Selecting between sla-vs-fdm-3d-printing methods depends on your specific project requirements. FDM 3D printing dominates global usage, with 71% of businesses relying on it for its affordability and versatility, especially when producing large or functional parts. On the other hand, SLA, while less common, excels in precision and surface finish, making it the preferred choice for medical, dental, and highly detailed prototypes.

| Feature | FDM: Best For | SLA: Best For |

|---|---|---|

| Usage | Large, strong, cost-effective parts | Fine detail, smooth surface, precision |

| Industries | Education, engineering, prototyping | Healthcare, dental, jewelry |

Key Takeaways

- FDM 3D printing is affordable and versatile, ideal for large, strong parts and functional prototypes, while SLA offers high precision and smooth surfaces for detailed, small models.

- SLA prints deliver finer detail and better surface finish but require more post-processing and cost more in materials and maintenance than FDM.

- FDM supports a wide range of durable thermoplastic materials, making it suitable for engineering and functional parts, whereas SLA uses resin that produces more brittle but highly detailed parts.

- FDM printers generally have larger build volumes and faster setup, making them better for big or multiple parts; SLA printers excel in speed for small, intricate models but have smaller build areas.

- Choosing between SLA and FDM depends on your project needs: pick FDM for strength, cost-effectiveness, and ease of use; choose SLA for fine detail, smooth finish, and precision.

What is FDM 3D Printing?

FDM Printing Process

Fused Deposition Modeling (FDM) stands as one of the most widely used 3D printing technologies. The process begins when a spool of thermoplastic filament feeds into an extruder. The extruder heats the filament to its melting point. A computer-controlled nozzle then deposits the melted material onto a build plate, layer by layer, following the digital 3D model. The build environment maintains a controlled temperature, which helps each layer adhere properly and reduces warping. FDM technology, first trademarked by Stratasys in 1989, differs from other methods like Stereolithography (SLA) and Selective Laser Sintering (SLS). While SLA uses UV light to cure liquid resin and SLS uses lasers to sinter powder, FDM relies on melted thermoplastic filaments. This approach makes FDM more accessible and cost-effective, though it typically produces lower resolution and surface finish compared to resin or powder-based systems.

FDM Strengths

FDM 3D printing offers several advantages that make it popular for a wide range of applications:

- Speed and affordability, especially for rapid prototyping.

- Cost-effectiveness compared to other 3D printing technologies.

- Wide material compatibility, supporting thermoplastics such as ABS, PLA, Nylon, PETG, and TPU.

- Suitability for producing functional and structural parts.

- Adequate accuracy for many prototyping and functional needs, with tolerances around 0.2 mm.

- Larger build volumes, allowing for the creation of bigger parts and scalability.

These strengths make FDM a preferred choice for education, engineering, and cost-sensitive projects.

FDM Weaknesses

Despite its popularity, FDM 3D printing has notable limitations:

- Difficulty in achieving fine details and smooth surface finishes compared to resin-based methods.

- Challenges in optimizing process parameters for different materials and part types.

- Filament manufacturing issues, including the need for better material reinforcement and recycling.

- Print quality depends on machine parameters such as nozzle diameter and temperature control.

- High processing temperatures can cause thermal degradation, limiting the use of thermally sensitive materials.

- Problems with interlayer bonding and void formation, especially in fiber-reinforced composites.

These weaknesses highlight the importance of matching the technology to the specific requirements of each project.

What is SLA 3D Printing?

SLA Printing Process

Stereolithography (SLA) 3D printing uses a unique approach to create objects. The process begins with a vat filled with liquid photopolymer resin. A UV laser traces the shape of each layer, curing the resin and solidifying it. The build platform moves incrementally, allowing the laser to form each new layer on top of the previous one. This method enables the creation of highly detailed parts with smooth surfaces.

Matt Schmidt, Senior Solutions Engineer, explains that FDM uses real thermoplastic filament, while SLA relies on a liquid resin vat and UV light to cure photopolymers. This distinction in material state and curing method sets SLA apart from FDM.

The table below highlights the main differences between SLA and FDM printing processes:

| Attribute | SLA (Stereolithography) | FDM (Fused Deposition Modeling) |

|---|---|---|

| Printing Process | UV laser cures liquid resin layer by layer | Heated nozzle extrudes melted filament layer by layer |

| Material Form | Liquid photopolymer resin | Thermoplastic filament |

| Resolution and Detail | High (25–300 microns), fine features (~100 microns) | Lower (50–500 microns), minimum feature ~1 mm |

| Surface Finish | Excellent, minimal visible layers | Visible layer lines |

| Build Volume | Smaller, limited by resin vat | Larger, scalable |

| Part Strength | Weaker, photopolymer-based | Stronger, thermoplastic-based |

| Cost | Higher, specialized equipment and materials | Lower, simpler technology |

| Post-Processing | Requires cleaning and UV curing | Minimal, mostly support removal |

| Ease of Use | Needs specialized knowledge | Accessible to beginners |

SLA Strengths

SLA 3D printing offers several advantages across industries:

- High precision and smooth surface finish, ideal for detailed prototypes and models.

- Versatility in applications, including healthcare, automotive, aerospace, and architecture.

- Rapid prototyping and custom tooling, which accelerate product development.

- Ability to produce complex and intricate designs not possible with traditional manufacturing.

- Recent advancements, such as parallel processing and innovative curing methods, have improved print speed.

- Material innovations include smart resins with temperature sensitivity, biocompatibility, and flexibility.

- Companies like Ford, BMW, Airbus, and NASA use SLA to reduce time-to-market and improve efficiency.

- SLA supports emerging fields like bioprinting and space-based manufacturing.

- Environmental benefits include reduced material waste and localized production.

SLA Weaknesses

Despite its strengths, SLA 3D printing presents several challenges:

- High printer and resin costs, often two to four times more than FDM alternatives.

- Extensive post-processing requirements, including washing, UV curing, and manual support removal.

- Toxicity concerns, as resins contain chemicals that can irritate skin, eyes, and respiratory systems, requiring careful handling.

- Mechanical limitations, such as weaker bonding between layers and lower impact resistance, make parts more brittle.

- Frequent maintenance, including cleaning resin vats, changing filters, lubricating parts, and replacing LCD screens, is necessary to maintain print quality.

sla-vs-fdm-3d-printing: Side-by-Side Comparison

Print Quality and Detail

SLA 3D printing consistently delivers higher resolution and smoother finishes than FDM. The UV laser curing process in SLA enables layer thicknesses as fine as 25 microns, producing parts that closely resemble injection-molded components. This level of detail makes SLA ideal for applications requiring high precision, such as medical implants and jewelry. FDM, on the other hand, typically achieves layer resolutions between 0.2 and 0.3 mm, with some advanced models reaching 0.02 mm vertically. However, FDM prints often display visible layer lines and are more susceptible to issues like layer shifting and misalignment, resulting in rougher surfaces.

| Printer Type | Typical Layer Resolution | Notable Example | Additional Details |

|---|---|---|---|

| FDM | 0.2 to 0.3 mm (typical) | Ultimaker 2: 0.02 mm vertical resolution | Limited by nozzle size (~0.8 mm); filament width does not affect XY resolution |

| SLA | As thin as 0.025 mm | Form 2: 0.025 mm layer thickness | Resolution determined by optical spot size (e.g., 140 microns for Form 2); produces finer details and smoother surfaces |

Dimensional accuracy also favors SLA. SLA parts can achieve prototyping tolerances down to ±0.10 mm, while FDM typically offers tolerances around ±0.5 mm. Both technologies can produce anatomical models with less than ±3% dimensional error, but SLA maintains slightly tighter accuracy. Despite these advantages, SLA prints may experience warping or sagging due to peeling forces during the printing process and require skilled post-processing to remove supports and smooth surfaces. FDM provides more material and color options but generally cannot match the surface smoothness or precision of SLA.

Note: SLA excels in fine detail and surface finish, while FDM offers broader material choices and faster, less complex post-processing.

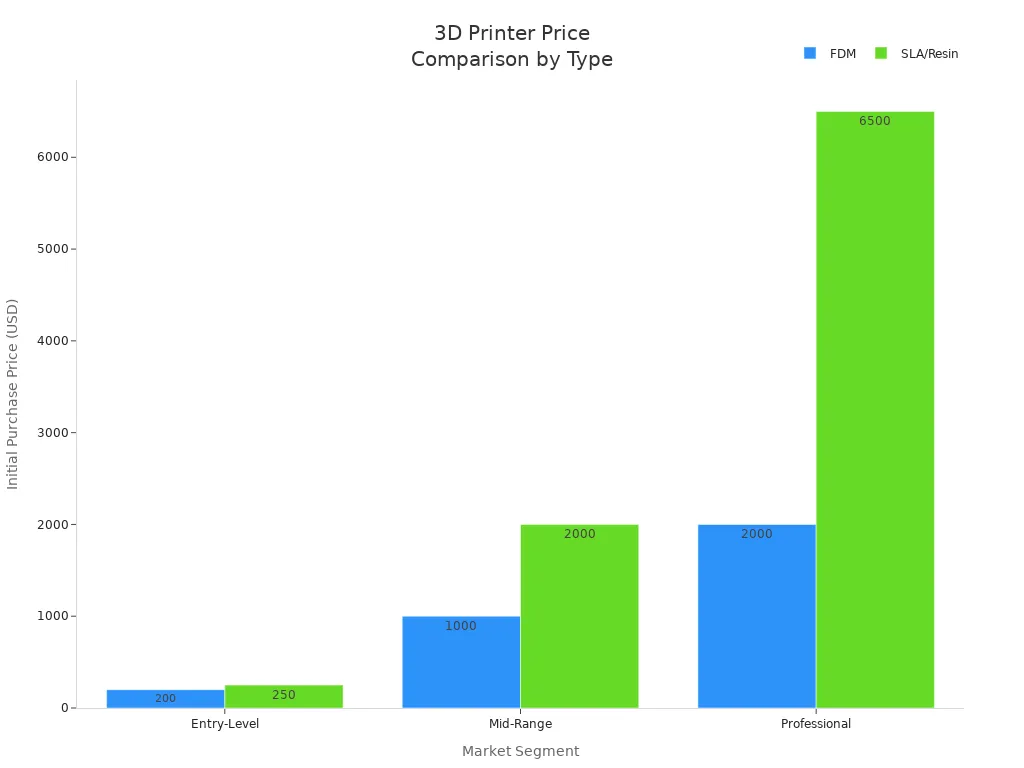

Cost and Affordability

Cost remains a critical factor in the sla-vs-fdm-3d-printing debate. FDM printers and materials are generally more affordable, making them accessible for hobbyists, educators, and businesses with budget constraints. Entry-level FDM printers start at around $200, such as the Creality Ender 3, while professional models like the Ultimaker S5 exceed $2,000. SLA printers, although available at entry-level prices of $200 to $300 (e.g., Phrozen Sonic Mini 8K S), often require a higher initial investment for mid-range and professional models, with prices reaching up to $10,000.

| Printer Type | Entry-Level Price Range | Example Model (Entry-Level) | Mid-Range Price Range | Example Model (Mid-Range) | Professional Price Range | Example Model (Professional) |

|---|---|---|---|---|---|---|

| FDM | Around $200 | Creality Ender 3 | $500 – $1,500 | Phrozen Arco (hobbyist) | $2,000+ | Ultimaker S5 |

| SLA/Resin | $200 – $300 | Phrozen Sonic Mini 8K S | $1,000 – $3,000 | Phrozen Sonic Mighty 12K | $3,000 – $10,000 | Phrozen Sonic Mega 8K V2 |

Material costs further differentiate the two technologies. FDM filaments such as PLA and ABS range from $20 to $50 per kilogram, while SLA resins start at $50 per liter and can reach $400 per kilogram for specialized applications. Maintenance costs for both printer types fall between $20 and $200 monthly, covering consumables like build plates, nozzles, and cleaning supplies. Energy consumption remains low for both, with average print times around 10 hours and electricity costs adding only a few cents per hour.

| Parameter | FDM Printing | SLA Printing |

|---|---|---|

| Material Cost | $20 – $50 per kg (PLA, PETG) | $50 per liter (entry-level resin), $150 – $400 (professional resin) |

| Energy Consumption | 50-100W per hour | 30-50W per hour |

| Electricity Cost | $0.0065 – $0.065 per hour | $0.0065 – $0.065 per hour |

| Average Print Time | 10 hours | 10 hours |

Hidden costs, such as material wastage, post-processing consumables (like isopropyl alcohol for resin cleaning), and periodic maintenance, also contribute to the total cost per print. FDM remains the more budget-friendly option for most users, while SLA justifies its higher price with superior print quality and detail.

Material Options

Material compatibility plays a significant role in the sla-vs-fdm-3d-printing comparison. FDM printers use a wide range of thermoplastic filaments, including PLA, ABS, PETG, Nylon, TPU, PC, and PEEK. These materials are familiar from injection molding and offer diverse mechanical properties, such as rigidity, flexibility, heat resistance, and impact strength. FDM parts, however, exhibit anisotropic mechanical properties due to the layered printing process, meaning their strength varies depending on print orientation.

| Material | Compatibility with FDM | Key Properties | Mechanical Performance | Ease of Printing | Heat Resistance | Impact Resistance | Layer Adhesion | Notes |

|---|---|---|---|---|---|---|---|---|

| PLA | Yes | Rigid, brittle | Moderate | Very easy | Low | Low | Moderate | Biodegradable, good UV resistance, odorless, low humidity resistance |

| ABS | Yes | Tough, heat resistant | High | Moderate | High | High | Moderate | Can be post-processed with acetone, abrasion resistant |

| PETG | Yes | Softer, chemical resistant | Moderate | Moderate | Moderate | Moderate | Moderate | Food safe, recyclable, heavier than PLA/ABS |

| Nylon | Yes | Strong, chemical resistant | High | Difficult | Moderate | Very high | Poor | Absorbs moisture, emits during printing |

| TPU | Yes | Flexible, abrasion resistant | Moderate | Difficult | Low | Very high | Moderate | Difficult to post-process, not easily glued |

| PC | Yes | Very strong, UV sensitive | Very high | Moderate | High | High | Moderate | Sterilizable, easy to post-process |

| PEEK | Yes (advanced FDM) | High rigidity, heat resistant | Very high | Difficult | Very high | High | High | Industrial use |

SLA printers use thermosetting photopolymer resins, which cure into a solid structure under UV light. These resins provide exceptional detail and smoothness but differ from thermoplastics in mechanical and thermal properties. SLA parts tend to be more brittle and less heat-resistant than FDM parts, making them suitable for applications where fine detail outweighs mechanical strength.

“Young’s Modulus As a predictable result, the specimens oriented along the Z-axis direction present the lowest rigidity of all, owing to their described brittle behaviour, and thus can be orientation defined as the most influential parameter. The highest deformation module in the elastic regime is defined by an orientation of the fibres along the Y-axis direction, because of the different pattern deposited in this direction with regards to the X-axis orientation.”

This observation highlights the anisotropic nature of FDM prints, where mechanical properties depend on print orientation. SLA prints, by contrast, have more consistent properties throughout the part but may lack the toughness of some FDM materials.

FDM’s broad material selection supports a wide range of functional and engineering applications, while SLA’s specialty resins excel in producing highly detailed prototypes, dental models, and jewelry masters.

Printing Speed

Printing speed remains a critical factor when comparing 3D printing technologies. FDM printers construct objects by extruding thermoplastic filament line by line, which often results in longer print times for complex or tall models. For a 10 cm tall object, FDM machines typically require between 3 to 8 hours, depending on the nozzle size, layer thickness, and print settings. Increasing the speed on FDM printers can lead to a noticeable drop in print quality, with more pronounced layer lines and potential defects.

SLA printers, which include resin-based systems, use a different approach. These machines cure entire layers of liquid resin at once using a UV laser or light source. As a result, SLA printers can produce similar-sized objects in about 2 to 5 hours. The print time for SLA depends mainly on the model’s height rather than its overall volume or complexity. This method allows SLA printers to maintain high detail even at faster speeds.

However, SLA prints require additional post-processing steps, such as washing and UV curing, which add 20 to 40 minutes to the workflow. FDM post-processing usually involves only support removal and light finishing, making it quicker in some cases.

| Printer Type | Average Print Time for ~10 cm Object | Notes |

|---|---|---|

| FDM | 3 to 8 hours | Print speed varies with nozzle size and layer thickness; faster speeds reduce quality |

| SLA (Resin) | 2 to 5 hours | Cures entire layers at once; post-processing adds 20–40 minutes |

Note: SLA printers generally offer faster print times for small, detailed models, while FDM provides flexibility but may require longer print durations for high-quality results.

Build Volume

Build volume determines the maximum size of objects a 3D printer can produce in a single job. FDM printers typically offer much larger build volumes compared to SLA systems. Many FDM machines support build areas up to 600 x 600 x 500 mm, making them suitable for medium to large parts, functional prototypes, and batch production. This scalability allows users to print both small and large models without significant limitations.

SLA printers, such as the Anycubic Photon and Elegoo Mars, usually feature build volumes in the range of 115 x 65 x 155 mm to 128 x 80 x 120 mm. These smaller build areas restrict the maximum size of individual parts and can complicate the production of larger items. Users often need to split large models into multiple sections, increasing print time and post-processing efforts.

The difference in build volume impacts project scalability. FDM technology excels in applications that require large or multiple parts, while SLA remains the preferred choice for highly detailed, small-scale models.

- FDM: Ideal for large prototypes, functional parts, and batch jobs.

- SLA: Best for small, intricate components where detail is critical.

Surface Finish

Surface finish quality plays a significant role in the final appearance and functionality of 3D printed parts. FDM parts often display visible layer lines and a stair-stepping effect due to the extrusion process. Surface roughness, measured by parameters such as Ra (average roughness), Rq (root mean square roughness), and Rz (maximum height of the profile), tends to be higher for FDM prints. These parts frequently require additional smoothing techniques, including sanding, vapor smoothing, or applying coatings, to achieve a more refined look.

SLA parts, by contrast, emerge from the printer with much smoother surfaces. The photopolymerization process enables finer resolution and eliminates the need for filament extrusion, resulting in minimal visible layers. Post-processing for SLA prints is generally limited to light sanding or media blasting to achieve a uniform texture. This inherent advantage makes SLA the preferred option for applications demanding superior surface quality, such as dental models, jewelry, and display prototypes.

SLA technology consistently produces parts with lower surface roughness and better visual appeal compared to FDM, reducing the need for extensive post-processing.

The sla-vs-fdm-3d-printing comparison clearly shows that while FDM offers versatility and scalability, SLA stands out in speed for small parts and delivers unmatched surface finish quality.

Strength and Durability

Strength and durability play a crucial role in determining the suitability of 3D printing technologies for functional parts and engineering applications. FDM and SLA each offer distinct mechanical characteristics due to their unique printing processes and materials.

FDM parts display anisotropic mechanical properties. The layer-by-layer construction leads to stronger bonds along the print plane and weaker strength between layers. Standardized 3-point bending tests reveal that FDM parts achieve their highest strength when printed on the long, thin side (x–z plane) and their lowest on the smallest side (y–z plane). Layer thickness also affects strength, but studies show mixed results—sometimes thinner layers improve strength, while other times the effect is negligible or even reversed. Materials such as ABS and carbon-fiber composites can significantly enhance the toughness of FDM prints. Consistency across samples remains high, indicating reliable performance when print orientation and settings are controlled.

| Factor | Observation for FDM Parts (3-point bending test) |

|---|---|

| Build Orientation | Strength varies by orientation; highest strength when printed on the long, thin side (x–z plane), lowest on the smallest side (y–z). |

| Layer Thickness | Mixed effects reported; some studies show decreasing layer thickness improves strength, others find no clear effect or opposite. |

| Sample Consistency | Force-deflection curves consistent across samples for each orientation, indicating reliable test results. |

SLA parts, produced through vat photopolymerization, offer exceptional surface detail but tend to be more brittle than FDM parts. Unless specialized engineering resins are used, SLA prints lack the toughness required for high-impact or load-bearing applications. The brittleness of standard SLA resins limits their use in functional prototypes that demand repeated stress or flexing. In contrast, FDM parts, especially those made with advanced thermoplastics, can withstand moderate mechanical loads and offer better durability for everyday use.

Overall, the sla-vs-fdm-3d-printing comparison shows that FDM excels in mechanical strength and durability, making it the preferred choice for functional parts. SLA stands out in producing highly detailed models but falls short in toughness unless reinforced resins are selected.

Note: FDM parts provide moderate to high strength and durability with the right materials and print settings. SLA parts deliver superior detail but generally remain more brittle, limiting their use in demanding mechanical environments.

Ease of Use and Maintenance

Ease of use and maintenance often influence the adoption of 3D printing technologies in both professional and educational settings. FDM and SLA printers differ significantly in their day-to-day operation, post-processing, and upkeep requirements.

| Factor | FDM Printers | SLA Printers |

|---|---|---|

| Ease of Use | Easier print removal; simpler post-processing | More complex print removal; requires cleaning with isopropyl alcohol |

| Maintenance | Regular cleaning of nozzles, belts, lubrication; less costly | Frequent resin tank replacements; requires wash and cure machines |

| Cost of Upkeep | Lower; filament spools around $25 or less | Higher; resin and accessories add to cost |

| Features Improving Ease | Auto bed leveling, intuitive software, strong community support | Same features improve ease but post-processing more involved |

| User Emphasis | Reliable, affordable technology; user-friendly interfaces; accessible training to reduce frustration | Same user needs but with added complexity in maintenance and post-processing |

FDM printers offer a more straightforward user experience. Print removal is typically easy, and post-processing usually involves only support removal and light sanding. Maintenance tasks include cleaning nozzles, checking belts, and lubricating moving parts. These activities are relatively inexpensive and can be performed every 10–20 hours of printing. Features such as auto bed leveling and intuitive software interfaces further enhance usability. A strong online community provides accessible training and troubleshooting resources, which helps users overcome challenges quickly.

SLA printers require more involved post-processing. Users must wash prints in isopropyl alcohol and cure them under UV light. Maintenance includes frequent resin tank replacements and cleaning to prevent contamination. The cost of upkeep is higher due to the price of resins and additional accessories like wash and cure stations. Despite similar advancements in software and automation, the complexity of handling liquid resins and the need for protective equipment add to the learning curve.

- 69% of users seek more reliable and affordable 3D printing technology.

- Common challenges include complex software and calibration, which can lead to print failures.

- Features like auto bed leveling and user-friendly software improve the experience for both FDM and SLA users.

- Regular maintenance, including cleaning, lubrication, and calibration, extends printer lifespan and ensures consistent print quality.

- Predictive maintenance using analytics and AI can help optimize service schedules and reduce downtime.

sla-vs-fdm-3d-printing: Application Scenarios

Prototyping and Design

Fused Deposition Modeling (FDM) dominates the prototyping and design landscape. Designers and engineers often select FDM for its affordability, rapid turnaround, and material versatility. FDM supports a wide range of thermoplastics, such as PLA, ABS, and Nylon, which enables the creation of functional prototypes that closely mimic end-use products. Teams can iterate designs quickly, reducing development risks and costs. In-house FDM printers allow same-day delivery of prototypes, streamlining decision-making and accelerating product development. Compared to traditional methods like CNC milling, FDM offers lower costs and shorter lead times.

| Technology | Description | Reasons for Preference in Prototyping |

|---|---|---|

| FDM | Extrudes thermoplastic filament layer by layer | Low cost, wide material options, ease of use |

| SLA | Cures liquid resin with UV light | High precision, smooth finish, higher cost |

| SLS | Fuses powdered materials with a laser | Strong, complex parts, higher cost |

While SLA provides superior detail and surface finish, its higher material costs and limited resin options make it less common for early-stage prototyping.

Functional Parts and Engineering

FDM and SLA both serve functional and engineering applications, but each excels in different areas. FDM stands out for mechanical parts, tools, and fixtures due to its broad selection of strong thermoplastic filaments, including fiber-reinforced options. Engineers use FDM to produce full-size, ready-to-use components for aerospace, automotive, and manufacturing. Larger build volumes and the ability to print with high-strength materials make FDM ideal for demanding environments.

SLA, on the other hand, delivers unmatched precision and surface quality. Industrial SLA printers, equipped with engineering-grade resins, produce parts with tight tolerances and smooth finishes. These characteristics benefit industries requiring intricate geometries, such as dental, medical, and electronics. However, standard SLA resins remain brittle, so only specialized resins are suitable for parts under mechanical stress.

Tip: For functional prototypes that require strength and durability, FDM is usually the preferred choice. For parts demanding fine detail and accuracy, SLA offers clear advantages.

Hobby, Education, and Miniatures

Hobbyists, educators, and miniature enthusiasts weigh several factors when choosing between FDM and SLA. FDM printers appeal to beginners and schools because they use inexpensive, widely available filaments and offer straightforward operation. These machines produce strong, durable models quickly, making them suitable for classroom projects and general hobby use.

SLA printers attract users who prioritize detail and surface finish. Miniature painters and modelers favor SLA for its ability to capture fine features and deliver smooth surfaces. However, SLA requires more post-processing, involves higher material costs, and demands careful handling of resins.

| Feature | FDM 3D Printing | SLA 3D Printing |

|---|---|---|

| Resolution & Detail | Lower accuracy, visible layer lines | High resolution, smooth finishes |

| Material Cost | Inexpensive thermoplastics | More expensive, messier resins |

| Print Speed & Workflow | Faster for simple models, easy setup | Slower, more complex workflow |

| Part Strength | Strong, durable | Less tough, more brittle |

| Ease of Use | Beginner-friendly, flexible | Requires careful handling, more post-processing |

| Applications | Hobby, education, functional models | Miniatures, jewelry, detailed educational models |

SLA shines in applications where fine detail matters most, such as miniatures and jewelry. FDM remains the go-to for cost-effective, robust, and quick prints in educational and hobby settings.

Industrial and Professional Use

Industrial and professional sectors have embraced 3D printing technologies to streamline workflows, accelerate product development, and enable on-demand manufacturing. Both SLA and FDM methods play distinct roles in these environments, each offering unique advantages.

SLA technology uses an ultraviolet laser to cure liquid resin, producing parts with exceptional precision and fine detail. Industries such as dental, jewelry, and medical device manufacturing rely on SLA for models that demand smooth surfaces and tight tolerances. Dental labs print aligners, crowns, and surgical guides with SLA, ensuring accuracy and patient-specific customization. Jewelry designers use SLA to create intricate prototypes and casting patterns, reducing manual labor and improving design fidelity.

FDM technology operates by melting and extruding thermoplastic filaments. This approach offers cost-effectiveness and material versatility, making it ideal for producing robust, functional parts. Manufacturers deploy FDM printers to create jigs, fixtures, and replacement components for machinery. The ability to print complex geometries supports rapid prototyping and functional testing, allowing engineers to iterate designs quickly and reduce time to market.

Industries benefit from both technologies in several ways:

- Healthcare professionals print prosthetics, implants, surgical tools, and anatomical models to aid surgical planning and patient care.

- Aerospace and automotive sectors use 3D printing for lightweight components, custom housings, and rapid prototyping.

- Manufacturing facilities produce on-demand spare parts, reducing inventory costs and minimizing equipment downtime.

- Robotics teams fabricate custom housings, articulated joints, and integrated cable channels to enhance automation projects.

- Educational institutions and workforce training programs teach CAD and 3D printing workflows, preparing students for careers in advanced manufacturing.

Advanced 3D printer software further optimizes print settings, speed, and material usage, enhancing productivity and precision. The choice between SLA and FDM depends on the required balance of detail, strength, and cost efficiency. In the context of industrial and professional use, both technologies drive innovation and flexibility, supporting a wide range of applications beyond traditional manufacturing methods.

sla-vs-fdm-3d-printing: Decision Guide

Key Criteria for Choosing

Selecting the right 3D printing technology requires careful evaluation of several critical factors. Experts recommend that users compare SLA and FDM based on print quality, cost, speed, material options, and application suitability. The following table summarizes these criteria to help guide the decision-making process:

| Criteria | SLA (Stereolithography) | FDM (Fused Deposition Modeling) |

|---|---|---|

| Resolution & Detail | High resolution (25–100 μm layer thickness), excellent surface finish, suitable for fine features and tight tolerances | Lower resolution (100–300 μm layer thickness), struggles with fine details and surface smoothness |

| Production Volume & Speed | Suitable for prototypes and small batches; slower print and post-processing times | Faster printing, suitable for rapid prototyping and single parts |

| Cost | Higher material and machine costs; more post-processing labor required | More affordable materials and machines; lower post-processing effort |

| Material Options | Medical/dental-grade resins available but less durable | Wide range of thermoplastic filaments, generally more durable |

| Build Volume | Typically smaller build volumes | Larger build volumes available |

| Ease of Use | Requires curing and support removal, more complex post-processing | Easier post-processing, manual cleanup |

| Application Suitability | Best for detailed, precise, and aesthetic parts | Best for functional prototypes and parts where mechanical strength is prioritized |

When comparing sla-vs-fdm-3d-printing, users should weigh these criteria according to their project’s requirements. For example, projects that demand high accuracy and a smooth finish may benefit from SLA, while those prioritizing speed and cost-effectiveness may find FDM more suitable.

Professionals often use the following checklist to evaluate their options:

- Speed and Cost: FDM offers faster turnaround and lower expenses, while SLA provides higher detail at a premium.

- Material and Functionality: Assess the available materials and their mechanical properties for the intended application.

- Quality and Resolution: SLA excels in print quality and fine detail, making it ideal for intricate designs.

- Compatibility and Availability: Ensure the chosen printer supports the necessary design files and materials.

These criteria help users balance trade-offs and select the technology that aligns with their goals, budget, and timeline.

Matching Technology to Your Project

Project requirements play a decisive role in determining whether SLA or FDM will deliver optimal results. Each technology brings unique strengths to different types of projects. The table below outlines how specific project needs align with the capabilities of each method:

| Project Requirement | FDM Strengths | SLA Strengths |

|---|---|---|

| Strength & Durability | Excellent for rugged, functional parts | Specialized resins improve durability but can be brittle |

| Precision & Detail | Lower resolution, visible layer lines | High precision, fine details, smooth surfaces |

| Surface Finish | Requires post-processing for smoothness | Very smooth finish, minimal post-processing |

| Build Volume | Larger build volumes available | Smaller build volumes, may require part assembly |

| Cost | More cost-effective, lower material costs | Higher material and processing costs |

| Lead Time | Faster print times, parts ready in ~1 day | Longer lead times due to post-curing (~2 days) |

| Ideal Applications | Functional prototypes, mechanical parts, jigs | Aesthetic models, detailed prototypes, molds |

| Combined Use | Structural components in hybrid projects | Detailed aesthetic parts in hybrid projects |

Projects that require robust, functional parts and quick turnaround often benefit from FDM. This technology excels in producing durable prototypes, mechanical components, and large-scale models at a lower cost. FDM’s wide range of thermoplastic filaments supports applications in engineering, manufacturing, and education.

SLA stands out in projects where fine detail, smooth surfaces, and high accuracy are essential. Designers, dental professionals, and jewelers often choose SLA for intricate models, molds, and aesthetic prototypes. Although SLA involves higher material costs and more complex post-processing, it delivers unmatched surface quality and precision.

Some teams combine both technologies for hybrid projects. For example, they may use FDM to print structural components and SLA for detailed, visually appealing parts. This approach leverages the strengths of each method, resulting in functional and attractive final products.

Tip: Always match the technology to the most critical requirement of your project—whether that is strength, detail, speed, or cost. This strategy ensures the best outcome and maximizes the value of your 3D printing investment.

SLA and FDM 3D printing each serve distinct needs. SLA excels in precision and smooth finishes, while FDM offers affordability and robust material options. Industry professionals advise users to match printer choice to application—such as selecting the Elegoo Mars 4 Ultra for miniatures or the Modix Big 60 V4 for large prototypes. Users should compare technologies by cost, materials, and surface finish, and plan for future trends like AI-assisted optimization. Avoiding common mistakes, such as assuming similar workflows or neglecting safety, ensures successful results.

| Technology | Best Use Case | Cost | Print Quality | Material Options |

|---|---|---|---|---|

| FDM | Fast, affordable prototyping | Low | Moderate | Wide thermoplastics |

| SLA | High-detail, smooth models | Medium | High | Photocurable resins |

Careful planning and understanding of each technology’s strengths help users make informed, effective decisions.

FAQ

What is the main difference between SLA and FDM 3D printing?

SLA uses a UV laser to cure liquid resin, producing high-detail parts. FDM melts and extrudes thermoplastic filament, creating strong, functional parts. Each method suits different project needs.

Which technology offers better surface finish?

SLA delivers smoother surfaces and finer details. FDM prints often show visible layer lines. For applications needing a polished look, SLA provides the best results.

Are SLA prints stronger than FDM prints?

FDM prints usually offer greater strength and durability, especially with engineering-grade filaments. SLA prints excel in detail but tend to be more brittle unless using specialized resins.

How much post-processing do SLA and FDM prints require?

FDM prints need minimal post-processing, often just support removal. SLA prints require washing, UV curing, and careful support removal. SLA post-processing takes more time and involves handling chemicals.