Unlocking the Cost Puzzle of 3D Printed Titanium

Imagine designing a component that combines supreme strength with feather-light weight—attributes that are crucial in fields ranging from aerospace to high-end sports equipment. Now, imagine achieving this with the magic of 3D printing using titanium, one of the most robust and corrosion-resistant metals available. While the allure of creating complex, customized titanium parts is undeniable, the associated costs can often lead to sticker shock. Why is 3D printed titanium so expensive, and are there ways to manage these costs effectively?

Breaking Down the Costs of 3D Printed Titanium

The financial outlay for 3D printing with titanium is influenced by a variety of factors, making it a premium option within the realm of additive manufacturing. Firstly, the raw material—titanium powder—is notoriously expensive, typically priced between $300 to $600 per kilogram. This steep cost is attributed to the sophisticated methods required to produce a powder fine enough for the precise demands of 3D printing.

Service providers, utilizing advanced techniques such as Direct Metal Laser Sintering (DMLS), typically charge between $35 to $50 per cubic centimeter of printed titanium. For perspective, a solid cube measuring 10cm on each side would cost between $35,000 and $50,000 to produce. This price range is reflective not only of the material costs but also the significant capital investments in industrial-grade 3D printers, which often exceed $1 million. Moreover, the inherently slow production rates of these printers add to the cost by limiting throughput.

Navigating Through the High Costs

While the sticker price of 3D printed titanium might be daunting, understanding the contributing factors can help in planning and budgeting for projects. The high cost of the titanium powder itself is a major factor, driven by complex production techniques. However, innovations in powder production, such as those being developed by companies like Metalysis and PyroGenesis, promise to reduce these costs by up to 17% by 2024.

Furthermore, alternative technologies like Directed Energy Deposition (DED), which utilizes less costly titanium wire, offer faster production times at a reduced expense, although they may sacrifice some precision and surface quality. These alternatives illustrate the evolving landscape of titanium 3D printing, highlighting efforts to make this technology more accessible and economically feasible for a broader range of applications.

In summary, while the current costs associated with 3D printed titanium are high, they are anchored in the material’s intrinsic value and the sophisticated technology required to mold it. For industries and applications where the unique properties of titanium are essential, these costs are a worthwhile investment. Meanwhile, ongoing advancements in technology and materials science continue to gradually bring down expenses, promising a future where 3D printed titanium is more affordable and accessible.

Are there any companies offering more affordable titanium 3D printing services?

Yes, there are several companies offering more affordable titanium 3D printing services compared to traditional service providers. Here are a few examples:

- Xometry(USA): They offer titanium 3D printing services starting at around $35 per cubic cm. While still expensive, this is relatively more affordable than some other providers that charge $50+ per cubic cm. Xometry leverages a distributed network of manufacturing partners to offer competitive pricing.

- 3DCompare(USA): This online manufacturing platform provides quotes from various 3D printing services. For titanium (CL41Ti) printing, their pricing starts at $35.71 per cubic cm with a $176 minimum cost per order. They allow you to compare prices across different suppliers.

- JHMIM(China): This metal 3D printing service based in China offers titanium (Ti64) printing at relatively lower costs by leveraging their industrial-scale operations. While they don’t publicly list pricing, their costs are generally lower than Western suppliers.

- Fathom Manufacturing: As a large U.S. service provider, Fathom can leverage economies of scale to offer somewhat more affordable titanium printing compared to smaller bureaus. They have over 12 DMLS machines dedicated to metal printing.

- Emerging technologies: Companies like Metalysis and PyroGenesis are working on reducing the cost of titanium powders used in 3D printing, which could help lower overall part costs by up to 17% in the coming years according to some estimates.

While still very expensive compared to other metals, these providers aim to make titanium 3D printing more accessible through competitive pricing models, distributed manufacturing networks, and new powder production methods. However, for high volumes of simple geometries, traditional machining may still be more cost-effective for titanium parts currently

More Resources:

Titanium – Source: Wikipedia

Titanium Alloy – Source: Wikipedia

3D Printed Architectural Model –Source:RJ Models

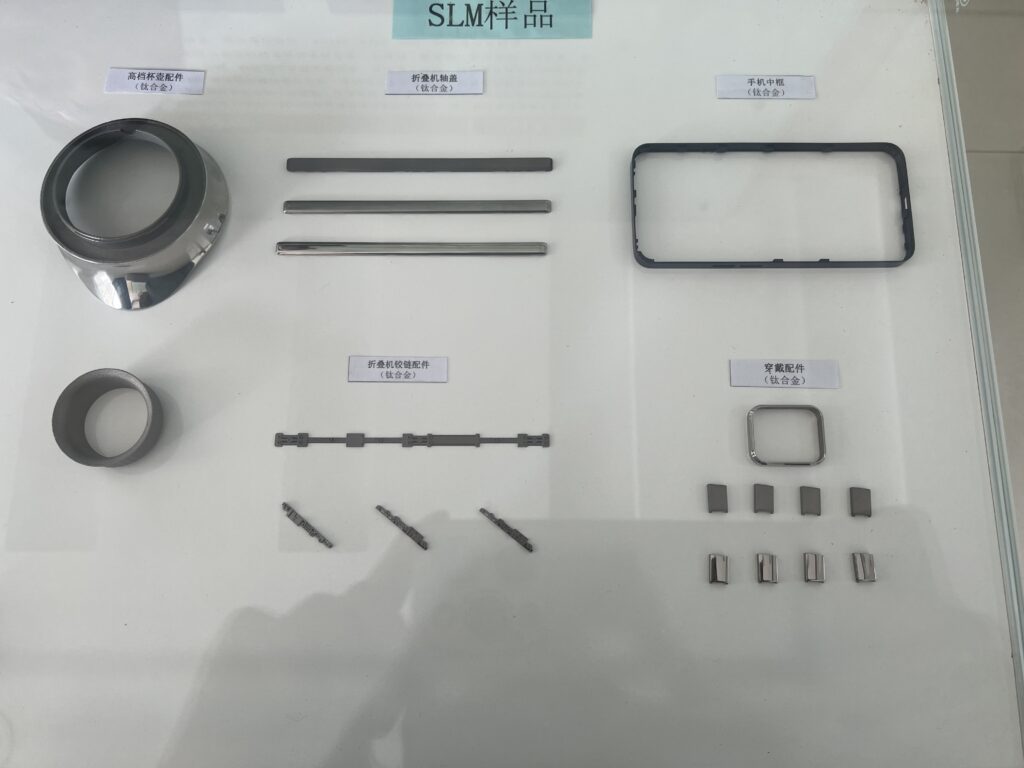

Titanium 3D Printing service – Source: JHMIM

Titanium Injection molding – Source: JHTI