oxidation and providing exceptional protection against corrosion.

The self-healing oxide film helps titanium resist aggressive substances that would destroy other metals. The metal shows remarkable resistance to seawater, chlorine compounds, and aqueous metal chloride solutions without pitting or stress corrosion cracking.

Reactivity with acids and high-temperature gasses

Titanium resists oxidizing acids like nitric acid across a wide range of temperatures and concentrations. The metal reacts faster with hydrofluoric acid, even in weak solutions. Users should never expose titanium to hydrofluoric acid or fluoride solutions with a pH below 7.

Heat increases titanium’s reactivity significantly. The metal burns in nitrogen above 800°C to form titanium nitride, which leads to embrittlement. Oxygen reactions occur at 610°C in pure oxygen and at 1,200°C in air, creating titanium dioxide.

Mechanical Properties That Complement Low Density

Titanium’s favorable density pairs with mechanical properties that make it valuable for critical applications. The material combines low weight with impressive strength, which makes it perfect for demanding engineering environments.

Tensile strength of pure titanium vs alloys

Pure titanium shows tensile strength from 240 MPa for grade 1 to 550 MPa for grade 4. These values jump dramatically in alloy form. Ti-6Al-4V (grade 5), a popular alloy, delivers an ultimate tensile strength of 950 MPa and yield strength of 880 MPa. Some specialized titanium alloys push even further, reaching tensile strengths above 1400 MPa. This is a big deal as it means that titanium outperforms many steel alloys while weighing much less.

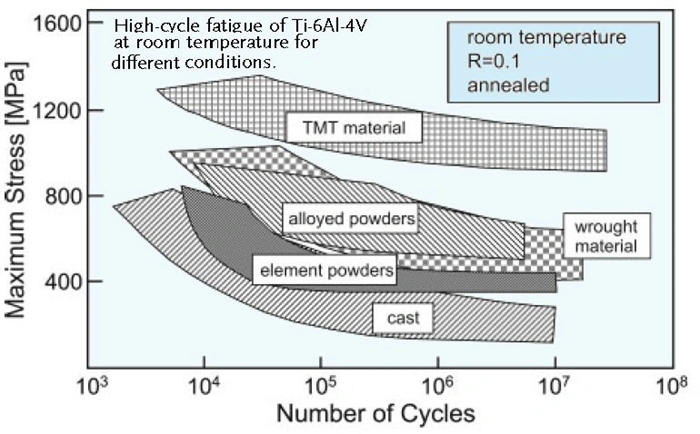

Elastic modulus and fatigue resistance

The elastic modulus ranges from 105 GPa in pure titanium to about 120 GPa in alloys. This stiffness-to-weight ratio helps create components that fight deformation while staying light. Titanium shines in fatigue performance too, with fatigue limits hitting 40-60% of tensile strength. Ti-6Al-4V alloy delivers fatigue strength of 510 MPa at 10 million cycles. These properties make it ideal for aerospace uses where high-frequency cyclic loading occurs.

Machinability and springback behavior

Despite its benefits, titanium brings manufacturing challenges. Heat concentrates at the cutting tools because of titanium’s low thermal conductivity instead of spreading through the workpiece. Pure titanium machines most easily, though machinability varies among grades. Springback remains a key factor in titanium fabrication. Research reveals faster bending speeds create more springback as the material thickness deforms unevenly. Engineers use specialized forming techniques or adjust tooling design to handle this behavior.

Why Engineers Prefer Titanium in Critical Applications

Engineers in a variety of critical industries now rely on titanium as their go-to material because it offers an exceptional mix of physical and chemical properties. The benefits of titanium’s low density become clear when you look at high-demand applications.

Aerospace: weight savings in aircraft structures

Titanium makes up about 15% of the Boeing 787 Dreamliner’s weight and 14% of the Airbus A350 XWB [3]. The material weighs 45% less than steel while matching its strength. This means aircraft components can be lighter, which helps save fuel and increases how much cargo planes can carry. Titanium also stays strong even when temperatures change drastically. That’s why it’s a great choice for crucial parts like landing gear, frames, and engine components.

Medical: biocompatibility and implant longevity

Titanium’s excellent biocompatibility comes from its passive oxide film that stops corrosion in body fluids. These implants can last between 20-50 years, and dental implants show an impressive 97% success rate after 10 years. The material’s ability to bond directly with bone tissue makes it perfect for orthopedic implants. Titanium alloys are now used in more than 95% of titanium biomedical devices.

Marine: corrosion resistance in saltwater environments

Titanium stands up to all types of corrosive attack in seawater at temperatures up to 500°F (260°C). The material doesn’t suffer from pitting, crevice corrosion, or microbiologically influenced corrosion. That’s why titanium parts have worked flawlessly in seawater for over thirty years. Water can flow past it at speeds up to 120 ft/sec without causing much erosion, which makes it ideal for marine settings.

Industrial: heat exchangers and chemical vessels

Chemical processing plants use titanium heat exchangers because they can run for over 30 years with minimal upkeep. Titanium conducts heat 50% better than stainless steel, which makes heat exchange more efficient. You’ll find titanium tubing in power plants, refineries, and desalination facilities. The original cost might be higher, but its resistance to harsh chemicals means you’ll spend less on maintenance over time.

Conclusion

Titanium is a remarkable engineering material. Its exceptional density of 4.5 g/cm³ matches the strength of much heavier metals. Engineers can design lightweight structures that don’t compromise on durability or performance. The specific strength of titanium alloys outperforms other metals substantially. Ti-6Al-4V, with a rating of 226, proves stronger than both maraging and stainless steel.

The metal creates its own protective oxide layer that resists corrosion in extreme conditions. Titanium maintains its structural integrity in temperatures from -270°C to +400°C, making it perfect for harsh environments. While the metal’s thermal properties create some manufacturing challenges, its performance benefits make up for these obstacles.

Look at the aerospace industry to see titanium’s real-world value. Modern aircraft like the Boeing 787 Dreamliner use about 15% titanium in their construction. The medical field benefits from titanium’s compatibility with human tissue, which helps implants last for decades. Marine equipment made from titanium has worked flawlessly for over thirty years, even when constantly exposed to corrosive seawater.

Titanium’s combination of strength, low density, and resistance to corrosion makes it ideal for critical applications. Engineers need materials that reduce weight without sacrificing performance. These core qualities explain why designers choose titanium despite its cost. The long-term advantages often justify the original investment.

Key Takeaways

Understanding titanium’s unique properties reveals why engineers consistently choose this metal for critical applications where weight reduction and performance cannot be compromised.

• Titanium offers exceptional strength-to-weight ratio – At 4.5 g/cm³ density, it’s 45% lighter than steel while maintaining comparable strength, making it ideal for weight-critical applications.

• Self-healing oxide layer provides superior corrosion resistance – Titanium forms a protective TiO2 film that prevents corrosion in harsh environments, enabling 30+ years of trouble-free service.

• Biocompatibility makes it perfect for medical implants – Titanium implants can function for 20-50 years with 97% success rates due to excellent osseointegration with bone tissue.

• Aerospace industry relies heavily on titanium’s properties – Modern aircraft like the Boeing 787 use 15% titanium by weight, significantly improving fuel efficiency through weight reduction.

• Temperature stability enables extreme environment applications – Titanium maintains structural integrity from -270°C to +400°C, making it invaluable for aerospace and industrial applications.

Despite higher initial costs, titanium’s combination of lightweight properties, corrosion resistance, and long-term durability often justifies the investment through reduced maintenance and superior performance in demanding applications.

FAQs

Q1. What makes titanium a preferred choice for engineers in critical applications? Titanium’s exceptional strength-to-weight ratio, corrosion resistance, and thermal stability make it ideal for applications where weight reduction and performance are crucial. Its unique properties allow for lightweight yet durable designs in aerospace, medical, marine, and industrial sectors.

Q2. How does the density of titanium compare to other common metals? Titanium has a density of 4.5 g/cm³, which is about 45% lighter than steel (7.8-8.0 g/cm³) but heavier than aluminum (2.7 g/cm³). This low density, combined with high strength, gives titanium an excellent strength-to-weight ratio.

Q3. What are the key advantages of using titanium in medical implants? Titanium’s biocompatibility, corrosion resistance in bodily fluids, and ability to bond with bone tissue (osseointegration) make it ideal for medical implants. Titanium implants can function for 20-50 years, with dental implants showing a 97% success rate after 10 years.

Q4. How does titanium perform in marine environments? Titanium exhibits exceptional corrosion resistance in saltwater, resisting all forms of corrosive attack at temperatures up to 260°C. It’s immune to pitting, crevice corrosion, and microbiologically influenced corrosion, providing over 30 years of trouble-free service in marine applications.

Q5. What challenges does titanium present in manufacturing processes? Titanium’s low thermal conductivity concentrates heat at cutting tools during machining, which can lead to faster tool wear. Additionally, titanium exhibits springback behavior during forming processes, requiring specialized techniques or tooling design adjustments to compensate for this characteristic.