Titanium valves redefine durability and performance in demanding environments, showcasing numerous benefits of titanium valves. Their lightweight structure enhances efficiency, especially in industries like aerospace and automotive, where every ounce matters. Unlike traditional materials, titanium resists corrosion effortlessly, ensuring reliability in harsh conditions. Its high strength-to-weight ratio allows it to endure extreme pressures and temperatures without compromising integrity. This unique combination of properties reduces maintenance needs and extends service life. Whether in chemical processing or marine applications, the benefits of titanium valves consistently deliver unmatched performance and reliability.

Key Takeaways

- Titanium valves are significantly lighter than traditional materials, enhancing efficiency in industries like aerospace and automotive.

- Their exceptional corrosion resistance ensures reliability in harsh environments, reducing the risk of system failures.

- Titanium valves withstand extreme temperatures and pressures, making them ideal for critical aerospace and chemical processing applications.

- Investing in titanium valves leads to reduced maintenance needs, saving costs and minimizing operational disruptions over time.

- Titanium valves’ long-term performance and durability translate to a longer service life, making them a cost-effective choice despite higher initial costs.

- Titanium valves excel in marine applications due to their ability to resist rust and chemical degradation, ensuring longevity in saltwater environments.

- By choosing titanium valves, businesses can enhance operational efficiency and safety, confidently operating in demanding conditions.

Unique Properties of Titanium Valves

High Strength-to-Weight Ratio

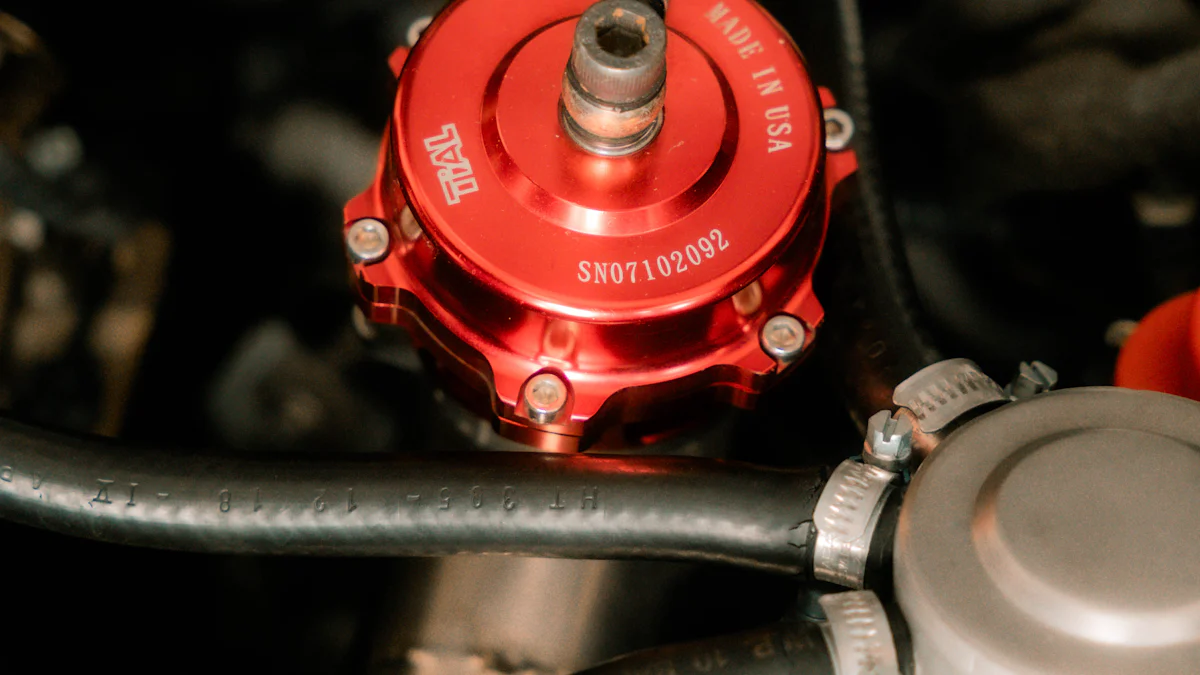

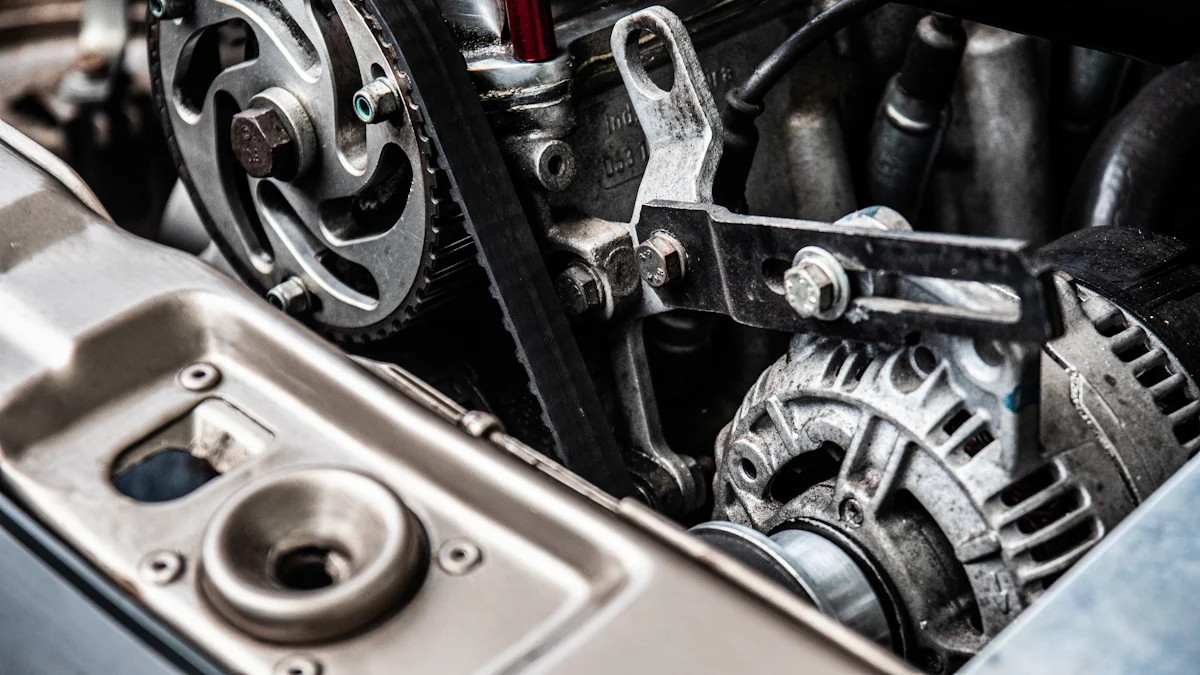

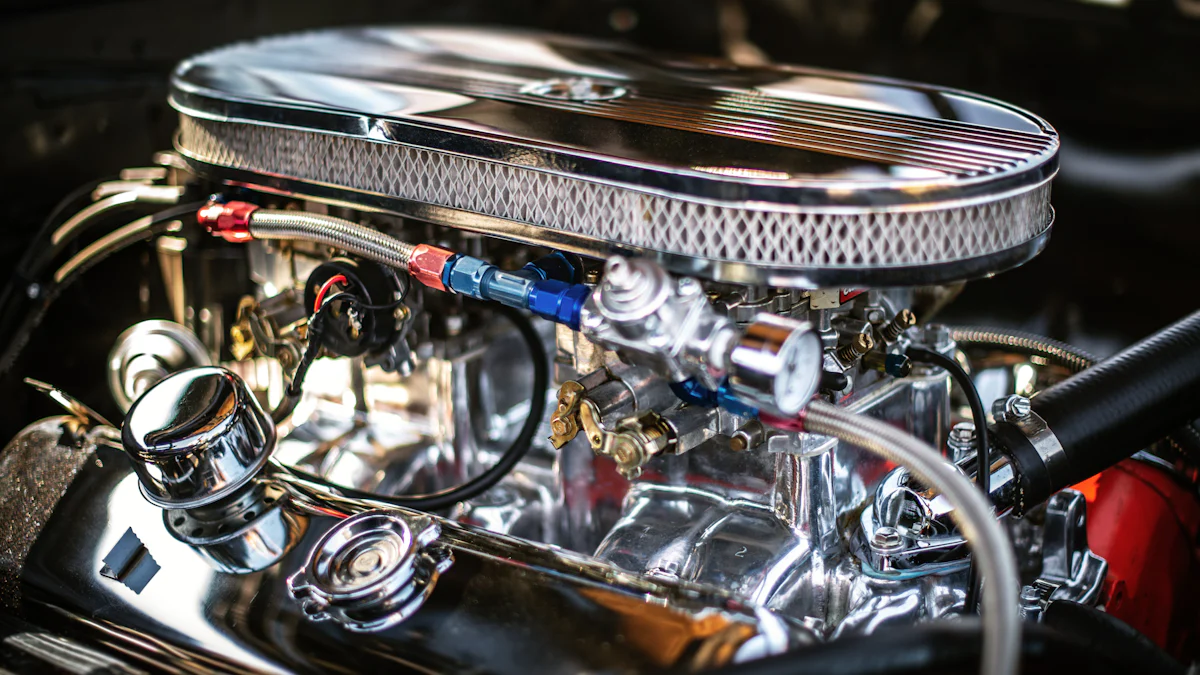

Titanium valves excel due to their remarkable strength-to-weight ratio. This property makes them as strong as some steel alloys while being approximately 45% lighter. In industries like aerospace and automotive, where weight reduction directly impacts performance, this advantage cannot be overstated. Lightweight valves reduce the load on engine components, enabling higher RPM ranges and smoother operation. The reduced mass also allows for more aggressive cam profiles, which can enhance engine power output. By combining strength and lightness, titanium valves deliver unmatched efficiency and reliability.

Exceptional Corrosion Resistance

Corrosion resistance is another defining feature of titanium valves. Unlike traditional materials, titanium naturally resists rust and chemical degradation, even in the harshest environments. This makes it an ideal choice for industries such as marine and chemical processing, where exposure to corrosive substances is common. For example, in the petrochemical sector, titanium valves maintain their integrity despite prolonged contact with aggressive chemicals. This resistance not only extends the lifespan of the valves but also minimizes the risk of system failures, ensuring consistent performance over time.

Temperature and Pressure Resistance

Titanium valves demonstrate exceptional resilience under extreme temperatures and pressures. They retain their structural integrity even in high-performance applications, such as aerospace engines or chemical reactors. This capability stems from titanium’s unique ability to withstand thermal stress without losing strength. In high-temperature environments, where other materials might deform or fail, titanium valves continue to perform reliably. Their durability under pressure further enhances their suitability for critical applications, ensuring safety and efficiency in demanding conditions.

Advantages of Titanium Valves

Long-Term Performance and Durability

Titanium valves excel in delivering long-term performance. Their unique composition ensures resistance to wear, erosion, and fatigue, even in the most demanding environments. Unlike traditional materials like steel or cast iron, titanium maintains its structural integrity under extreme conditions. This durability translates to a longer service life, reducing the need for frequent replacements. For industries such as aerospace and chemical processing, where reliability is critical, titanium valves provide unmatched longevity. By choosing titanium, I have seen how businesses can achieve consistent performance while minimizing operational disruptions.

Reduced Maintenance Needs

One of the standout benefits of titanium valves is their ability to reduce maintenance requirements. Their exceptional corrosion resistance eliminates the common issues associated with rust and chemical degradation. This feature proves invaluable in industries like marine and petrochemical, where exposure to harsh substances is unavoidable. Additionally, titanium’s lightweight nature reduces strain on connected components, leading to less wear and tear over time. From my perspective, investing in titanium valves means fewer maintenance cycles, lower costs, and more efficient operations. This advantage becomes especially evident when compared to traditional materials that demand constant upkeep.

Reliability in Critical Applications

Titanium valves shine in critical applications where failure is not an option. Their ability to withstand extreme temperatures and pressures ensures reliable performance in high-stakes environments. For example, in aerospace engines, titanium valves endure intense thermal stress without compromising functionality. Similarly, in chemical reactors, they resist aggressive substances while maintaining operational efficiency. I have observed how their lightweight yet durable design enhances system reliability across various industries. By incorporating titanium valves, businesses can confidently operate in challenging conditions, knowing their systems are built to last.

Applications of Titanium Valves

Aerospace Industry

In the aerospace industry, I have seen how titanium valves play a critical role in ensuring performance and reliability. Their lightweight nature reduces the overall weight of aircraft engines, which directly improves fuel efficiency and flight range. Titanium’s ability to withstand extreme temperatures and pressures makes it indispensable in jet engines and other high-performance aerospace systems. For example, these valves maintain their structural integrity during intense thermal cycles, ensuring consistent operation even under the most demanding conditions. By incorporating titanium valves, aerospace engineers achieve a balance between durability and efficiency, which is essential for modern aviation.

Marine Industry

The marine industry relies heavily on titanium valves due to their exceptional corrosion resistance. Saltwater environments are notoriously harsh on materials, but titanium’s natural resistance to rust and chemical degradation ensures long-lasting performance. I have observed how these valves excel in applications such as ship engines, desalination plants, and offshore platforms. Their durability reduces the frequency of maintenance, which is crucial for operations in remote or challenging locations. Additionally, the lightweight design of titanium valves minimizes strain on marine systems, enhancing overall efficiency. For industries operating in corrosive marine environments, titanium valves provide unmatched reliability and longevity.

Chemical Processing

In chemical processing, titanium valves stand out for their ability to handle aggressive substances and extreme conditions. I have noticed their widespread use in petrochemical plants, where they resist corrosion from harsh chemicals and maintain operational efficiency. Their high strength-to-weight ratio allows them to endure high pressures without compromising performance. This durability reduces downtime and ensures safety in critical processes. For example, in chemical reactors, titanium valves prevent leaks and failures, safeguarding both equipment and personnel. By choosing titanium valves, chemical processing facilities benefit from enhanced reliability and reduced operational costs, even in the most demanding environments.

Comparison with Other Materials

Titanium vs. Stainless Steel

I have often compared titanium valves to stainless steel ones, and the differences are striking. Titanium valves excel in environments where corrosion resistance is critical. While stainless steel offers decent resistance to rust, titanium’s natural ability to withstand chemical degradation far surpasses it. For example, in marine or chemical processing industries, titanium valves maintain their integrity even after prolonged exposure to harsh substances. Stainless steel, on the other hand, tends to corrode over time, leading to frequent replacements.

The weight difference also stands out. Titanium valves are about 45% lighter than stainless steel. This reduction in weight improves efficiency in applications like aerospace and automotive, where every ounce matters. Additionally, titanium’s high strength-to-weight ratio ensures durability without adding unnecessary bulk. Stainless steel, though strong, cannot match this balance of strength and lightness. From my perspective, titanium valves provide a superior combination of performance and longevity, making them a better choice for demanding applications.

Titanium vs. Aluminum

When comparing titanium valves to aluminum ones, I notice distinct advantages with titanium. Aluminum is lightweight, which makes it a popular choice in some industries. However, titanium matches aluminum’s lightness while offering significantly greater strength. This high strength-to-weight ratio allows titanium valves to perform reliably under extreme pressures and temperatures, where aluminum would likely fail.

Corrosion resistance is another area where titanium outshines aluminum. In environments exposed to saltwater or aggressive chemicals, aluminum corrodes much faster than titanium. For instance, in marine applications, titanium valves endure harsh conditions without compromising performance, while aluminum valves require frequent maintenance or replacement. I have seen how this durability reduces operational costs over time, making titanium a more cost-effective solution despite its higher initial price.

Acknowledging the Cost Factor

I understand that cost often becomes a deciding factor when choosing materials. Titanium valves typically come with a higher upfront cost compared to stainless steel or aluminum. However, I believe this investment pays off in the long run. Titanium’s durability and resistance to wear significantly reduce maintenance and replacement expenses. For industries operating in critical environments, this reliability translates to fewer disruptions and lower operational costs.

Moreover, titanium valves enhance efficiency due to their lightweight design and superior performance. For example, in aerospace or automotive applications, the reduced weight improves fuel efficiency and system reliability. These long-term benefits often outweigh the initial expense. From my experience, businesses that prioritize quality and performance find titanium valves to be a worthwhile investment, delivering unmatched value over time.

Titanium valves deliver exceptional performance and reliability across demanding industries. Their durability and corrosion resistance ensure long-term functionality, even in harsh environments. I have observed how their lightweight design enhances efficiency, particularly in aerospace and marine applications. While the initial cost may seem high, the extended service life and reduced maintenance needs make them a cost-effective choice. Businesses that prioritize operational efficiency and safety consistently benefit from titanium valves. The benefits of titanium valves make them indispensable for industries requiring superior performance and longevity.

FAQ

What advantages do titanium valves have over other materials?

Titanium valves offer several key advantages over traditional materials. Their lightweight nature, combined with a high strength-to-weight ratio, makes them ideal for industries like aerospace and automotive, where reducing weight is critical. Unlike steel or iron, titanium resists corrosion exceptionally well, even in harsh environments such as marine or chemical processing. This corrosion resistance ensures a longer lifespan and reduces the risk of equipment failure. Additionally, titanium valves withstand high temperatures and pressures, making them suitable for demanding applications. While the initial cost may be higher, the long-term benefits, including reduced maintenance and enhanced reliability, make titanium valves a superior choice.

What benefits do titanium valves provide in critical industry applications?

Titanium valves excel in critical applications due to their durability and reliability. They resist corrosion better than materials like stainless steel or brass, ensuring longer service life in challenging environments. Their lightweight design reduces strain on connected components, enhancing overall system efficiency. In industries such as aerospace, chemical processing, and marine, titanium valves maintain performance under extreme conditions, including high temperatures and pressures. This combination of properties ensures operational safety and efficiency, making titanium valves indispensable in high-stakes environments.

Why are titanium valves considered an excellent investment for industries?

Titanium valves represent a smart investment for industries requiring durable and reliable components. Their exceptional resistance to corrosion and mechanical wear reduces the need for frequent replacements, saving costs over time. Titanium’s high strength and lightweight nature enhance system performance, particularly in aerospace and automotive applications. Additionally, their ability to withstand harsh environments ensures safety and efficiency in operations. While the upfront cost may be higher, the long-term savings from reduced maintenance and downtime make titanium valves a cost-effective solution for many industries.

How do titanium valves enhance performance in the aerospace industry?

In the aerospace industry, titanium valves play a crucial role in improving performance. Their lightweight design reduces the overall weight of aircraft engines, directly enhancing fuel efficiency and flight range. Titanium’s ability to endure extreme temperatures and pressures ensures reliability in jet engines and other high-performance systems. By maintaining structural integrity during intense thermal cycles, titanium valves contribute to consistent operation and safety. These features make titanium valves a preferred choice for modern aviation.

What makes titanium valves suitable for marine applications?

Titanium valves are highly suitable for marine applications due to their exceptional corrosion resistance. Saltwater environments are notoriously harsh on materials, but titanium naturally resists rust and chemical degradation. This durability ensures long-lasting performance in ship engines, desalination plants, and offshore platforms. Additionally, their lightweight design reduces strain on marine systems, enhancing efficiency. For industries operating in corrosive marine environments, titanium valves provide unmatched reliability and longevity.

How do titanium valves reduce maintenance needs?

Titanium valves significantly reduce maintenance requirements through their unique properties. Their corrosion resistance eliminates issues like rust and chemical degradation, which are common with traditional materials. This feature proves invaluable in industries exposed to harsh substances, such as petrochemical and marine sectors. Furthermore, their lightweight nature minimizes wear and tear on connected components, extending the lifespan of the entire system. By choosing titanium valves, businesses can lower maintenance cycles, reduce costs, and improve operational efficiency.

Are titanium valves cost-effective despite their higher initial price?

Yes, titanium valves are cost-effective in the long run. While their upfront cost may be higher than materials like stainless steel or aluminum, their durability and resistance to wear result in significant savings over time. Titanium valves require less frequent maintenance and replacements, reducing operational disruptions and associated costs. Additionally, their lightweight design enhances efficiency, particularly in industries like aerospace and automotive. These long-term benefits often outweigh the initial expense, making titanium valves a worthwhile investment.

What industries benefit the most from titanium valves?

Several industries benefit greatly from titanium valves, including aerospace, marine, chemical processing, and automotive. In aerospace, their lightweight design improves fuel efficiency and performance. In marine environments, their corrosion resistance ensures durability against saltwater exposure. Chemical processing facilities rely on titanium valves for their ability to handle aggressive substances and high pressures. Automotive industries use them in high-performance engines to enhance reliability and reduce weight. Across these sectors, titanium valves deliver unmatched performance and longevity.

How do titanium valves perform under extreme conditions?

Titanium valves excel under extreme conditions due to their unique properties. They retain structural integrity at high temperatures, making them suitable for applications like jet engines and chemical reactors. Their resistance to high pressures ensures reliable performance in demanding environments. Additionally, titanium’s corrosion resistance allows it to withstand exposure to aggressive chemicals and harsh environments without degrading. These qualities make titanium valves a dependable choice for critical applications.

What role do titanium valves play in improving fuel efficiency?

Titanium valves contribute to improved fuel efficiency by reducing the overall weight of systems they are part of. In automotive and aerospace applications, their lightweight design decreases the load on engines, allowing for smoother operation and higher RPM ranges. This reduction in weight translates to better fuel economy and enhanced performance. By incorporating titanium valves, industries can achieve greater efficiency while maintaining reliability and durability.